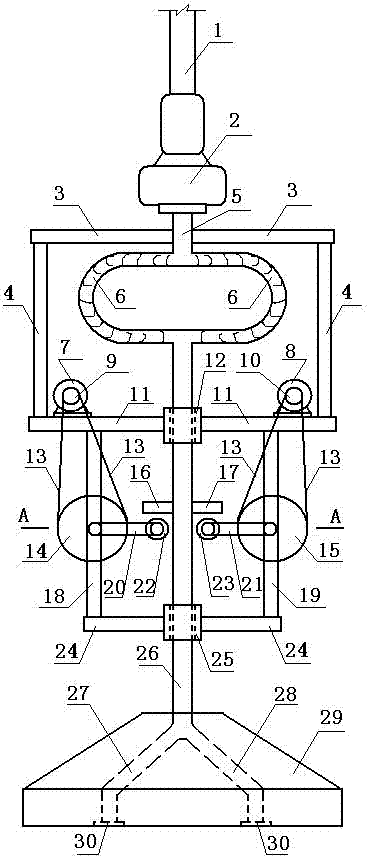

Round Table Hammer Hole Making Machine

A technology of a rotary table hammer and a hole-making machine, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. It can solve the problems of high power consumption and low efficiency, and achieve high impact efficiency and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

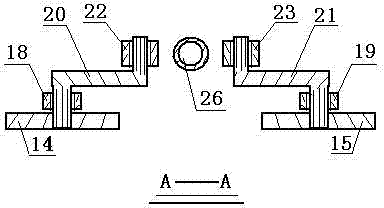

[0012] Accompanying drawing is a kind of concrete embodiment of the present invention, and this embodiment drilling rod 1 lower end is connected with mud pump 2, and mud pump lower end is connected with suction pipe A5, and suction pipe A is fixed in the middle of cross arm A3, cross arm A, cross arm B11, Cross arm C24, two longitudinal arms A4, longitudinal arm B18, and longitudinal arm C19 are welded into a stable steel structure. The lower end of suction pipe A is connected to the upper end of suction pipe B26 through two curved corrugated tubes 6. Suction pipe B passes through sleeve A12, sleeve B25, the lower end of the suction pipe B is connected with the suction pipe C27 and the suction pipe D28, and the lower end of the suction pipe B is also fixed with a round table hammer 29; The end cover is equipped with a wheel A22, the upper part of the wheel A is provided with a handle rod A16, the handle rod A is fixed on the left side of the suction pipe B, and the crank arm B2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com