Sorting grid and powder selecting machine for sorting by sorting grid

A powder classifier and sorting technology, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, can solve the problem of material agglomeration, full dispersion of lumpy materials, and influence on sorting Efficiency and cleaning rate and other issues, to achieve a good effect of breaking up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

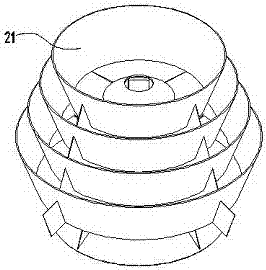

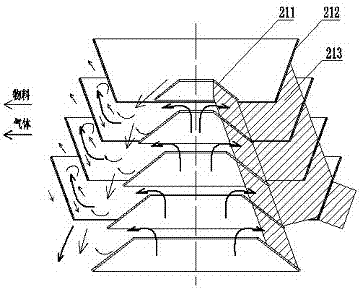

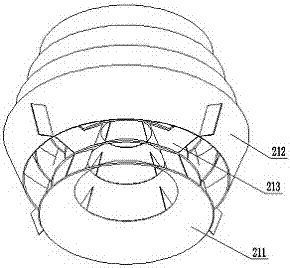

[0049] A sorting grid 21 of this embodiment. The sorting grid 21 includes a plurality of inverted frustum-shaped outer grid plates 212, a plurality of forward frustum-shaped inner grid plates 211, and a plurality of grid plates 213. The selection grid 21, the outer grid plate 212 and the inner grid plate 211 are coaxially sleeved along the central axis of the sorting grid 21, and a plurality of the outer grid plates 212 and the inner grid plates 211 are arranged in a radial direction. The grid plates 213 are connected from top to bottom to form a whole and form an air duct for air to pass through and a dispersing and sorting channel for materials to fall step by step.

[0050] Such as figure 1 , image 3 As shown, the inner ring of the sorting grid 21 is the inner grid plate 211 arranged step by step along the axis, and the outer ring is the outer grid plate 212 arranged step by step along the axis. The inner grid plate 211 and the outer grid plate 212 pass through the partition ...

Embodiment 2

[0056] A sorting grid 21, such as figure 1 , figure 2 , image 3 As shown, the sorting grid 21 includes at least one inner grid plate 211 that is a rounded truncated platform with a small top and a large bottom, at least one outer grid plate 212 that is a rounded truncated platform with a large top and a small bottom, and at least one is connected to the inner grid at the same time. 211 and the grid plate 213 of the outer grid plate 212, the inner grid plate 211 located in the inner ring and the outer grid plate 212 located in the outer ring are coaxially arranged along the center axis of the sorting grid 21 and connected into a whole by the grid plate 213, At the same time, the inner grid plate 211 and the outer grid plate 212, which are both thin-walled pieces, form an air channel for the gas to quickly pass through and a sorting channel for the material to drop and disperse step by step.

[0057] The number of the inner grid plate 211 and the outer grid plate 212 is multiple (...

Embodiment 3

[0063] Such as Figure 4 to Figure 8 As shown, a powder classifier using a sorting grid 21 for sorting includes a shell 1 welded with a fixed foundation 001 on the outside and a material sorting cavity set inside, and powder sorting installed on the shell 1 respectively Mechanism, feeding mechanism 3, discharging mechanism; the housing 1 is provided with an air inlet 11, an air outlet 12, a material inlet 13, and a material outlet communicating the inside and outside of the housing 1, and the air inlet 11 is located below the air outlet 12 , The feeding device is connected to the feeding port 13 and the feeding end of the powder selecting mechanism, while the discharging device is connected to the discharging port and the discharging end of the powder selecting mechanism. The powder selecting mechanism includes a sorting device for one-stage sorting. The grid 21 and the feeding end of the sorting grid 21 at the top are connected with the feeding device. Such as Figure 5 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com