Movable impact type large pin shaft replacement device and method

An impact device and impact type technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming maintenance operations, long maintenance time, unstable impact force, etc., to save maintenance space resources and save maintenance time and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

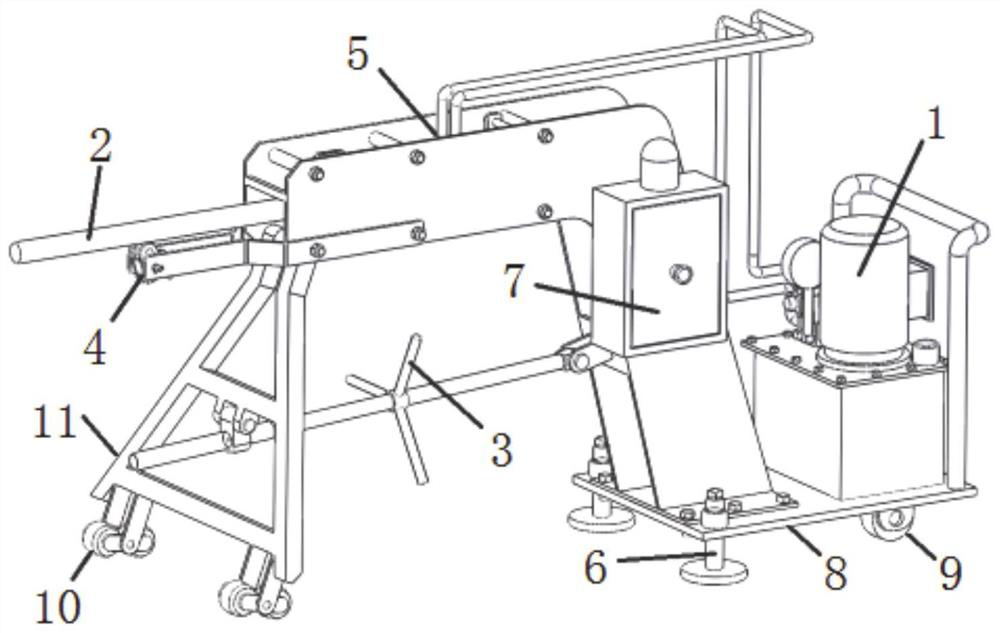

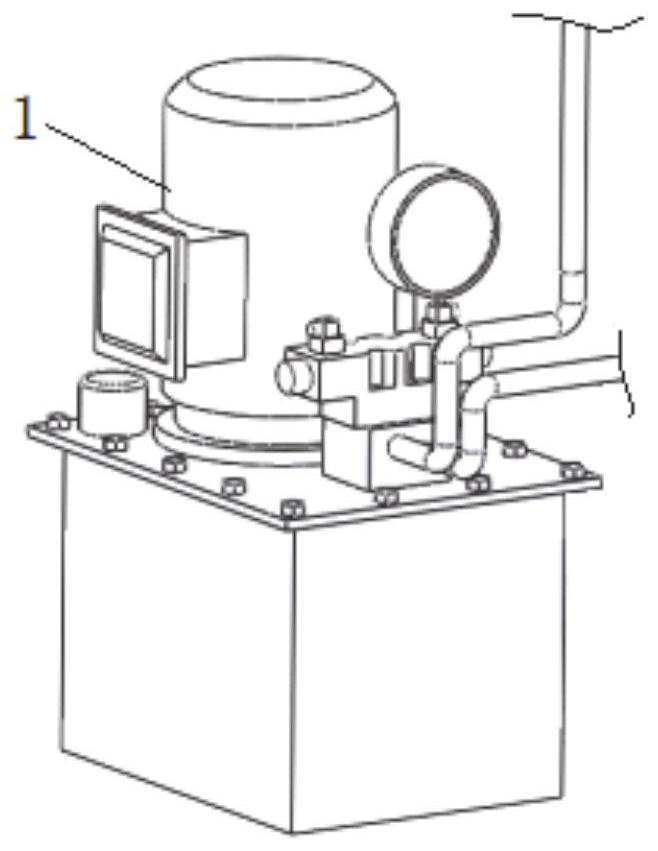

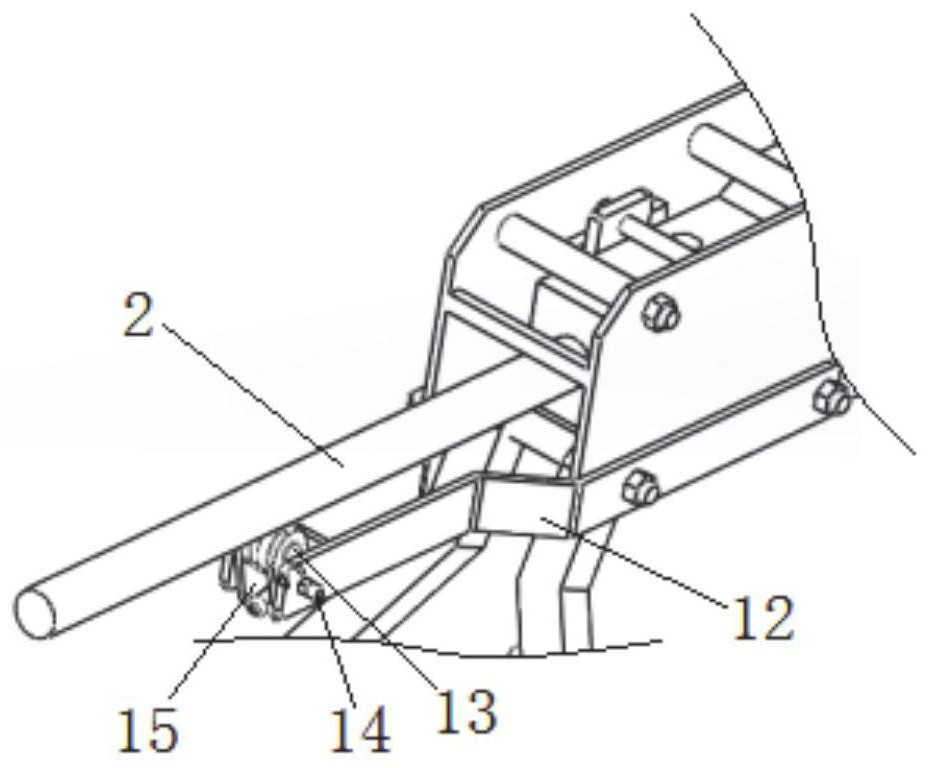

[0033] This embodiment provides a mobile impact type large pin shaft replacement device, wherein the large pin shaft refers to the traction pin connecting the rear axle of the dump truck and the girder; figure 1 As shown, the replacement device includes an impact device body, an adjustment mechanism 3, a fine-tuning mechanism 4, a mobile support assembly, a hydraulic power source 1, and an electrical control box 7. The mobile support assembly is installed at the bottom of the impact device body, and the adjustment mechanism 3 is connected to the impact device. Below the device body, the fine-tuning mechanism 4 is installed on one end of the impact device body.

[0034] An electrical control box 7 is installed on one side of the impact device body, and the impact device body is connected to a hydraulic power source 1 through a pipeline. The electrical control box 7 mainly includes electronic components such as a relay, a current controller, a warning light, an emergency stop bu...

Embodiment 2

[0050] This embodiment provides a mobile impact type large-scale pin replacement method. Using the replacement device described in Embodiment 1, the motor is controlled by the remote controller to rotate to drive the pump station to output hydraulic power, and the power is distributed by controlling the solenoid valve. The mechanism 5 outputs the impact force of the cycle, and the impact moving mechanism 5 transmits the impact force to the impact drill rod 2. After the accurate working position adjustment, the impact drill rod 2 impacts the traction pin, so as to realize the installation or disassembly operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com