Method and devices to limit a creep of mechanical fasteners

a technology of mechanical fasteners and creep, applied in the direction of threaded fasteners, machines/engines, washers, etc., can solve the problems of increasing the leakage rate, and complex structural durability of the structural system, so as to increase the leakage tightness of critical facilities and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

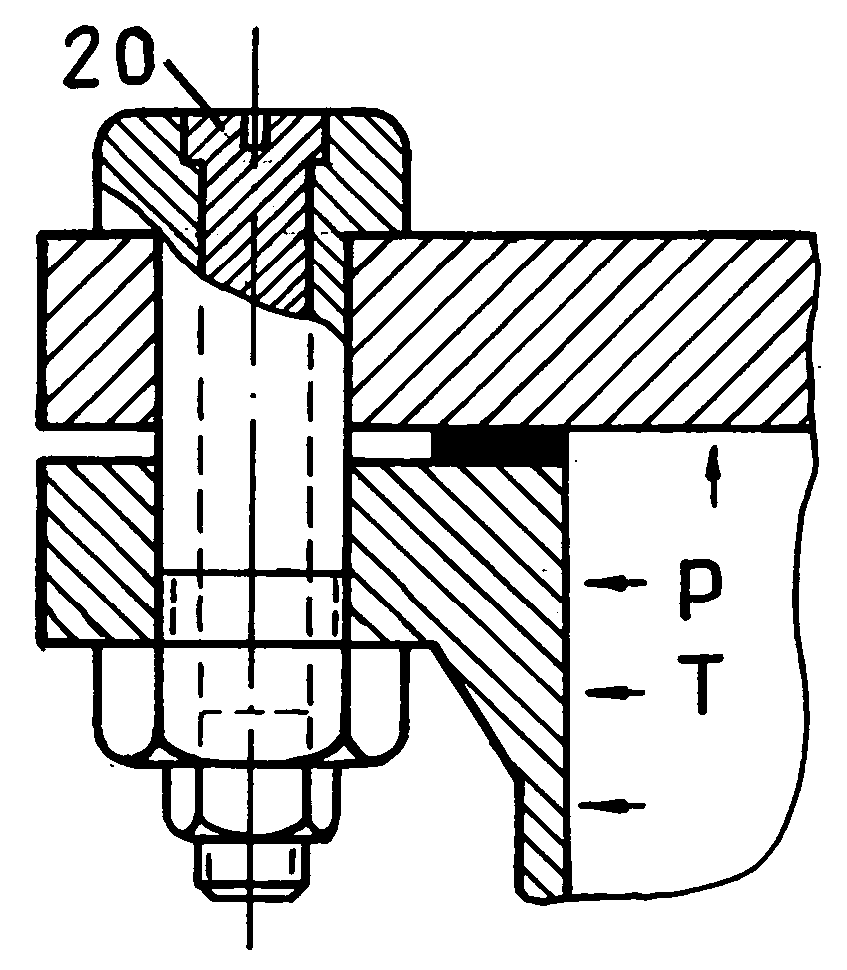

—FIG. 3 IS PREFERRED EMBODIMENT

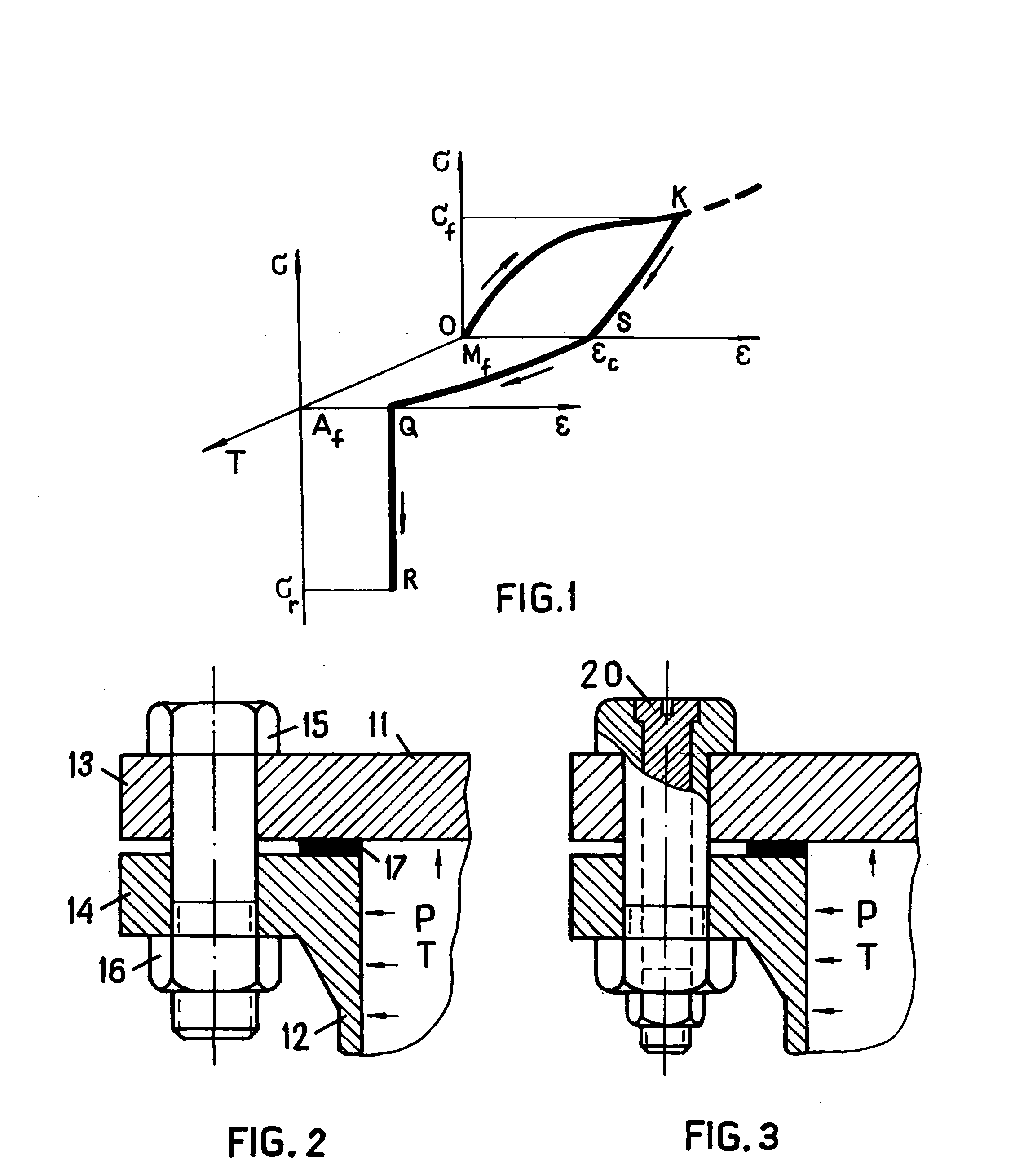

[0035]FIG. 1 is three-dimensional stress-strain-temperature diagram σ-ε-T showing a behavior of power element of shape memory alloy during the formation of shape-memorized deformation along with its constrained recovery. An initial point “O” corresponds to temperature below Mf at which the transformation of martensite finishes. The stress-induced martensite is obtained during loading-unloading of the power element that is presented at the stress-strain diagram σ-ε at the rear graph in FIG. 1. The point K corresponds to the final stress σf before unloading, and the point S corresponds to the final strain εc after unloading.

[0036] The strain εC is a conserved residual shape-memorized deformation of the power element of shape memory alloy. This deformation tries to be recovered during the heating to the temperature Af (point Q at the front graph in FIG. 1 corresponding to austenite state of the power element), but its shape recovery is stopped by rigid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com