Preparation method of silver tungsten contact material

A contact material, silver-tungsten technology, which is applied in the field of preparation of silver-tungsten contact materials, can solve problems such as affecting the health of production operators, unfavorable social sustainable development, sewage treatment environment, etc., and achieves high resistance to arc burning. , high density, the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

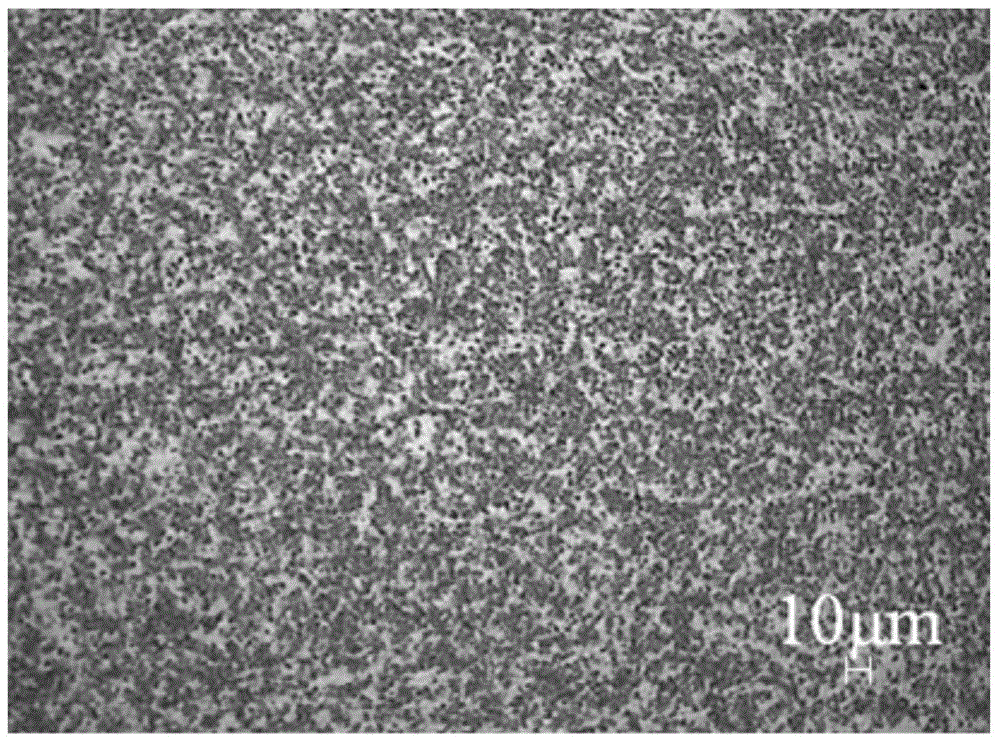

Image

Examples

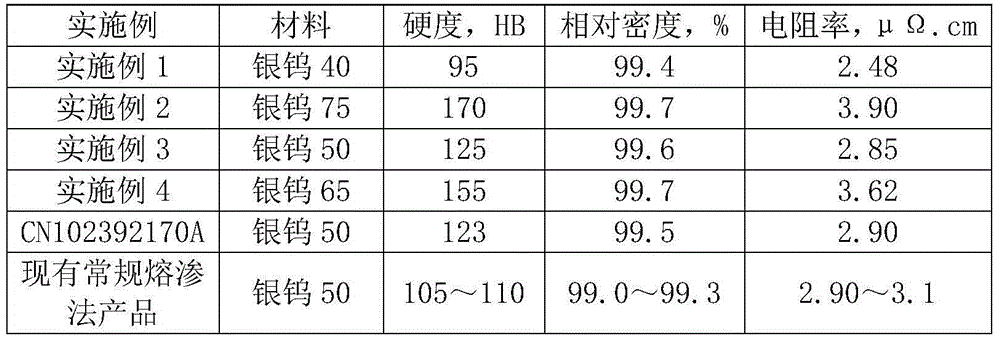

Embodiment 1

[0028] Select tungsten powder with an average particle size of 1 μm and -200 mesh silver powder, weigh 20kg of silver tungsten powder with a total weight of 20kg according to the weight ratio of tungsten: silver = 50:50, put the powder into a 30-liter V-shaped mixer and mix for 2.5 hours Put the mixed silver-tungsten powder, 200kg φ 30mm high-purity nickel balls (nickel content is 99.99%), and 4000ml deionized water together into 100 liters of roller mills and carry out ball milling (rotating speed is 45 rev / min), ball milling time is After 50 hours, take out the powder and dry it at 150°C for 2 hours, place the dried powder in a hydrogen atmosphere and anneal at 850°C for 3 hours (after testing, the nickel content in the obtained powder material is ?0.96%), use 2T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact and the silver sheet in a graphite boat according to the structure of the silver sheet on the bottom of the compact, and infiltrate i...

Embodiment 2

[0030] Select tungsten powder with an average particle size of 9 μm and -100 mesh silver powder, weigh silver tungsten powder with a total weight of 20 kg according to the weight ratio of tungsten: silver = 96:4, put the powder into a 30-liter V-shaped mixer and mix for 2 hours. Combine the mixed silver tungsten powder, 80kg of φ6~φ30mm high-purity nickel balls (with a nickel content of 99.9%) (the weight ratio is φ6mm:φ10mm:φ20mm:φ30mm=3:5:1:1), and 2400ml of deionized water Put it into a 50-liter roller ball mill for ball milling (rotating speed: 50 rpm), the ball milling time is 12 hours, take out the powder and dry it at 80°C for 4 hours, and place the dried powder in an ammonia decomposition gas atmosphere at 700°C Lower annealing for 1 hour (after testing, the nickel content in the obtained powder material is 0.15%), with 4T / cm 2 The annealed powder is pressed into a green compact in a steel mold, and the green compact and the silver sheet are placed in a graphite boat a...

Embodiment 3

[0032]Select tungsten powder with an average particle size of 2 μm and -200 mesh silver powder, weigh silver tungsten powder with a total weight of 20kg according to the weight ratio of tungsten: silver = 70:30, put the powder into a 30-liter V-shaped mixer and mix for 3 hours, Put the mixed silver-tungsten powder, 120kg of φ20mm high-purity nickel balls (nickel content is 99.9%), and 3000ml of deionized water together into a 100-liter roller mill for ball milling (rotating speed is 45 rpm), and the ball milling time is 30 hours , take out the powder and dry at 100°C for 2 hours, place the dried powder in an ammonia decomposition gas atmosphere and anneal at 800°C for 2 hours (the nickel content in the obtained powder material is 0.60% after testing), use 2.5T / cm 2 Press the annealed powder into a compact in a steel mold, place the compact and the silver sheet in a graphite boat according to the structure of the silver sheet on the bottom of the compact, and infiltrate it at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com