Automatic PCB production line

A PCB board and production line technology, applied in the field of automated PCB board production line, can solve the problems of adverse health effects of workers in the production environment, increased labor costs, and difficulty in ensuring safety, and achieves strong versatility and practicability, improved production safety factor, and production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

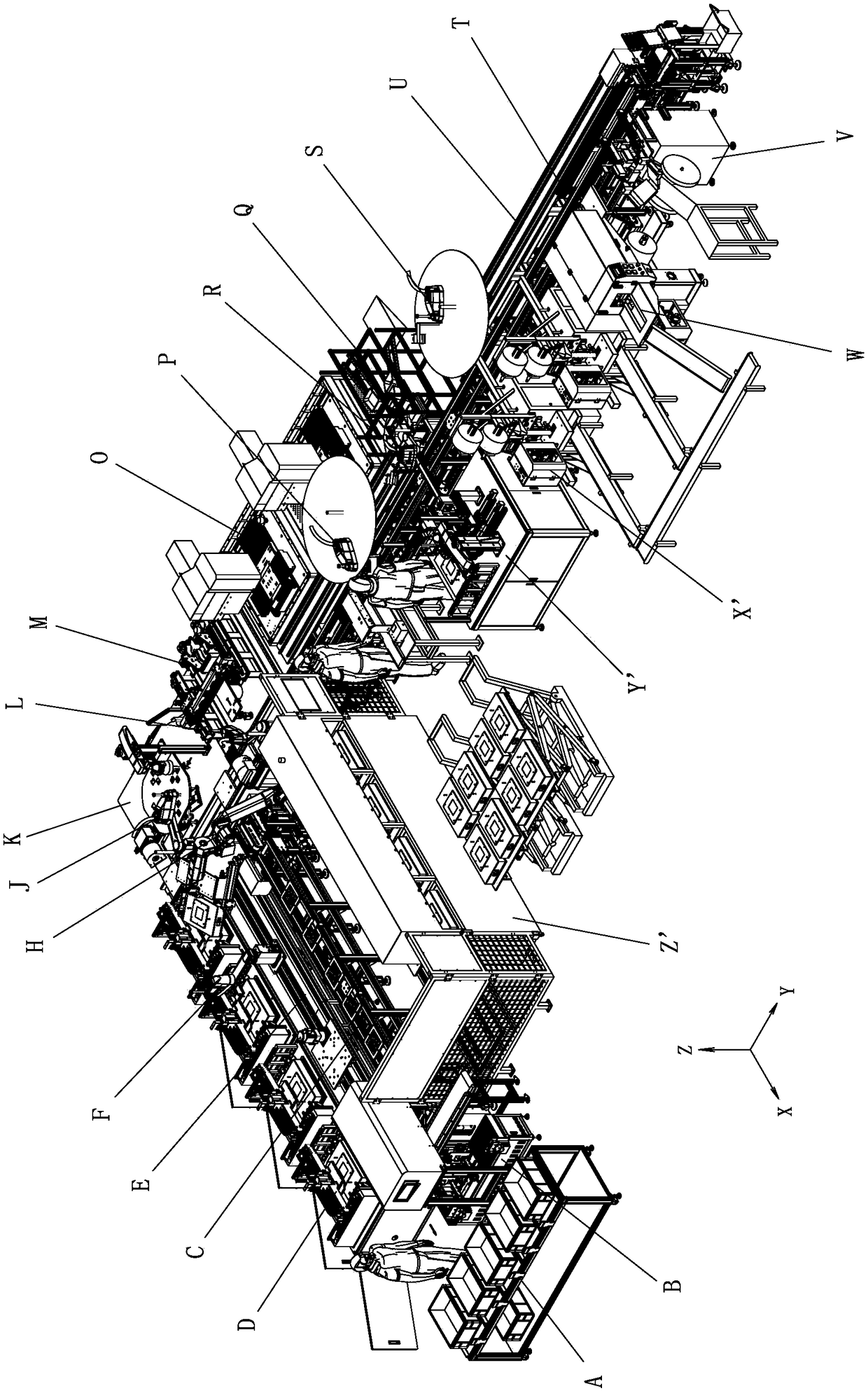

