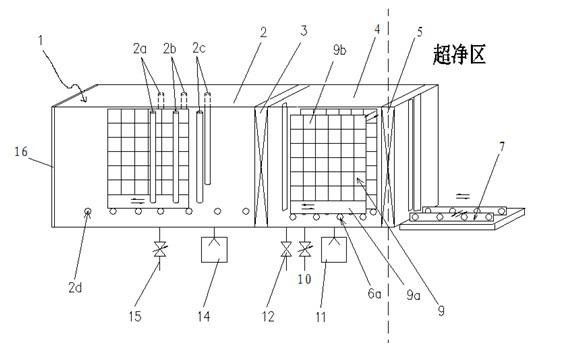

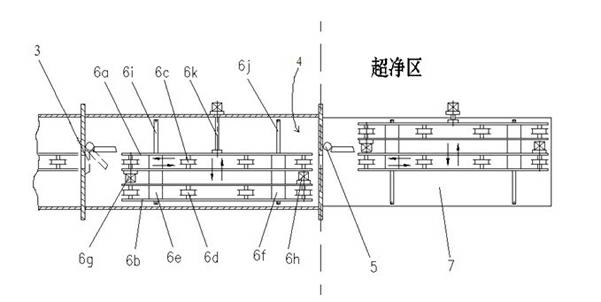

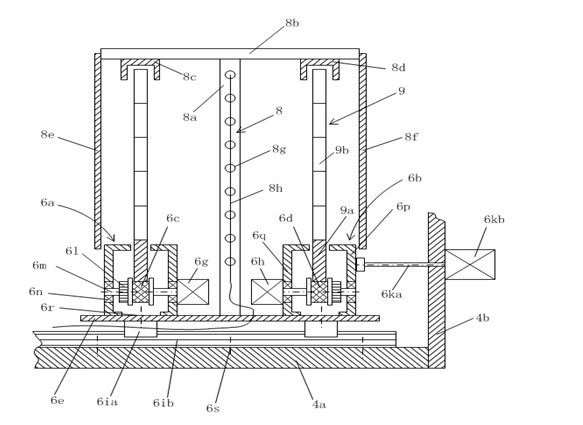

Same end entrance-exit type continuous sputtering film plating device

A sputtering coating and equipment technology, applied in the field of the same-end in-out continuous sputtering coating equipment, can solve the problems of high operating cost, large area, huge equipment, etc. Small, high throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] In the single-end continuous sputtering coating equipment of the present invention, a small ultra-clean table is arranged on one side of the loading and unloading table, and each workpiece rack can be loaded with a ceramic substrate of one square meter. Chromium-copper-silver coating takes about 5-6 minutes per machine, and the equipment occupies two-fifths less than the double-ended machine, the energy consumption is reduced by one-third, and the cost of the equipment is reduced 40%, and its annual throughput is almost the same as that of double-ended continuous sputtering equipment. To test the quality of the film, its uniformity, tensile strength, welding resistance and other indicators are the same as those of the double-ended machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com