Single counterweight type automatic levelling spreader and using method thereof

A level adjustment and level adjustment device technology, which is applied to cranes, load hanging components, walking bridge cranes, etc., can solve problems such as potential safety hazards, large volume and weight, and difficulty in ensuring accuracy, and achieve the safety of personnel and loads Guaranteed, simple mechanical structure, precise level adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, and have no limiting effect on the present invention.

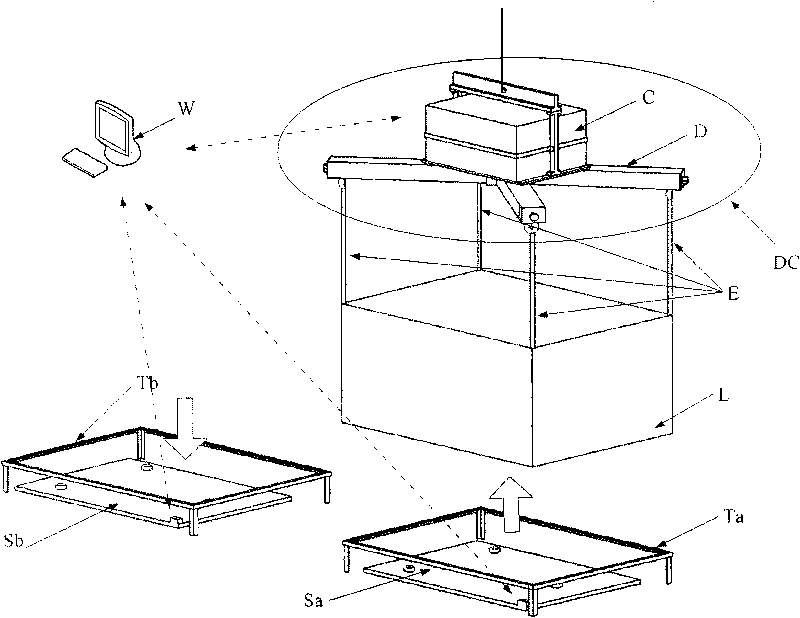

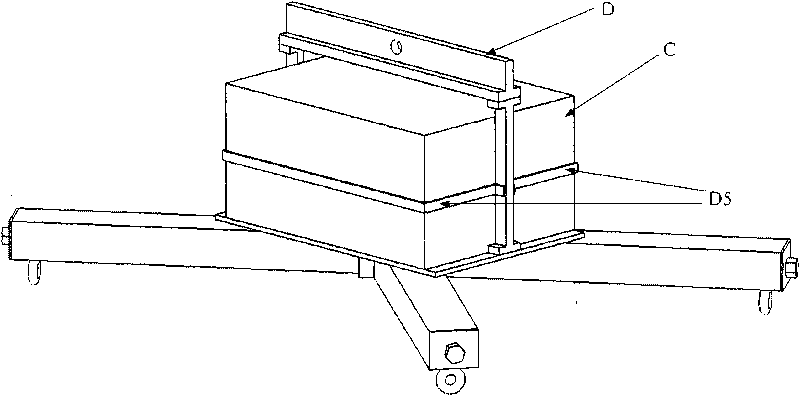

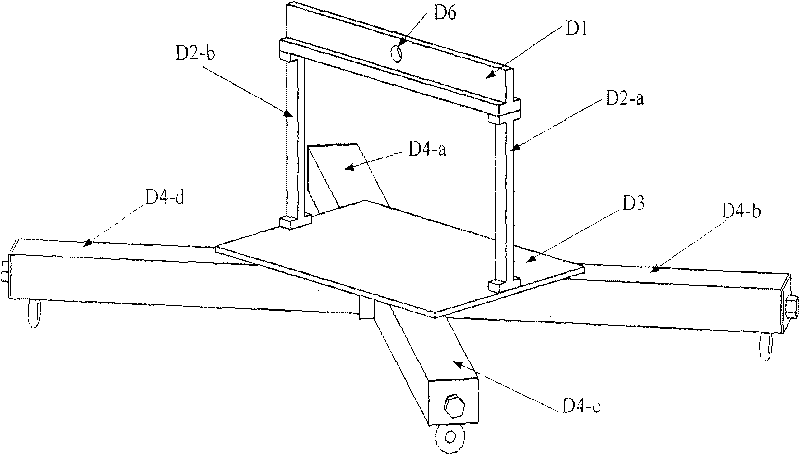

[0080] The embodiments of the present invention provide a single-counterweight type automatic horizontal adjustment hoisting device system for loads requiring high hoisting accuracy. The spreader system of the present invention only considers the situation that the docking surface is smooth during assembly, such as a reactor building. Such as figure 1 As shown, it is a schematic diagram of the overall structure of the single-counterweight type automatic level adjustment spreader system of the present invention. The overall structure of the spreader system of the present invention can be divided into several parts: computer W, load-bearing spreader D, automatic level adjustment device C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com