Energy-saving electrocar for loading unloading and transporting

A technology for loading, unloading, and electric vehicles, which is applied in the direction of electric vehicles, electric traction, vehicle parts, etc., can solve the problems of complicated layout of the whole machine, complex structure and manufacturing process of the whole machine, huge inventory of maintenance spare parts, etc. Minimize and save energy, improve operating efficiency, and increase the effect of speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

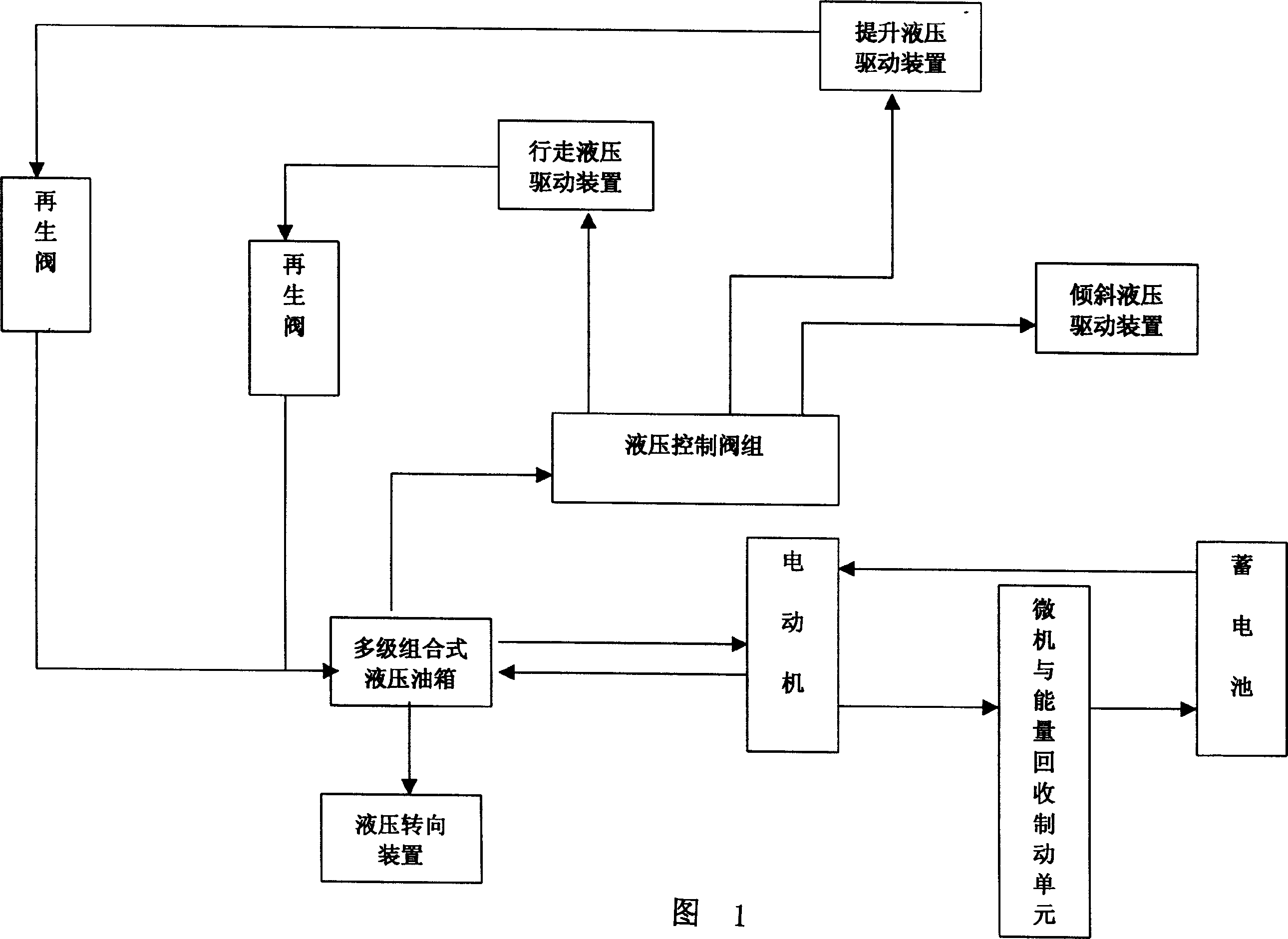

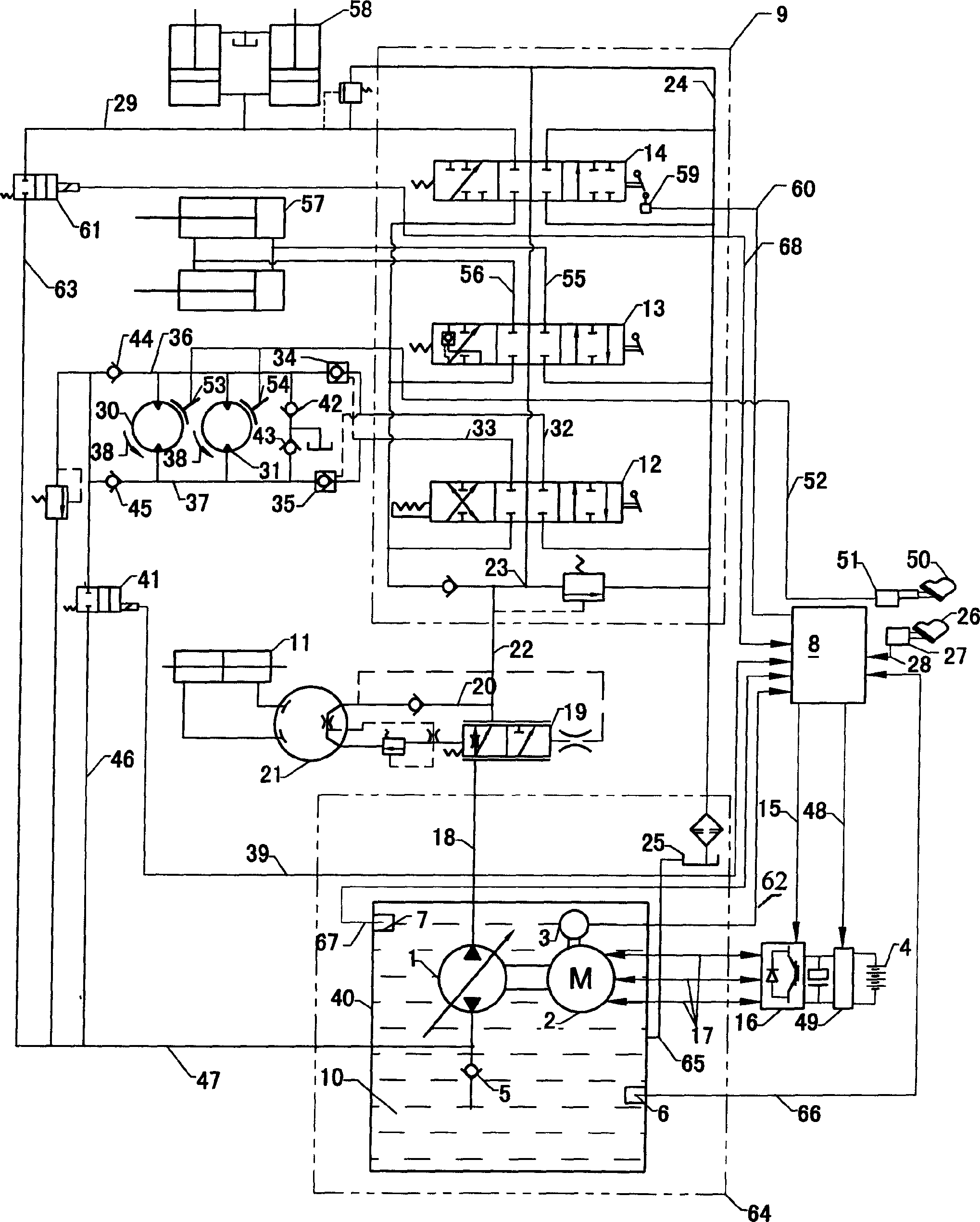

[0070] First please refer to Figs. 1 and 2, the present invention includes a multi-stage combined hydraulic oil tank, a hydraulic steering device, a traveling hydraulic driving device, a tilting hydraulic driving device, a lifting hydraulic driving device, energy recovery and a microcomputer control unit. The multi-stage combined hydraulic oil tank 64 is composed of a high-level hydraulic oil tank 25 and a low-level hydraulic oil tank 40. In the low-level hydraulic oil tank 40, the speed sensor 3 connected coaxially with the motor 2, the variable pump 1, the one-way valve 5, and the oil temperature sensor 6 , liquid level sensor 7, hydraulic oil 10 and other components. The speed sensor 3 on the shaft side of the motor 2 detects the rotation speed of the motor 2 and feeds back the rotation speed signal 62 to the microcomputer control unit 8 to form a closed-loop control. The hydraulic control valve group 9 is a three-position six-way valve composed of a travel reversing contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com