Modified positive electrode material precursor, preparation method thereof, modified positive electrode material and lithium battery

A cathode material and precursor technology, which is applied in the field of modified cathode material precursors, can solve the problems of poor safety and change in the surface structure of cathode materials, and achieves the effects of uniform size, short reaction time, and improved coating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

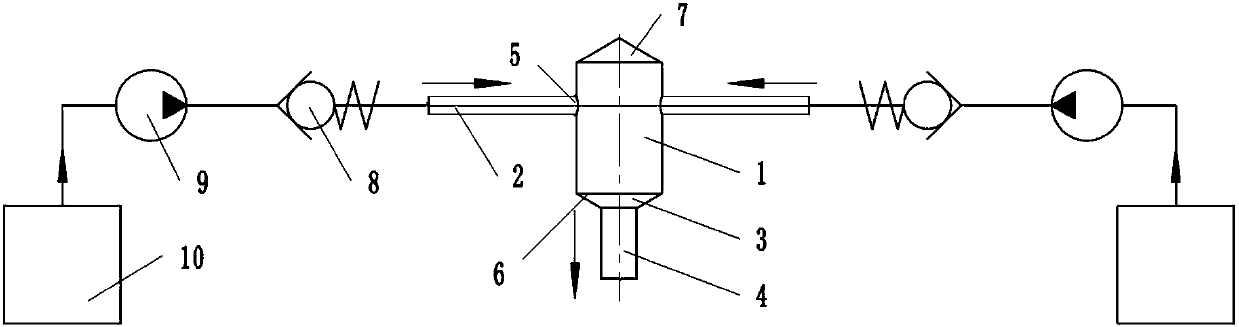

Method used

Image

Examples

Embodiment 1

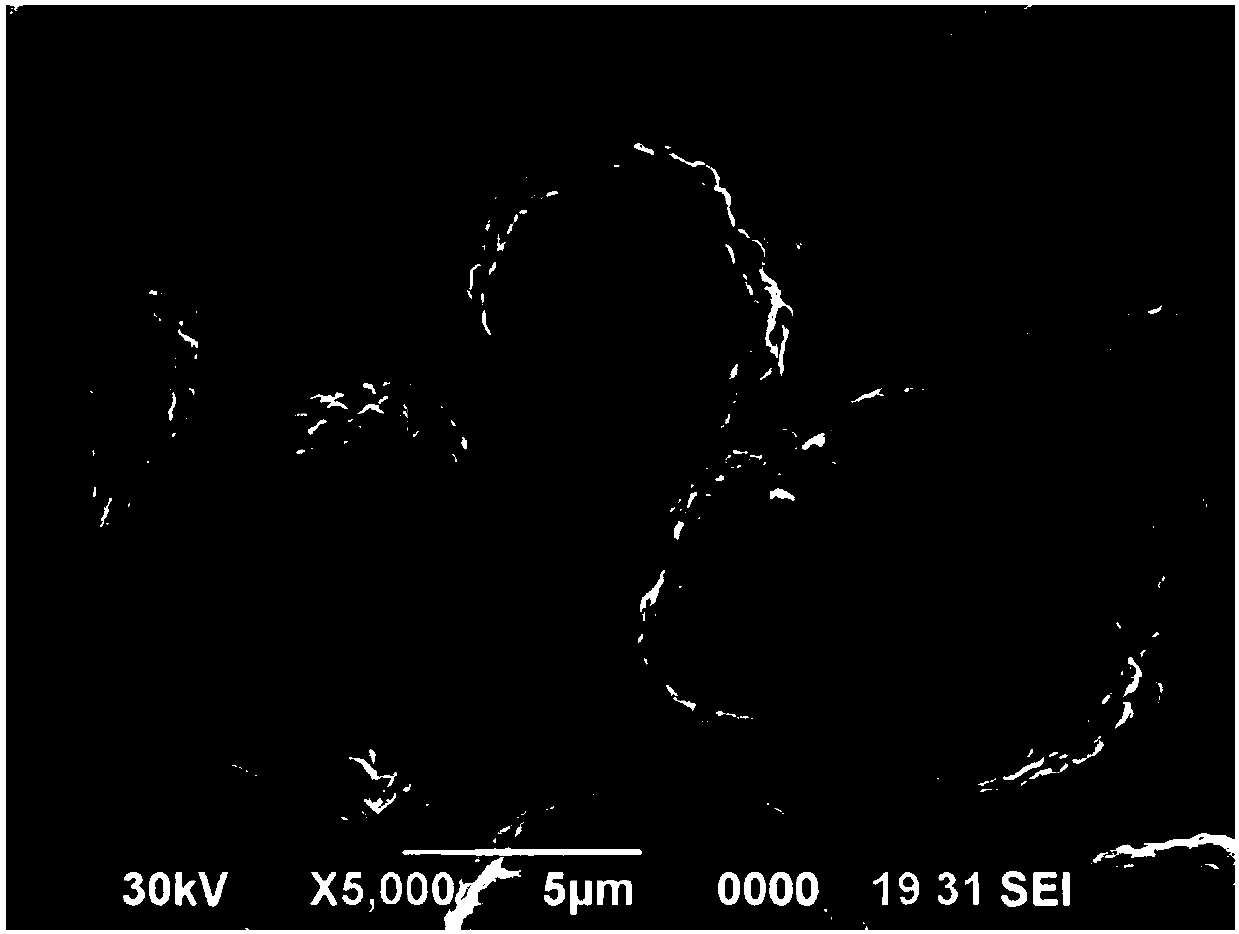

[0113] Preparation of positive electrode material precursor: the positive electrode material precursor Ni with a mass of 32.29g 0.78 co 0.1 mn 0.12 (OH) 2 , 0.92g of diammonium hydrogen phosphate was dissolved in 500g of water to obtain a solution of diammonium hydrogen phosphate, mixed and stirred for 0.5h to obtain mixture A, 1.84g of nickel sulfate was dissolved in 500g of water to form nickel sulfate aqueous solution and mixture A respectively through impinging flow reaction The reactor is reacted, and the mixture A is 23l / h through one end of the feed pipe 2 in the reactor, and the linear velocity is 0.51m / s to enter the impingement flow reaction device, and the nickel sulfate aqueous solution passes through the other end of the feed pipe 2. One end is 20l / h with flow rate, and linear velocity is 0.44m / s and mixture A enters impingement flow reaction device simultaneously and reacts, obtains the positive material precursor (the cathode material precursor of nickel phosp...

Embodiment 2

