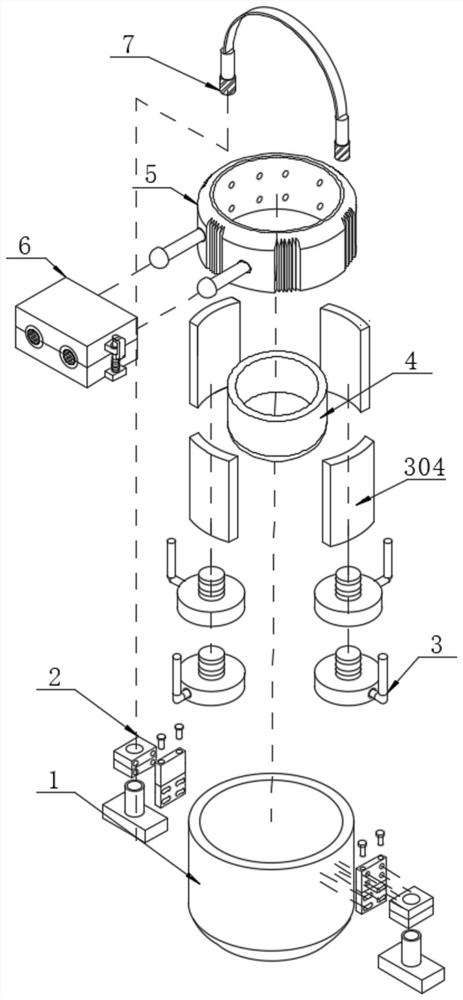

Material flexible freight bag of semicircular special engineering plastic processing equipment

A technology of special engineering plastics and processing equipment, which is applied in the field of container bags, which can solve the problems of rainwater or magazines mixing, breaking, and material scattering, etc., and achieve the effect of satisfying sustainability and high limit bite ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

