Fan-shaped air suction nozzle capable of automatically adjusting air suction speed

A technology of automatic adjustment and speed, applied in the direction of injection device, liquid injection device, etc., can solve the problems of limited mixing efficiency, inability to adjust the air intake speed, and inability to guarantee the air intake speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

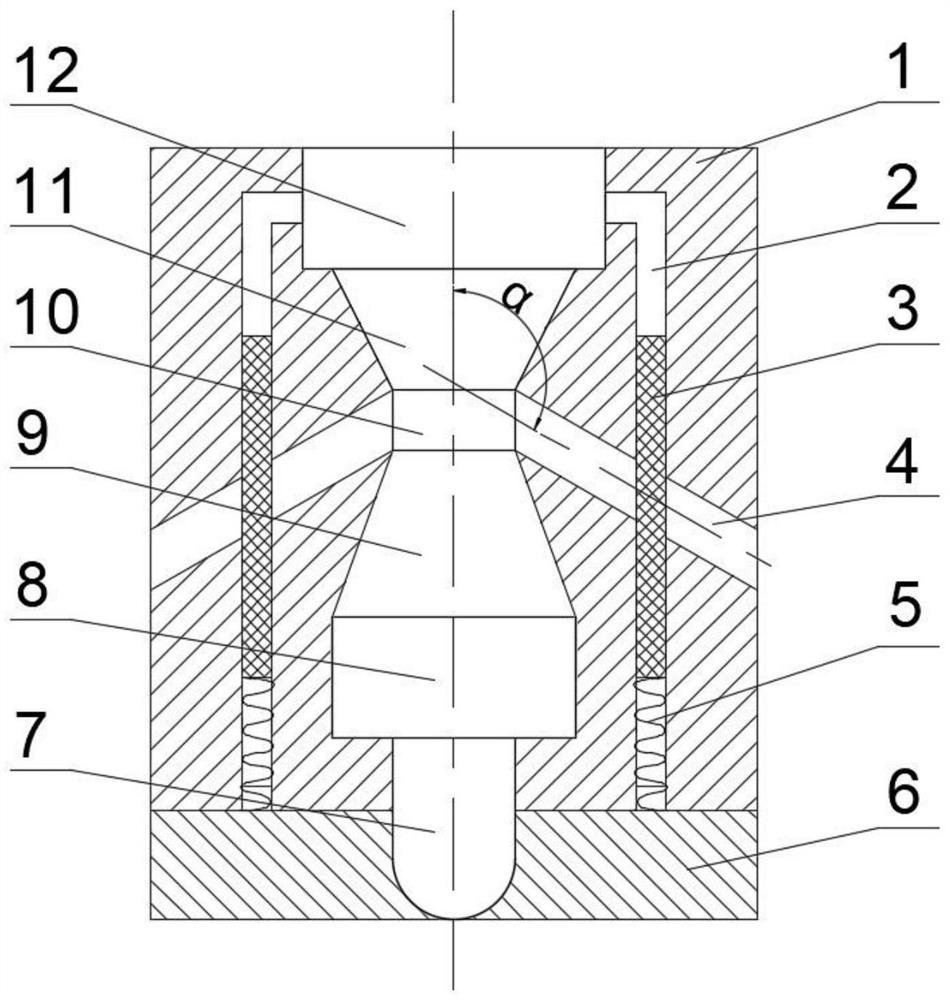

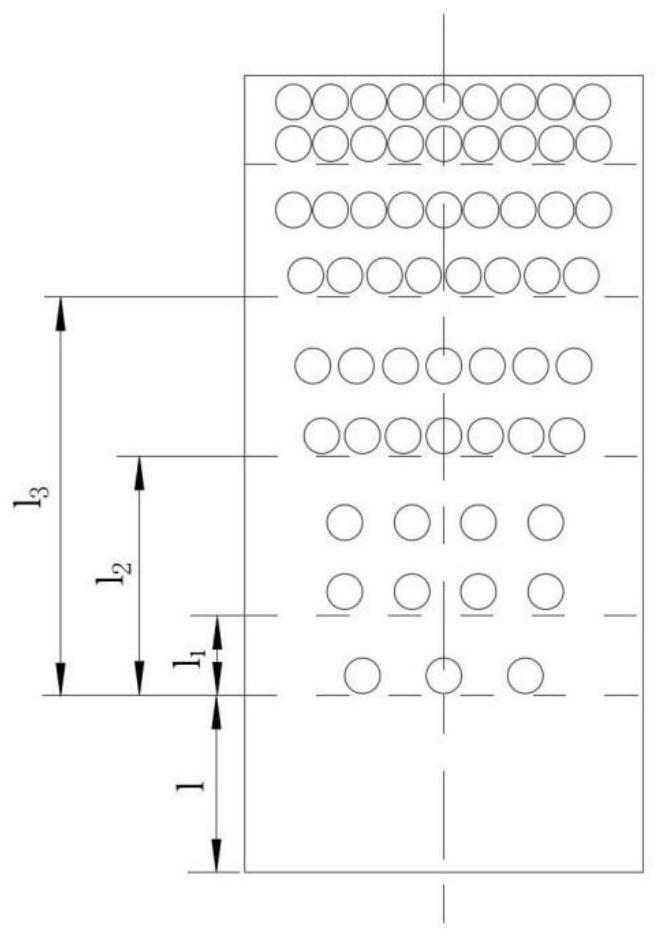

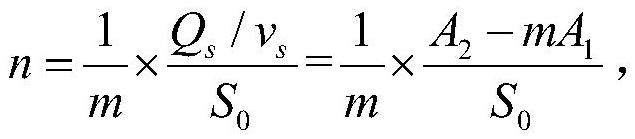

[0075] According to the research results of the existing air-suction nozzles, when a fan-shaped air-suction nozzle that can automatically adjust the air intake is used in conjunction with the present embodiment, the diameter at the entrance of the tapered section 11 is 6mm, and the diameter at the exit of the tapered section 11 is 6 mm. The diameter and the diameter of the straight column section 6 at the air inlet are 3mm; the air intake channel 4 section is a rectangle with a length of 3mm and a width of 1.5mm; 2mm, the area S of the contact surface between the air inlet orifice plate 3 and the liquid in the pressure tank 2 c is the product of the width and thickness of the air inlet orifice plate 3, that is, S c 9mm 2 ; The diameter of the through hole on the air inlet orifice plate 3 is 0.4mm, i.e. the area of the through hole S 0 0.1256mm 2 ; The spring 5 selects a round wire coil spring with an outer diameter of 2mm, a natural length of 6mm, and an elastic coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com