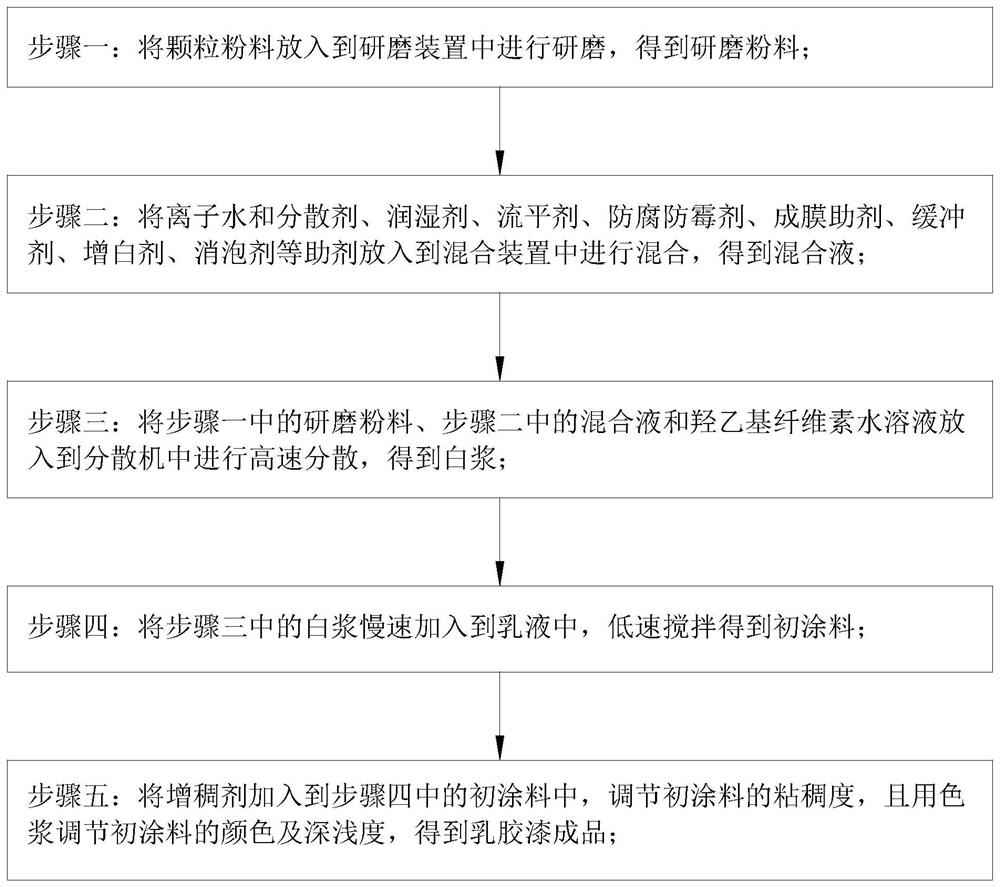

A kind of production method of latex paint

A production method and latex paint technology, applied in cocoa, coatings, powder coatings, etc., can solve the problems of insufficient grinding of water-based paints, inability to work continuously for a long time, unfavorable paint grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