[0123] The preparation of positive electrode material precursor: the positive electrode material precursor Ni that mass is 32.29g 0.7 co 0.15 mn 0.15 (OH)) 2 , 0.53g of diammonium hydrogen phosphate was dissolved in 250g of water to obtain a solution of diammonium hydrogen phosphate and mixed and stirred for 2h to obtain mixture A, 1.69g of cobalt sulfate was dissolved in 250g of water to form an aqueous solution of cobalt sulfate and mixture A respectively through an impact flow reactor Reaction, the mixture A is 12l / h by one end of the feed pipe 2 in the reactor, and the linear velocity is 0.27m / s to enter the impingement flow reaction device, and the cobalt sulfate aqueous solution passes the other end of the feed pipe 2 to The flow rate is 10l / h, the linear velocity is 0.22m / s, and the mixture A enters the impingement flow reaction device to react at the same time. After the reaction, it is filtered, washed, and dried in an oven at 100°C to obtain a modified cathode mate...

Embodiment 3

[0131] Preparation of positive electrode material precursor: the positive electrode material precursor Ni with a mass of 3235.4g 0.8 co 0.1 mn 0.1 CO 3 , a concentration of 0.05mol / l ammonia mixed to obtain a mixture A, 99.51g Zr (SO 4 ).5H 2 O and 56.88g H 3 BO 3 The aqueous solution mixture (water is 15kg) and mixture A are respectively reacted by impinging flow reactor, and described mixture A is 315.0l / h with flow rate through one end of feed pipe 2 in the reactor, and linear velocity is 0.77m / s enters The impingement flow reaction device, the nickel sulfate aqueous solution passes through the other end of the feed pipe 2 with a flow rate of 300.0l / h and a linear velocity of 0.74m / s and the mixture A enters the impingement flow reaction device at the same time to react. Dry to obtain a modified positive electrode material precursor (zirconium borate-coated positive electrode material precursor). The impingement flow reactor is the same as in Example 1.

[0132] Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com