Automatic work piece loading-unloading robot

An automatic loading and unloading, robot technology, applied in the direction of manipulator, metal processing, manufacturing tools, etc., can solve the problems of long processing cycle of water heater, low workpiece positioning accuracy, high labor intensity of workers, etc., to save manpower, simple structure, The effect of high repeat positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

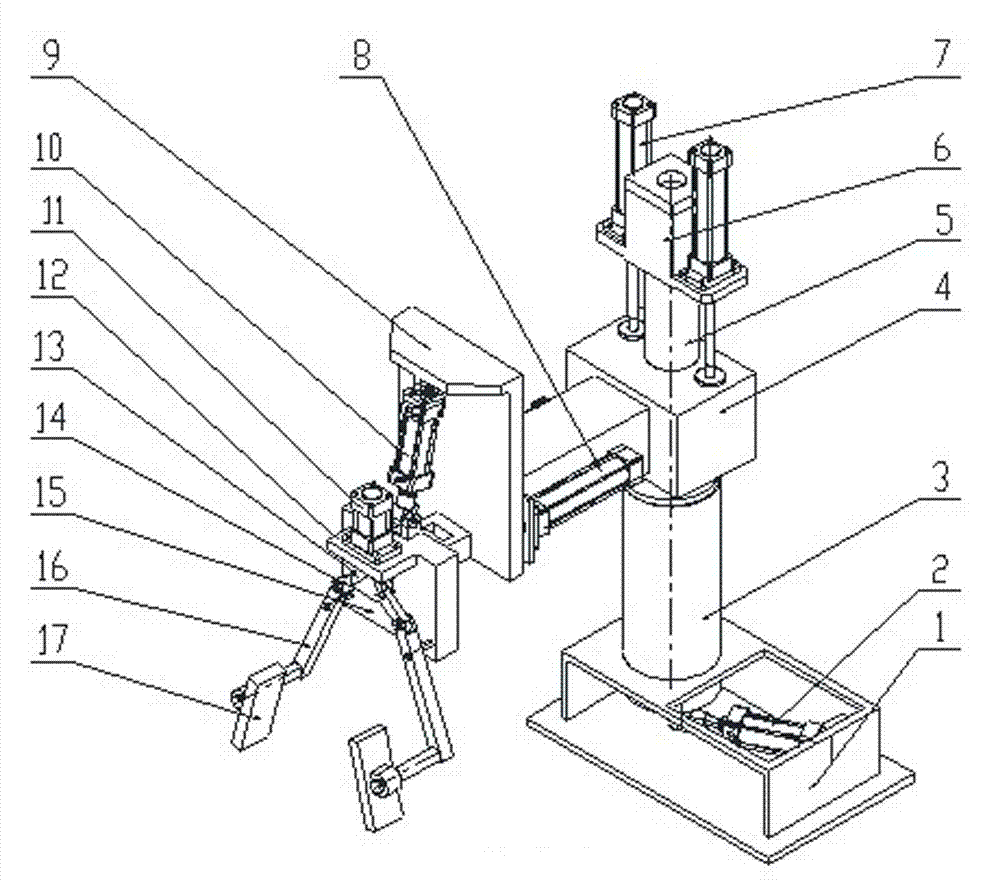

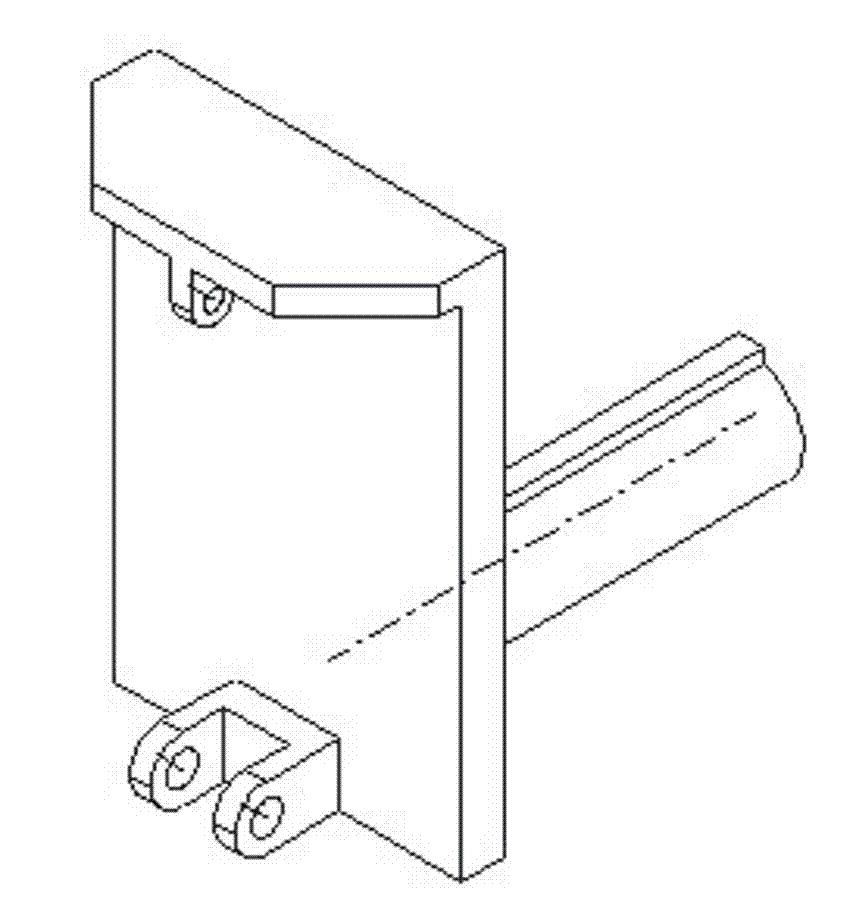

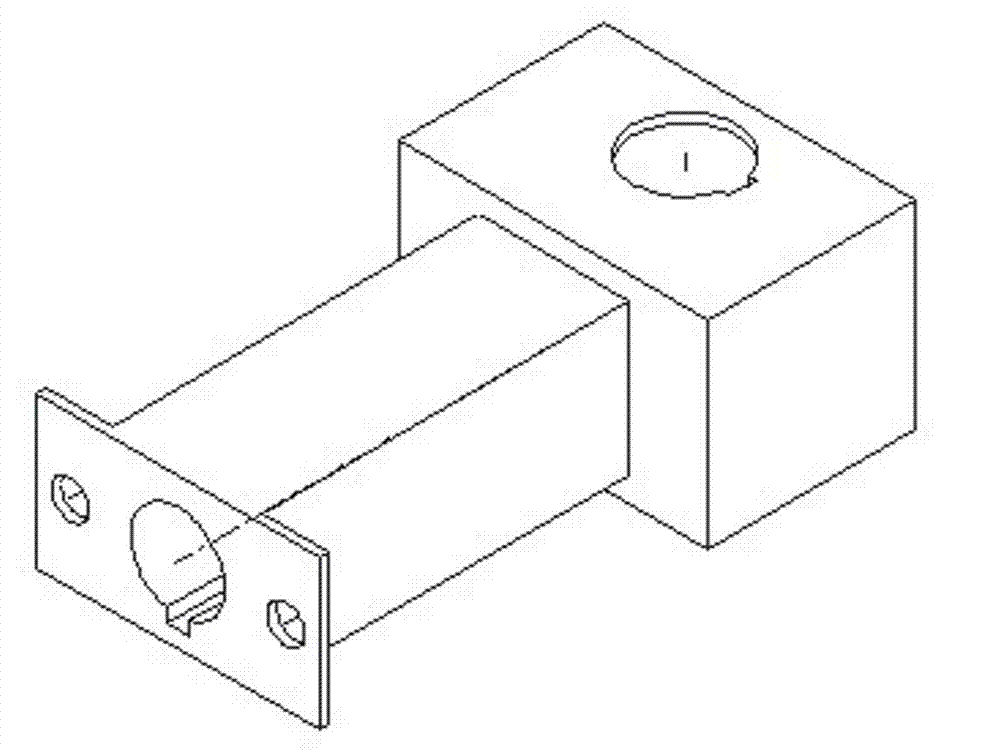

[0018] Such as Figure 1-6 A specific embodiment is shown, which includes a machine base 1, a rotating cylinder or oil cylinder 2, a fixed bushing 3, a lifting frame 4, a rotating shaft 5, a fixed frame 6, a lifting cylinder or an oil cylinder 7, a telescopic air cylinder or an oil cylinder 8, Telescopic frame 9, overturning cylinder or oil cylinder 10, catch and put cylinder or oil cylinder 11, catch and put support 12, slide seat 13, connecting rod 14, overturn support 15, mechanical arm 16 and hold plate 17.

[0019] The fixed shaft sleeve 3 is vertically fixed on the machine base 1, the rotating shaft 5 is inserted into the fixed shaft sleeve 3, the lower end of the rotating shaft 5 extends into the machine base 1, and the rotating cylinder or oil cylinder 2 is arranged in the machine base 1, and the rotating shaft 5 is inserted into the machine base 1. The tail end of the cylinder body of the air cylinder or oil cylinder 2 is hinged with the base 1, and the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com