A sealed belt cold and hot shock box

A technology of cold and heat shock and sealing tape, applied in the direction of laboratory appliances, shells or chambers, chemical instruments and methods, etc., can solve the problems of reduced life, low impact efficiency, insufficient energy storage, etc., to eliminate collision displacement, Extended service life and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

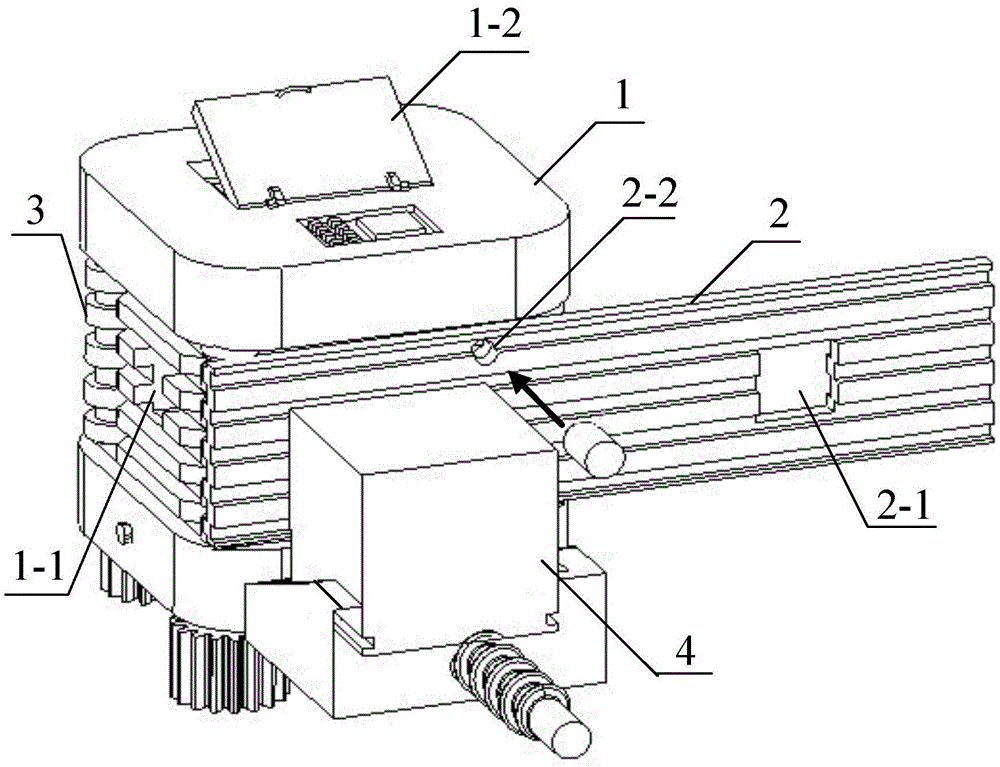

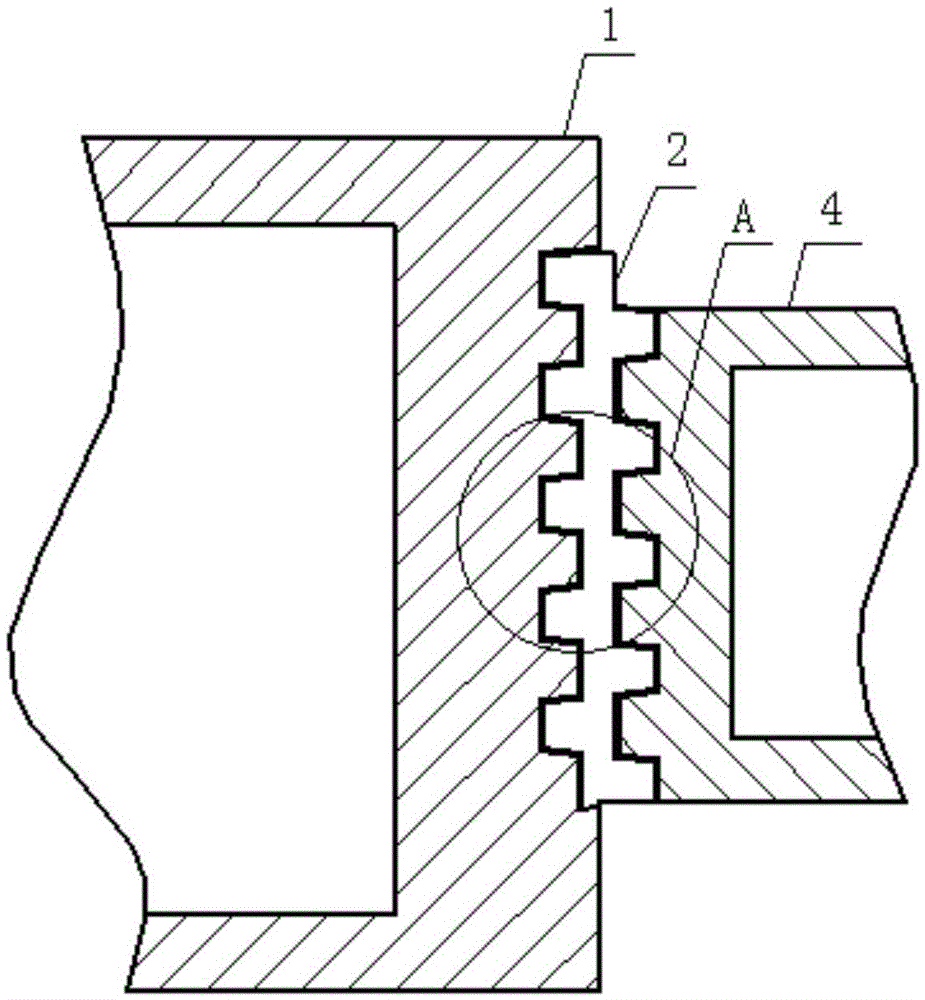

[0028] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a sealing belt type cold and hot impact box described in this embodiment, including a sample box 1, a sealing belt 2, four rotating shafts 3, a motor and four energy storage boxes 4, that is, two heat storage tanks box and two cold storage boxes;

[0029] The sample box 1 is a rectangular parallelepiped structure, and a vent 1-1 is respectively opened on the four side walls of the sample case 1, and the size and height of the four vents 1-1 are the same, and the four rotating shafts 3 are respectively It is fixed at the positions of the four edges on the side of the sample box 1. The sealing tape 2 is set on the four rotating shafts 3 and surrounds the four side walls of the sample box 1. On the outside of the sealing tape 2, it is connected with the four ventilation openings. 1-1 is provided with two heat storage boxes and two cold storage boxes, and the two heat storage boxes ar...

specific Embodiment approach 2

