Impact type multifunctional airborne drilling rig

A percussive, multi-functional technology, applied in percussive drilling, reciprocating drilling rigs, drill pipes, etc., can solve the problems of not meeting the production needs of modern mines, high labor intensity of workers, and increased component loss, achieving low noise, Easy control and high impact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

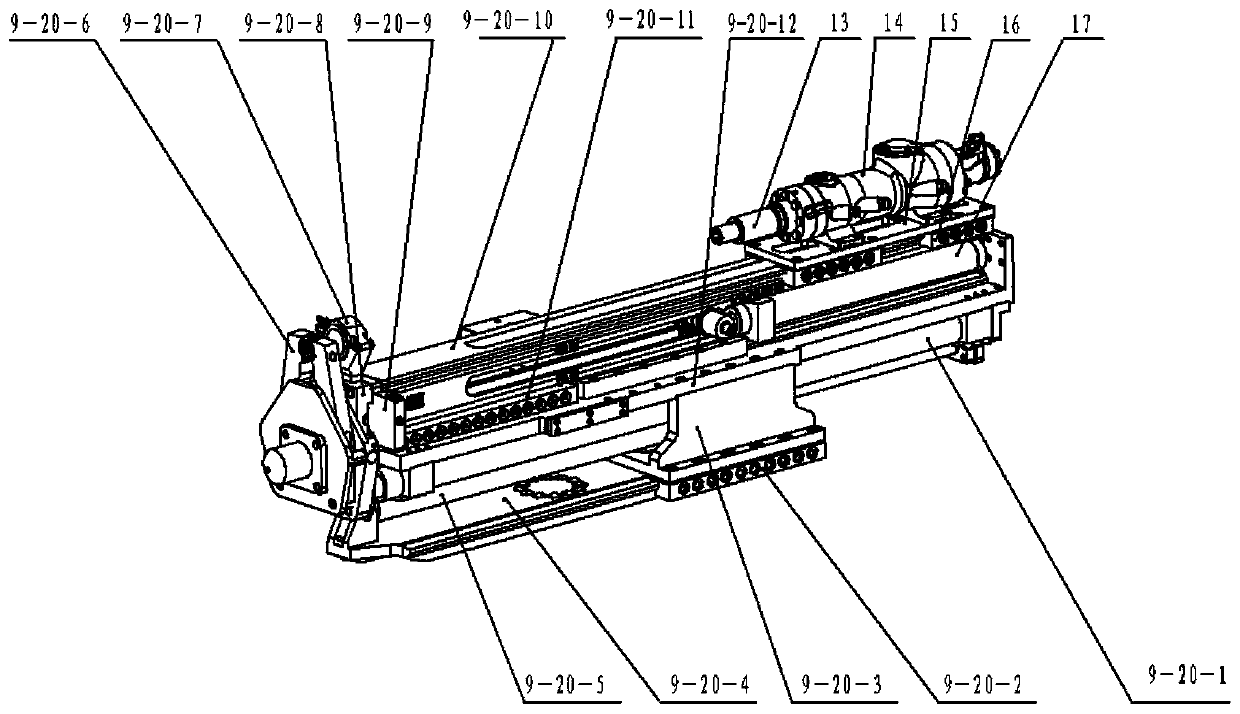

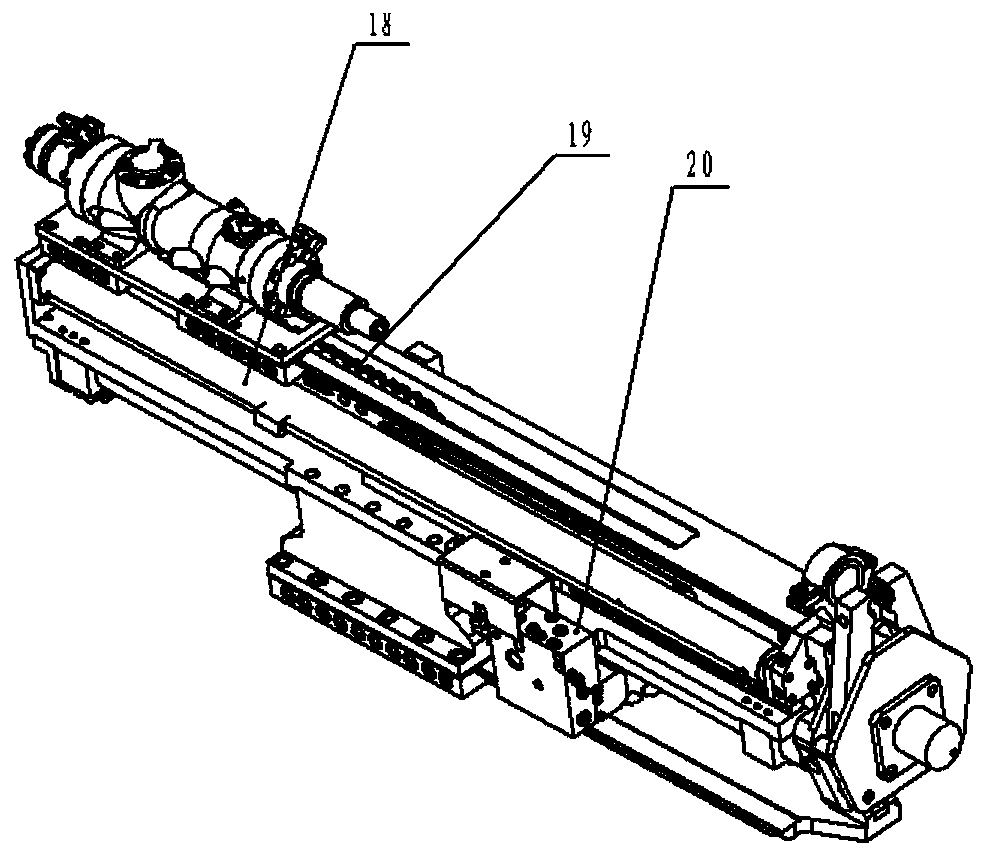

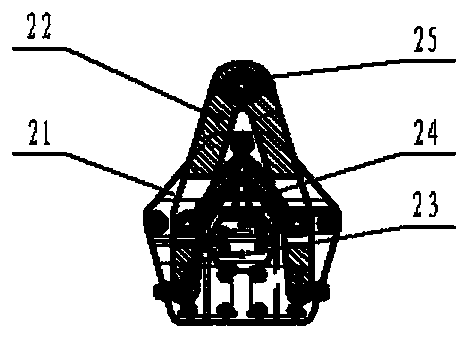

[0020] Such as figure 1 , figure 2 As shown, the percussive multifunctional airborne drilling rig described in this embodiment includes a positioning cylinder 9-20-1, a push slideway pressing block 9-20-2, and a slideway seat 9 -20-3, propulsion slideway 9-20-4, propulsion cylinder 9-20-5, gripper 9-20-6, drill pipe support 9-20-7, drill pipe support seat 9-20- 8. Slideway top plate 9-20-9, slideway 9-20-10, slideway press block 9-20-11, slideway bottom plate 12, forward and reverse large torque transmission device 13, impact rock drilling rig 14, Rock drilling rig fixed plate 15, fixed plate slideway pressure block 16, primary oil cylinder 17, secondary oil cylinder 18, chain assembly 19, integrated valve group 20; the internal installation and positioning of the slideway bottom plate 9-20-12 Oil cylinder 9-20-1 and integrated valve group 20 communicate with each other; one end of positioning oil cylinder 9-20-1 is fixed on the lower end of slideway bottom plate 9-20-12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com