Industrial ejection device

A jacking device, an industrial technology, applied in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve problems such as unadjustable position of ejector pin, failure of ejector pin to eject workpiece, and inability to adjust ejection position, etc. , to achieve the effect of reducing friction and increasing installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

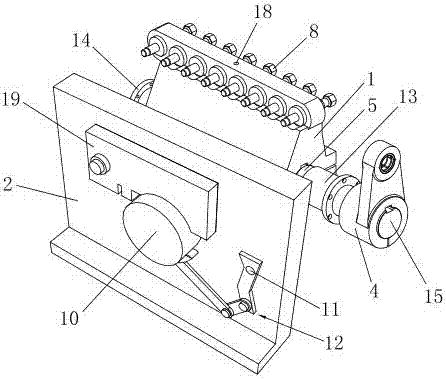

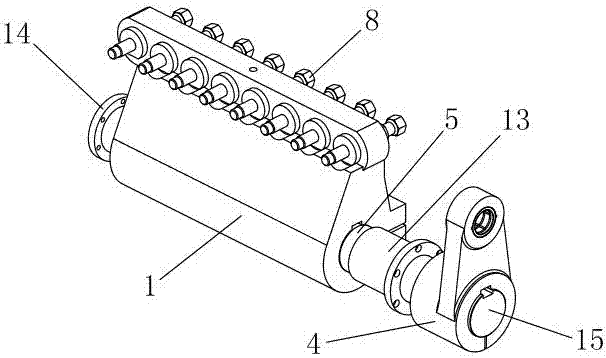

[0024] Such as Figure 1 to Figure 5 As shown, it is an industrial ejecting device of the present invention, which includes a back impact impact seat 1 and an adjustment seat 2. The adjustment seat 2 is L-shaped, and can control the height of the adjustment seat 2 as a whole according to the position of the ejected workpiece. To fix the adjustment seat 2 on the whole machine, U-shaped blocks can be appropriately added, and the U-shaped blocks clamp the two sides of the adjustment seat 2 to increase the stability of the adjustment seat 2. The adjustment base 2 is provided with a support platform 3, and the rear impact impact base 1 is movably connected to the support platform 3, and generally the rear impact impact base 1 is movably connected to the support platform 3 through a movable slider.

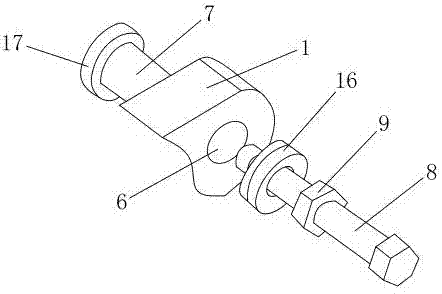

[0025] One side of the back impact base 1 is provided with a single-arm rocker 4, and the single-arm rocker 4 is connected with a rear racket shaft 5, and the rear racket shaft 5 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com