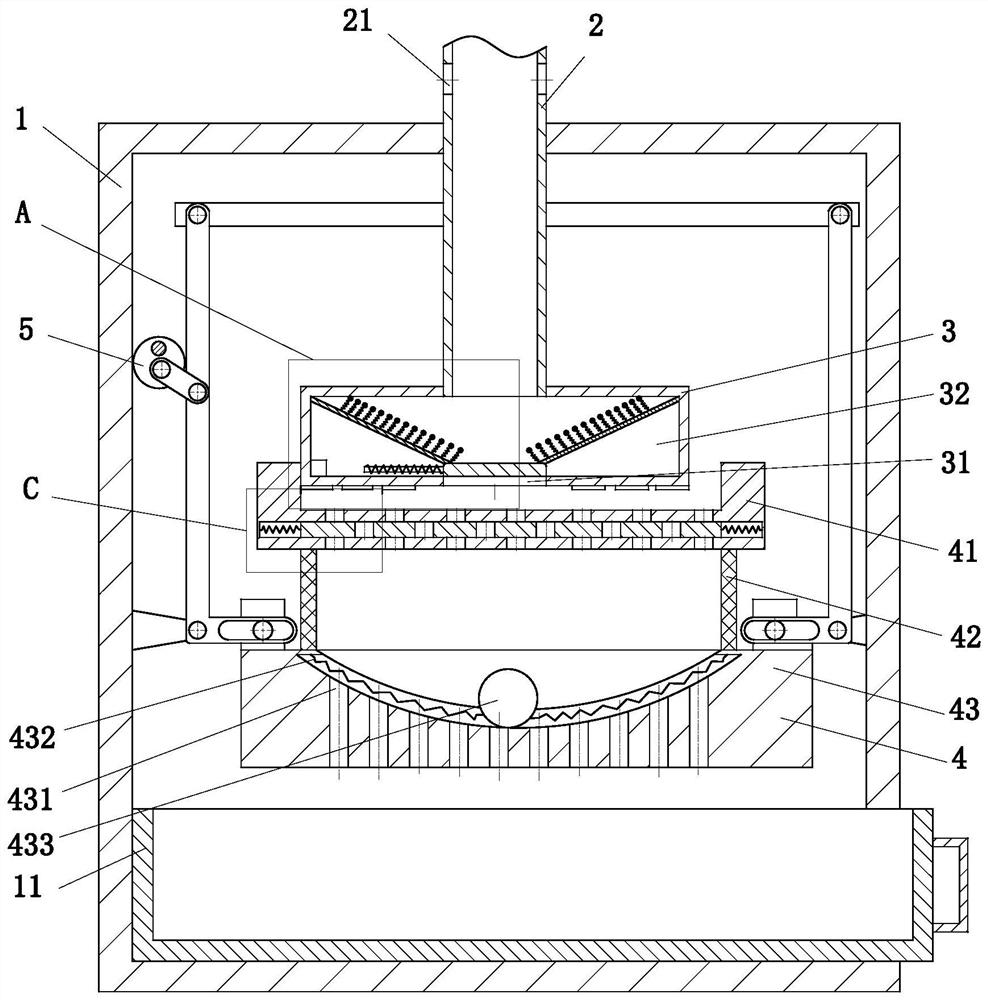

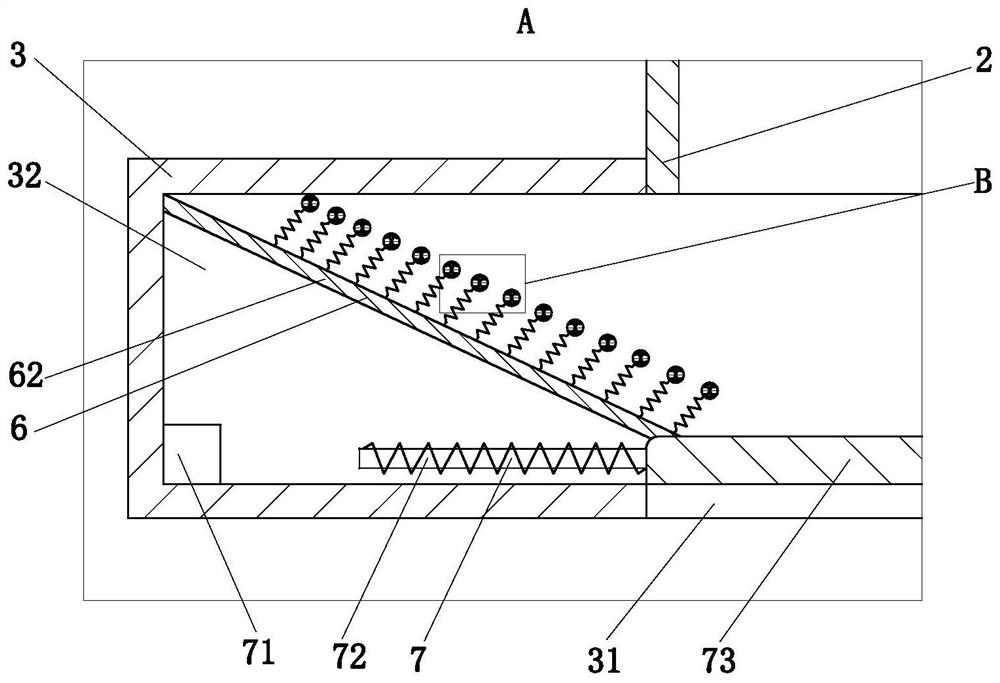

[0043] As an embodiment of the present invention, the upper grinding disc 3 is provided with a hollow chamber 32; the hollow chamber 32 is provided with a crushing unit 6; the crushing unit 6 includes a crushing ball 61 and a fixed plate 62; The fixed plate 62 is symmetrically and obliquely fixed on the inner wall of the upper grinding table 3. The fixed plate 62 divides the hollow chamber 32 into two parts; 62 evenly distributed. There are some large-diameter particles in the water-based paint before grinding. When the water-based paint of the large-diameter particles passes through the grinding of the upper millstone 3 and the lower millstone 4, the water-based paint of the large-diameter particles affects the grinding efficiency; The water-based paint is preliminarily crushed before, and the water-based paint is transported from the feed port to the hollow shaft 2. At the same time, the motor drives the hollow shaft 2 to rotate, so that the crushing ball 61 fixed on the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com