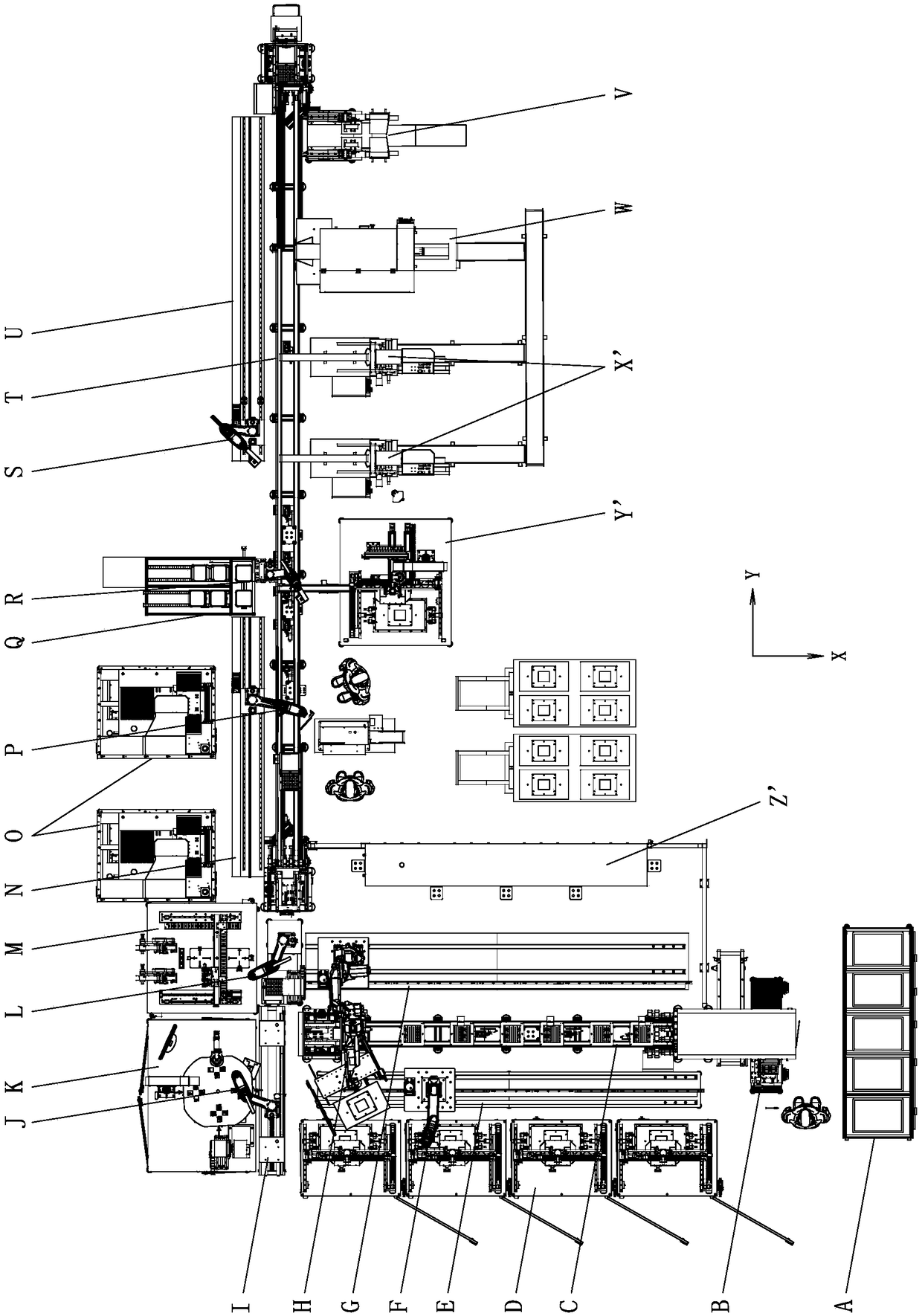

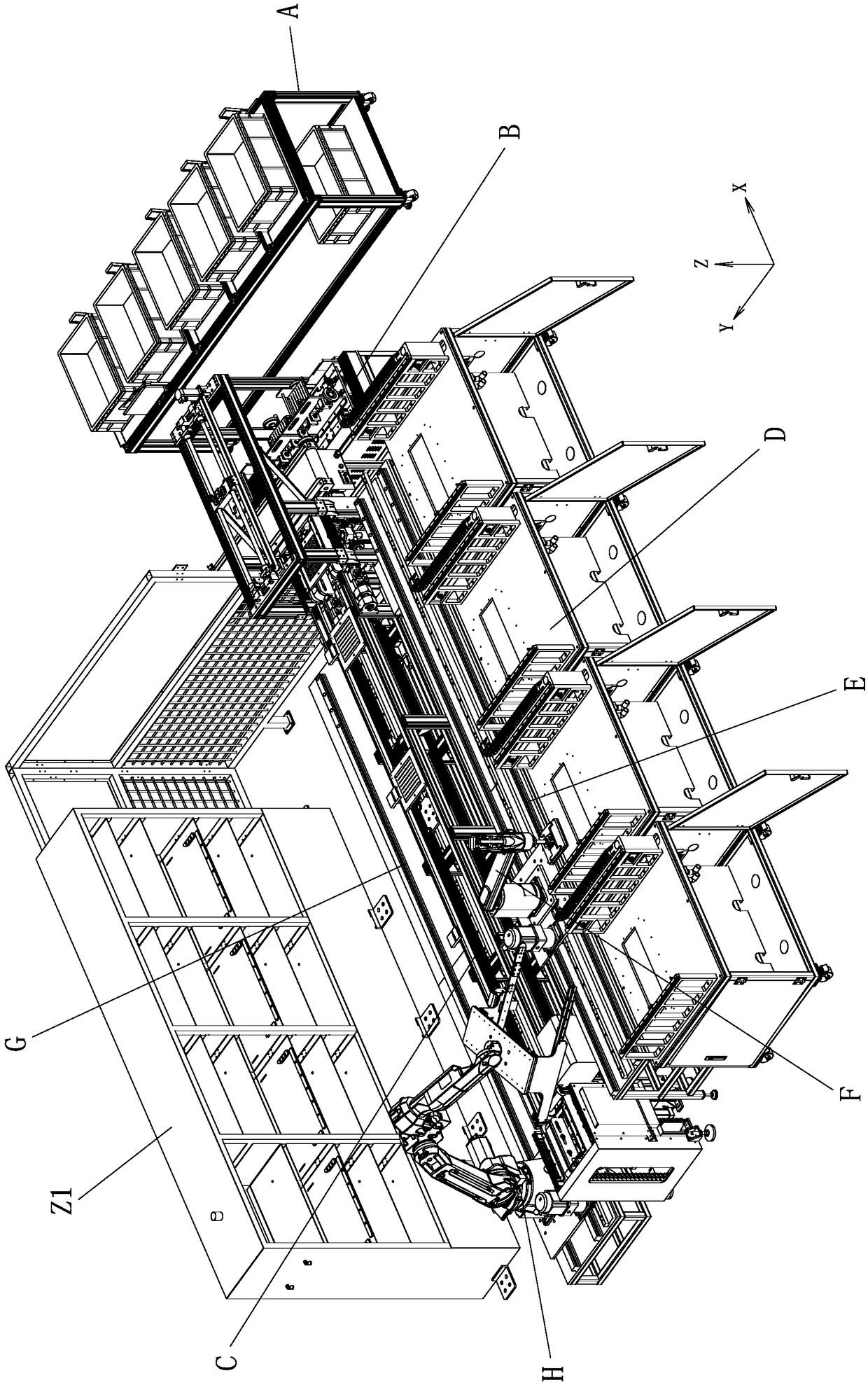

[0080] see figure 1 and figure 2 , the automated PCB board production line, including

[0081] The production conveyor line is used to drive the PCB board to move along the production line, which includes a feeding conveyor line C and a packaging conveyor line T;

[0082] The multi-station feeding equipment B is used to feed the PCB onto the feeding conveyor line C, and the multi-station feeding equipment B is set at the beginning of the feeding conveyor line C;

[0083] PCB board burning equipment D is used to burn PCB boards. There are four sets of PCB board burning equipment D. Material conveying line C side;

[0084] The PCB board coding equipment K is used to code the PCB board, and the PCB board coding equipment K is set at the end of the feeding conveyor line C;

[0085] PCB board gluing equipment M is used for gluing PCB boards. The PCB bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com