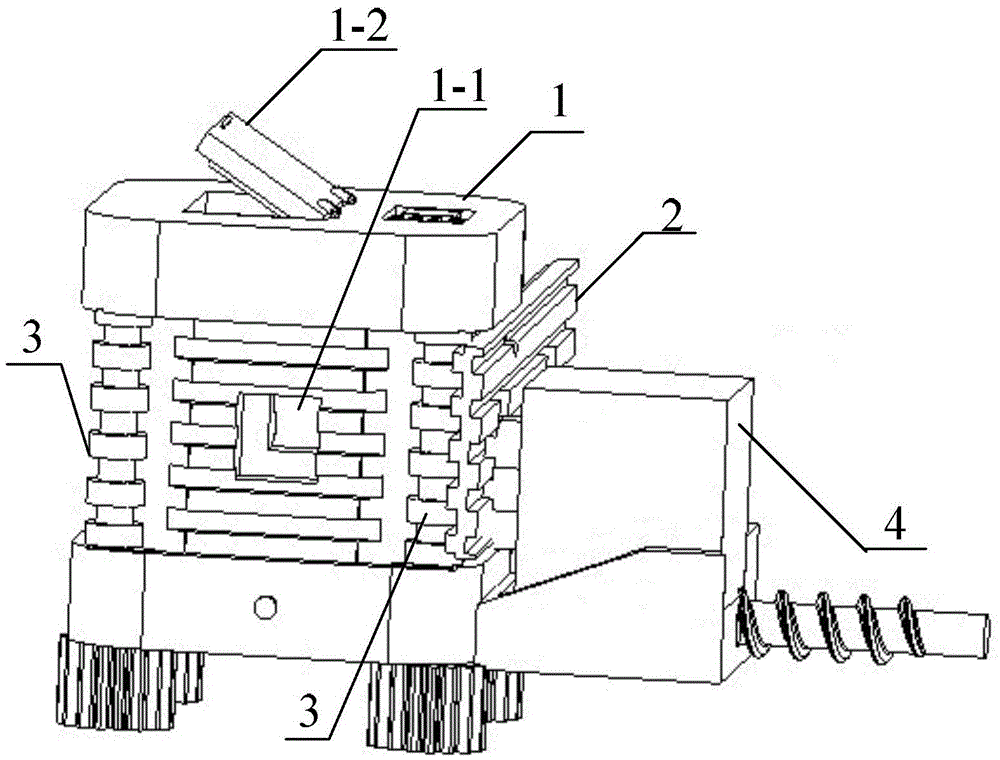

[0044] Specific embodiment 2: This embodiment is a further limitation of the sealed belt type cold and hot shock box described in the specific embodiment. In this embodiment, the cold and hot shock box also includes four photoelectric transmitters, four A photoelectric receiver and a controller, the sealing tape 2 is provided with a light hole 2-2, four photoelectric receivers are evenly distributed around the sample box 1, and the outer surfaces of the four energy storage boxes are respectively equipped with photoelectric transmitters , the photoelectric transmitter is used to emit light signals, the photoelectric receiver is used to receive light signals, and the controller is used to control the start or stop of the motor according to the signals received by the photoelectric receiver.

[0045] This implementation mode increases the control function. The four photoelectric receivers are respectively fixed in the installation grooves on the four side walls of the sample box ...

specific Embodiment approach 3

[0049] Specific embodiment 3: This embodiment is a further limitation of the sealing belt type cold and heat impact box described in the specific embodiment. gas channel.

[0050] When the energy storage box starts to cool (or heat) the sample box 1 or, the blower drives cold gas (or hot gas) into the sample box 1 through the air guide channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com