A high-pressure nano homogenizer

A nano-homogenizer and high-pressure technology, which is used in mixers, dissolving, grain processing, etc., can solve the problems of insufficient refined particle size, failure to reach nano-level, low production efficiency, etc., to achieve low cost and improve production efficiency. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe the present invention in detail below in conjunction with accompanying drawing:

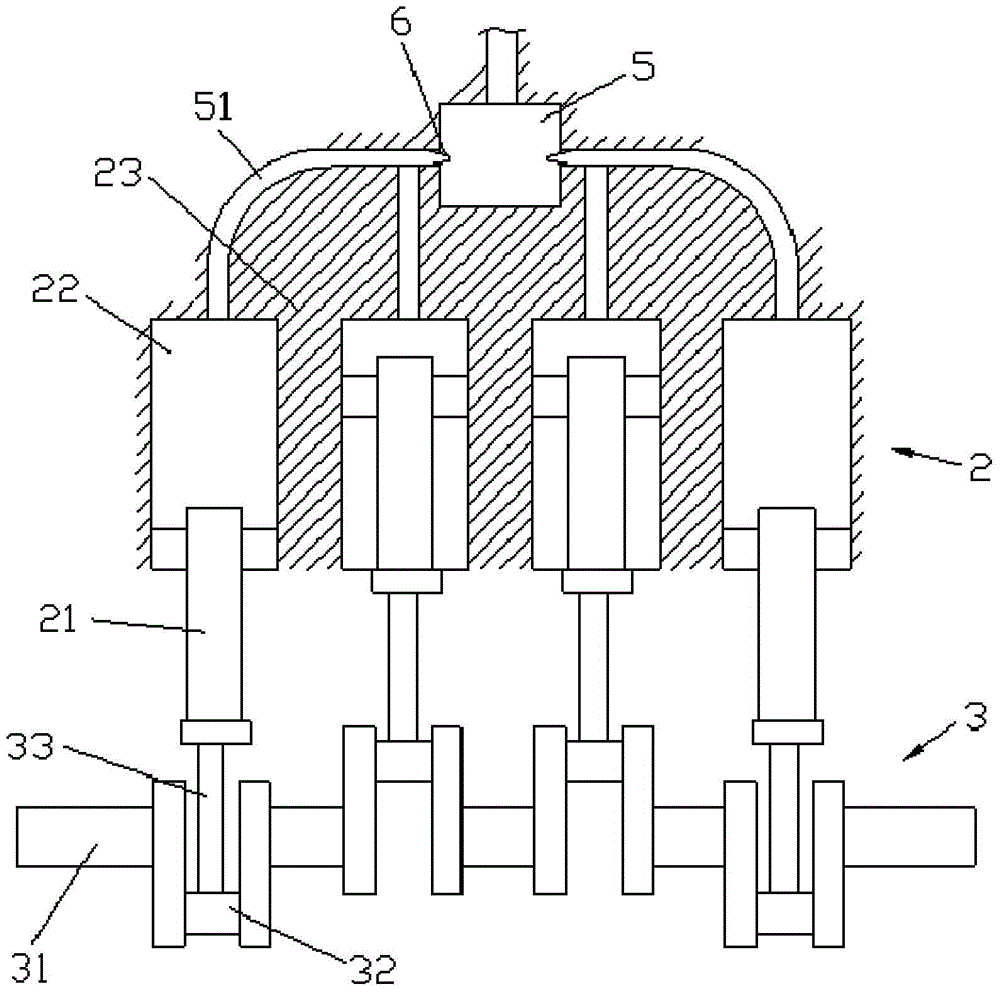

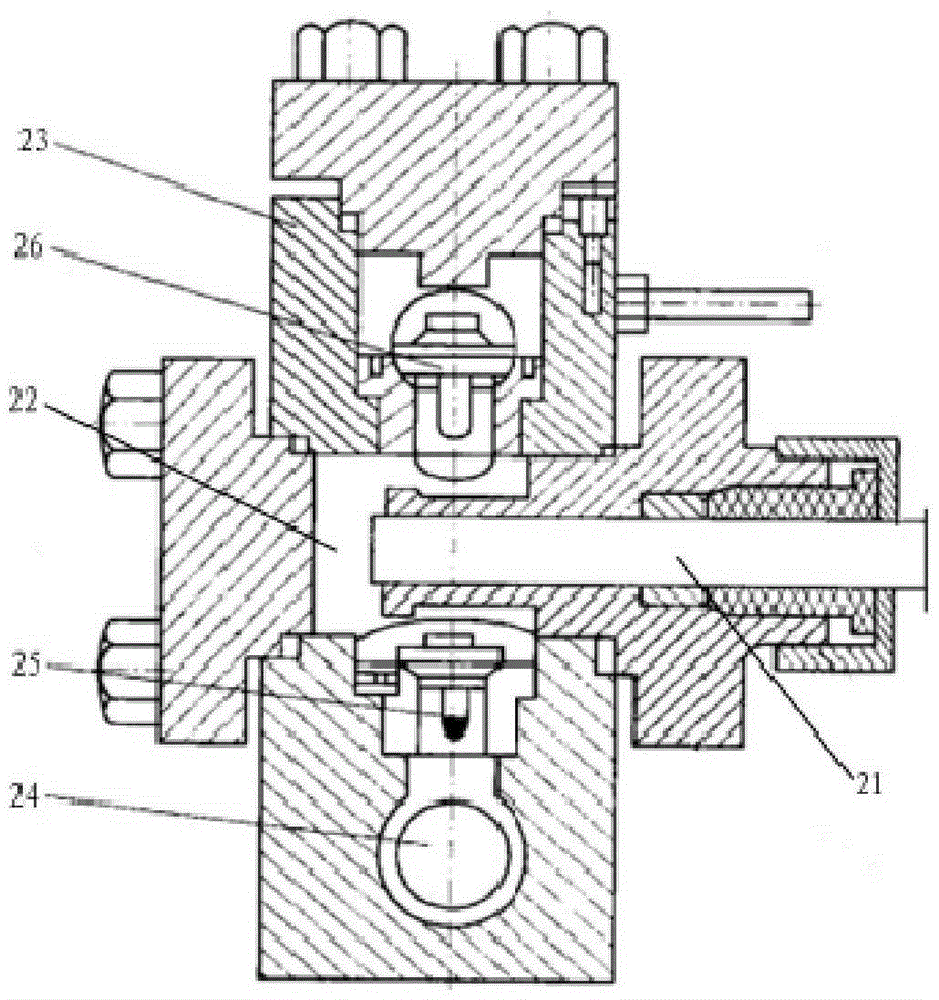

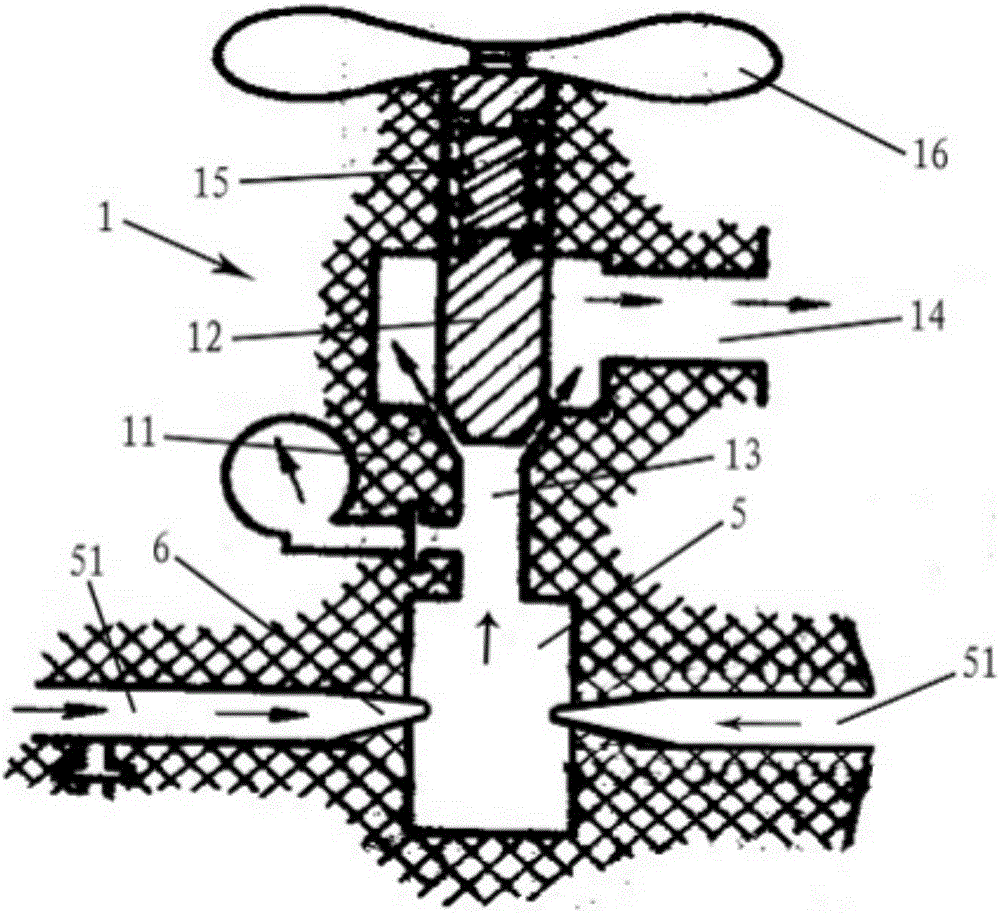

[0019] like figure 1 , figure 2 , image 3 , the nanometer homogenizer (EigerTorrent) of the present invention comprises homogenizing valve 1 and the high-pressure pump 2 of conveying material, and described high-pressure pump 2 comprises at least a pair of plunger 21 driven by transmission mechanism 3, each plunger is arranged on a In the pump chamber 22, each pair of plungers transports the materials in the corresponding two pump chambers to a pair of collision chambers 5 for collision, and the materials after collision flow together to the homogenizing valve. The invention adopts the method of colliding and one-stage homogenization to refine the material, which not only has a simpler structure, but can omit the primary homogenization in the prior art, and the collided material is crushed when it passes through the plane sealing surface of the homogenizing valve. Extrusion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com