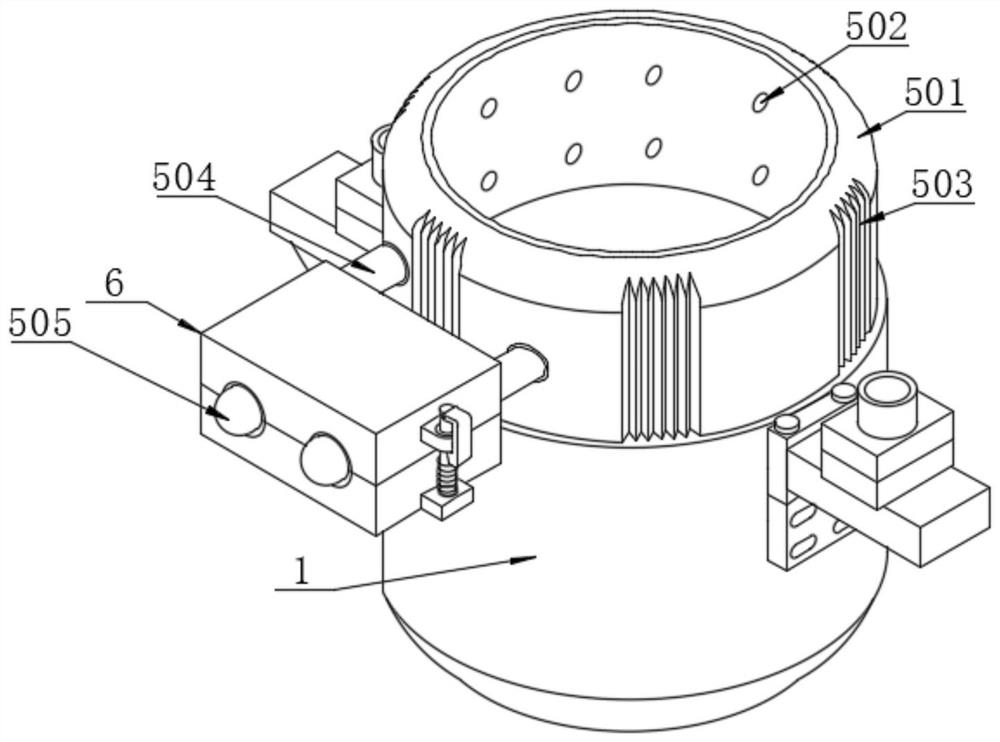

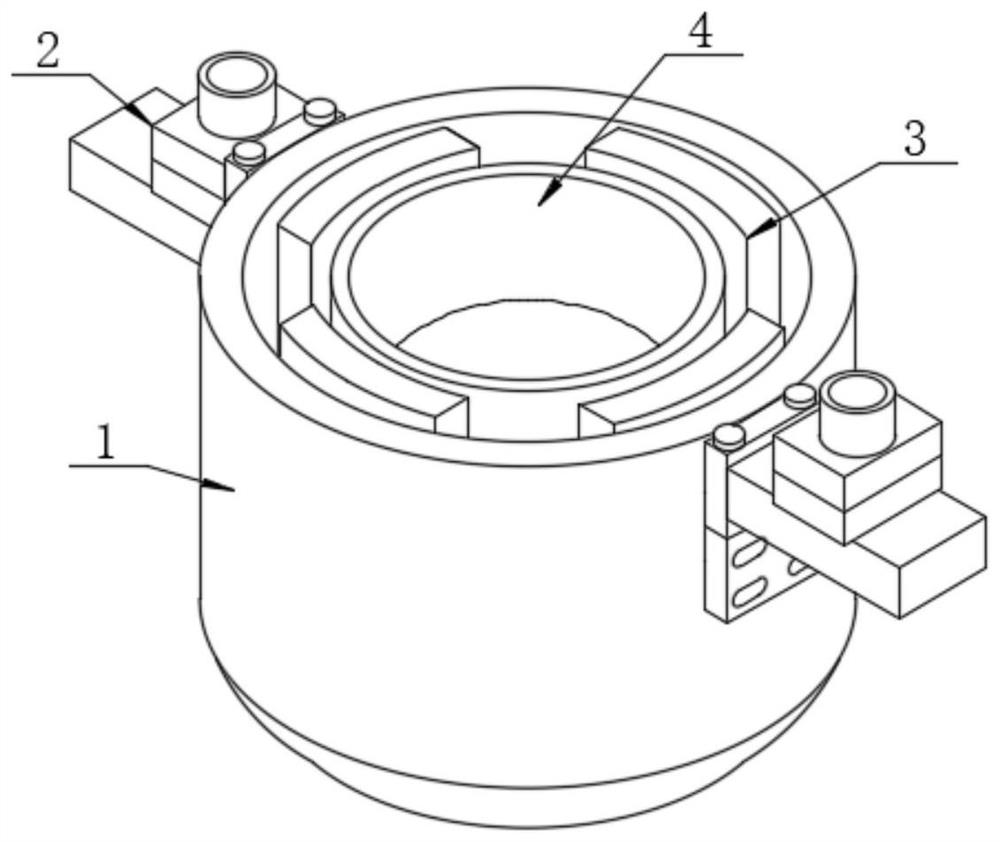

Embodiment approach

[0040]The embodiment is specifically: the elastic cover body 501 is made of rebound type PVC material, which can rebound and expand after shrinkage to achieve a fully closed effect, and the stainless steel twisted thread embedding of the outer bag main body 1 and the inner bag main body 4 can improve the quality of the polypropylene plastic. The tensile strength of the bag can effectively improve the loading capacity of the inner bag main body 4 and the outer bag main body 1, and the through hole 202 on the top of the fixing plate 201 can snap the threaded seat 203, thereby satisfying the requirements for the bottom stop plate 204. The blocking effect, and can meet the connection of the lanyard 7 through modular assembly, and the fixed plate 201 can be connected with the adjustment plate 205 through the installation hole, to meet the needs of horizontal hooking, and the riveting plate 206 is riveted on the outer bag main body 1. It can meet the support strength required by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com