Test-piece torsion test system

A test system and test piece technology, applied in the direction of applying stable torsion to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inability to perform repeated torque loading, cracks, end force and deformation complex, etc. Achieve the effect of easy composite force test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

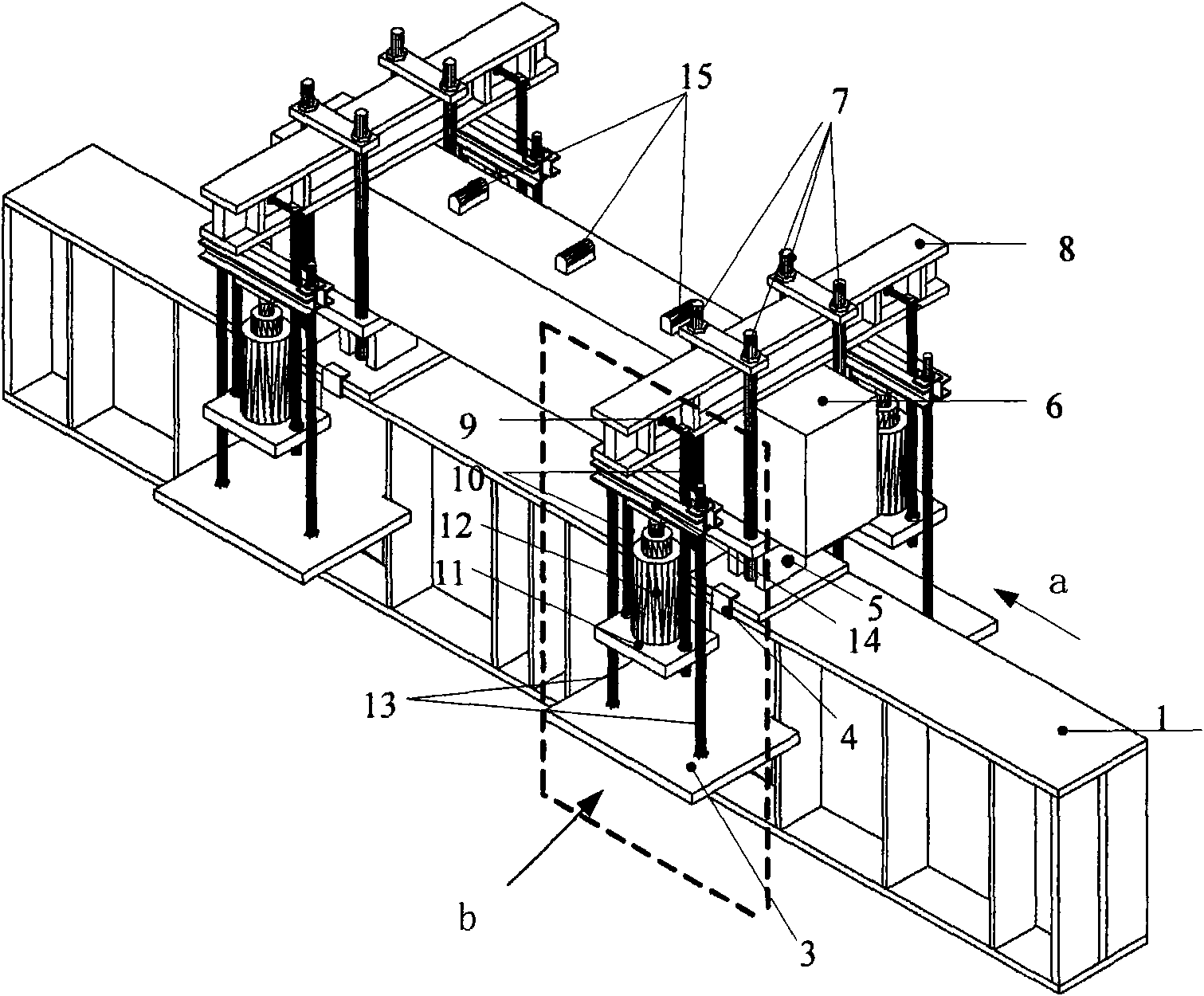

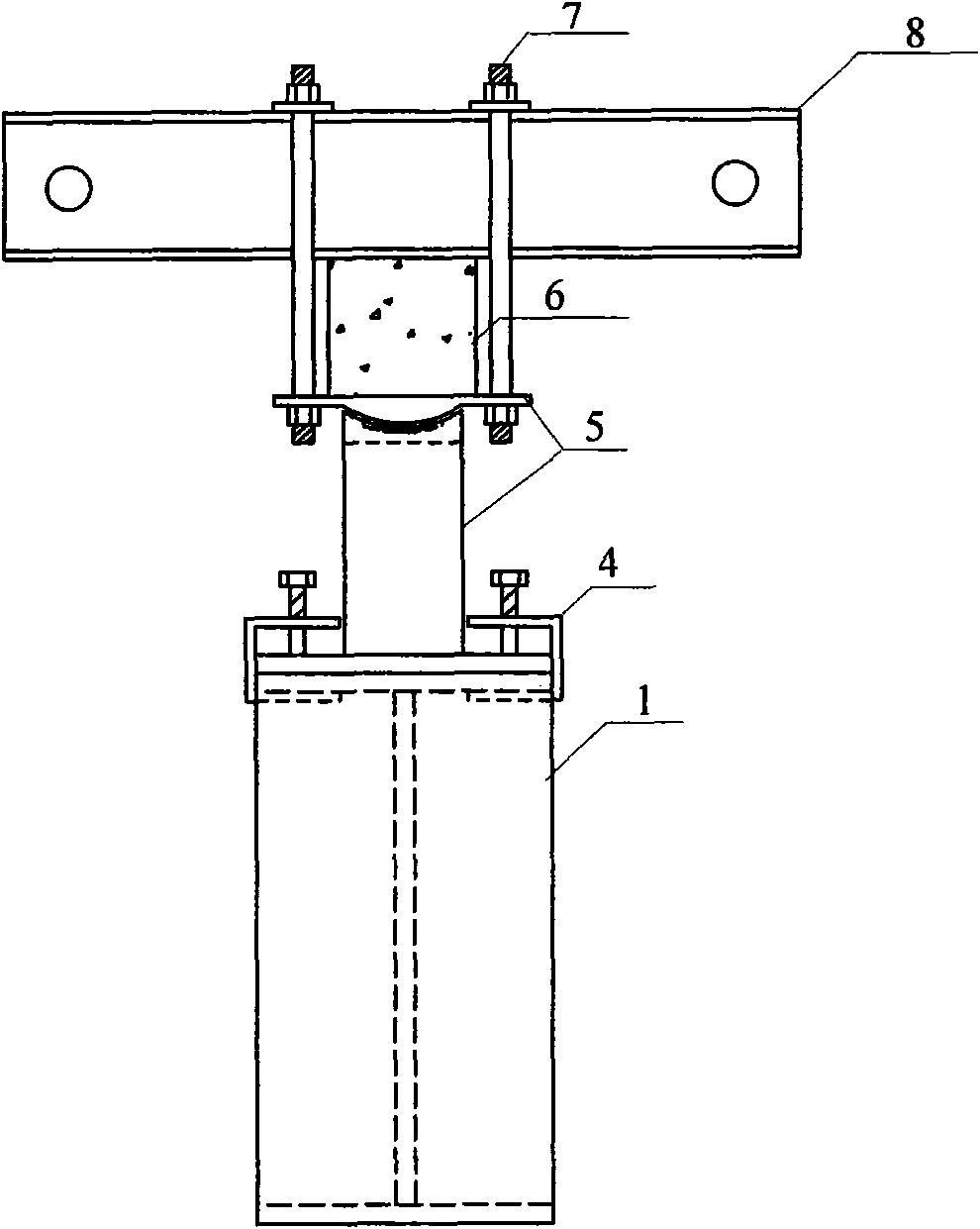

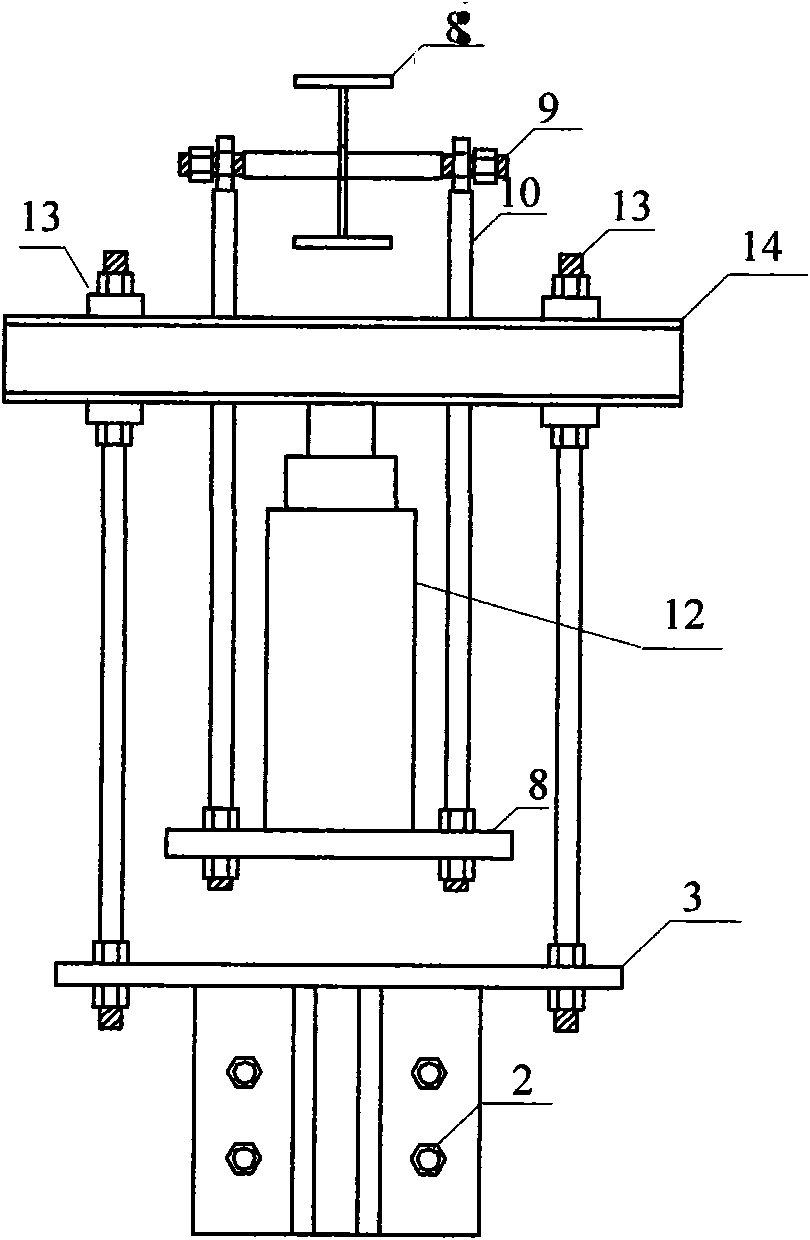

[0038] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0039] The present invention makes two improvements to the test loading system. One is to cancel the fixed end, and both ends of the test piece are loaded by jacks. The problems of stability and inability to rotate freely are solved by setting arc supports. In this way, the damage phenomenon of fixed end nodes that may occur due to asymmetric loading at both ends in some current tests will not appear. Due to the symmetrical application of torque at both ends, it can truly simulate the free torsion of components in actual engineering, the force is clear, and it is easy to analyze. The second is to make a jack loading conversion device, which can realize repeated torque.

[0040] The loading system consists of three parts: vertical support, specimen and its fixing device, jack and its conversion device. For the case of monotonic torque, there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com