Extended-range automobile fuel evaporation emission control system

A technology of evaporative emission and control system, which is applied to vehicle components, arrangement combined with internal combustion engine fuel supply, containers, etc., can solve problems such as wasting resources and polluting the environment, and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

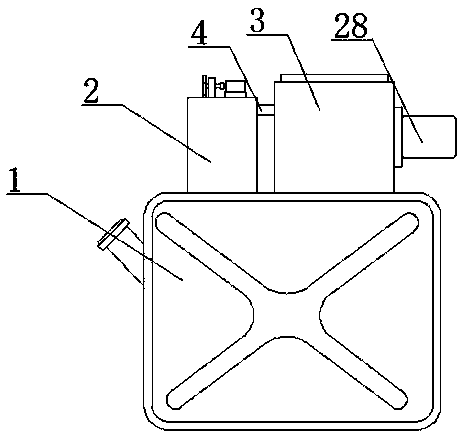

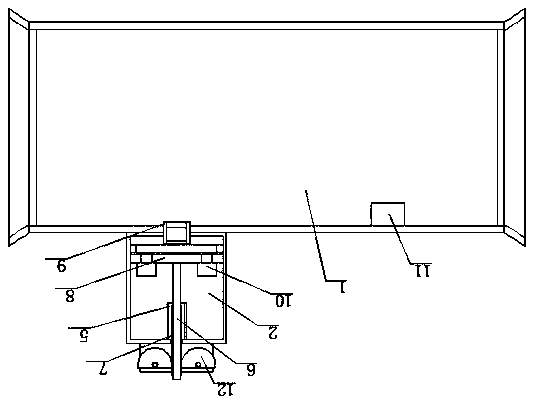

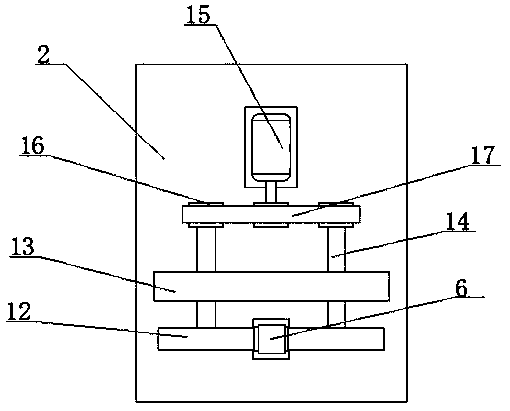

[0027] refer to Figure 1-6 In this embodiment, an extended-range vehicle fuel evaporative emission control system is proposed, including a fuel tank 1, a pressure sensor 11, a controller and a frequency converter. The pressure sensor 11 is fixedly installed in the fuel tank 1, and the controller is connected with the pressure sensor and the The inverter is electrically connected, the top of the oil tank 1 is fixedly installed with the connection box 2 and the storage box 3, and the inner wall of the top side of the connection box 2 is sealed and fixed with the air pipe 4, and one end of the air pipe 4 extends into the storage box 3 And it is sealed and fixedly connected with one side inner wall of the placement box 3, a sealing cover 5 is fixedly installed on the top inner wall of the connection box 2, and a push rod 6 is sealed and slidably connected on the bottom inner wall of the sealing cover 5, and the bottom end of the push rod 6 extends to A sealing plate 8 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com