Vertical multi-stage straw grinder

A straw shredder, vertical technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of limited reuse, high cost of use, troublesome manufacturing, etc., to achieve easy replacement and strong cutting force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

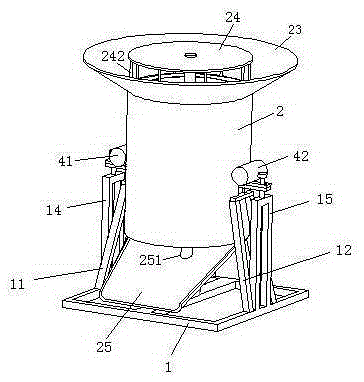

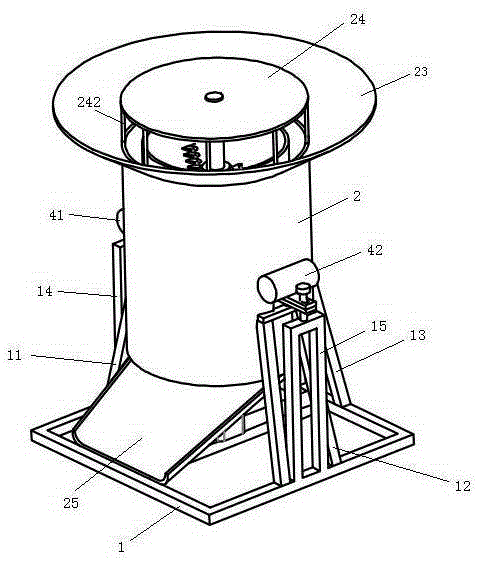

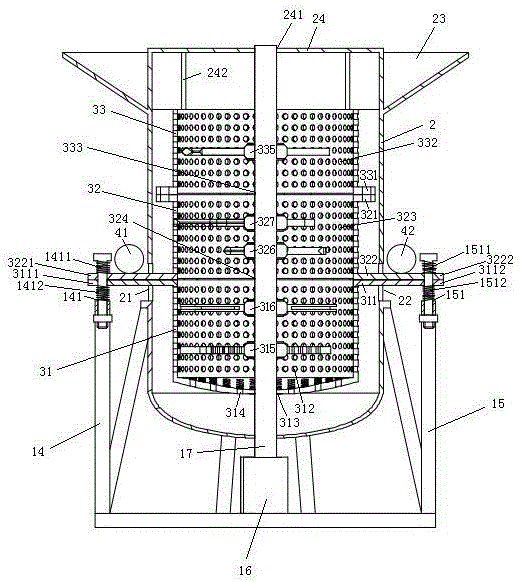

[0032] The vertical multistage straw pulverizer of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] see figure 1 , figure 2 and image 3 , the vertical multi-stage straw pulverizer of the invention comprises a base 1, the base 1 is in the shape of a frame, and the middle of the left frame side, the right frame side and the rear frame side of the base 1 are respectively provided with a The frame-shaped left bracket 11, the right bracket 12 and the rear bracket 13 inclined inwardly, the left frame side and the middle part of the right frame side of the base 1 are respectively provided with a vertical frame-shaped left and right brackets. Right vibrating arm base 14, 15, the middle part of the upper end surface of the left vibrating arm base 14 and the right vibrating arm base 15 in the vertical frame shape are respectively provided with a left vibrating arm bolt hole 141 and a right vibrating arm bolt hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com