Uniform feeding type proportioning equipment for aquaculture

A technology for aquaculture and batching equipment, applied in application, feed, mixer accessories, etc., can solve the problems of unguaranteed mixing effect, cumbersome control operation, low efficiency, etc., and achieve the effect of convenient and fast control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

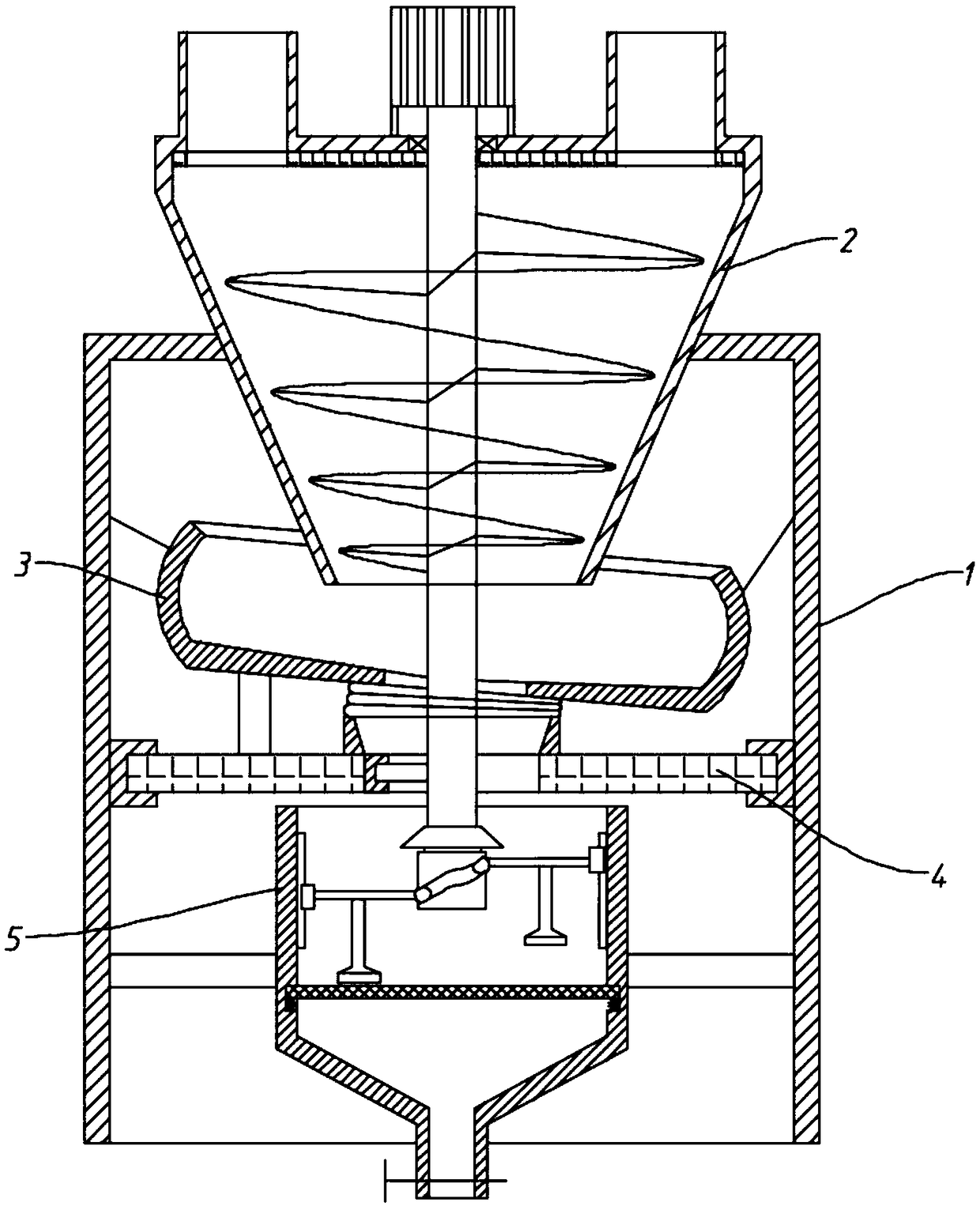

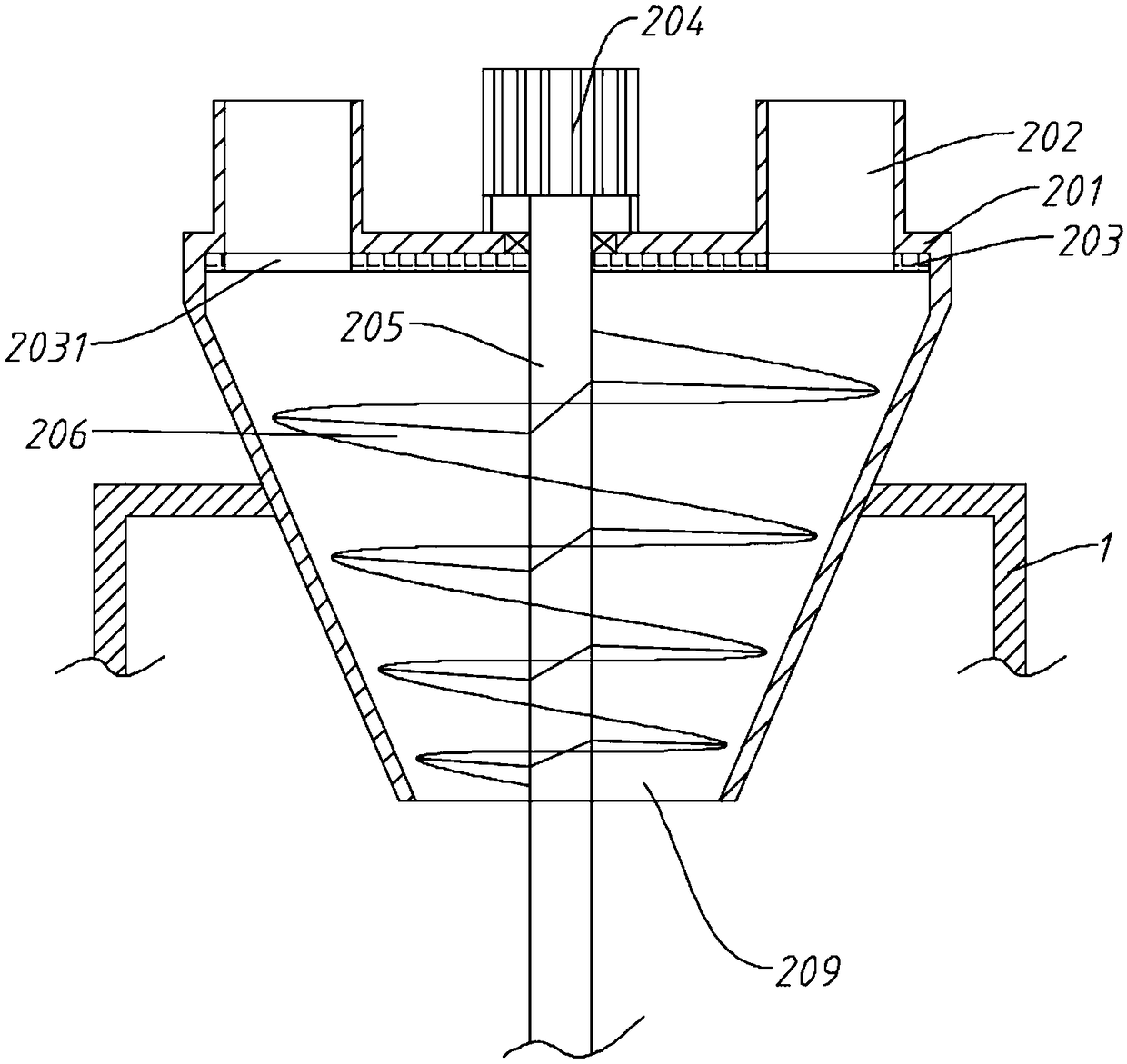

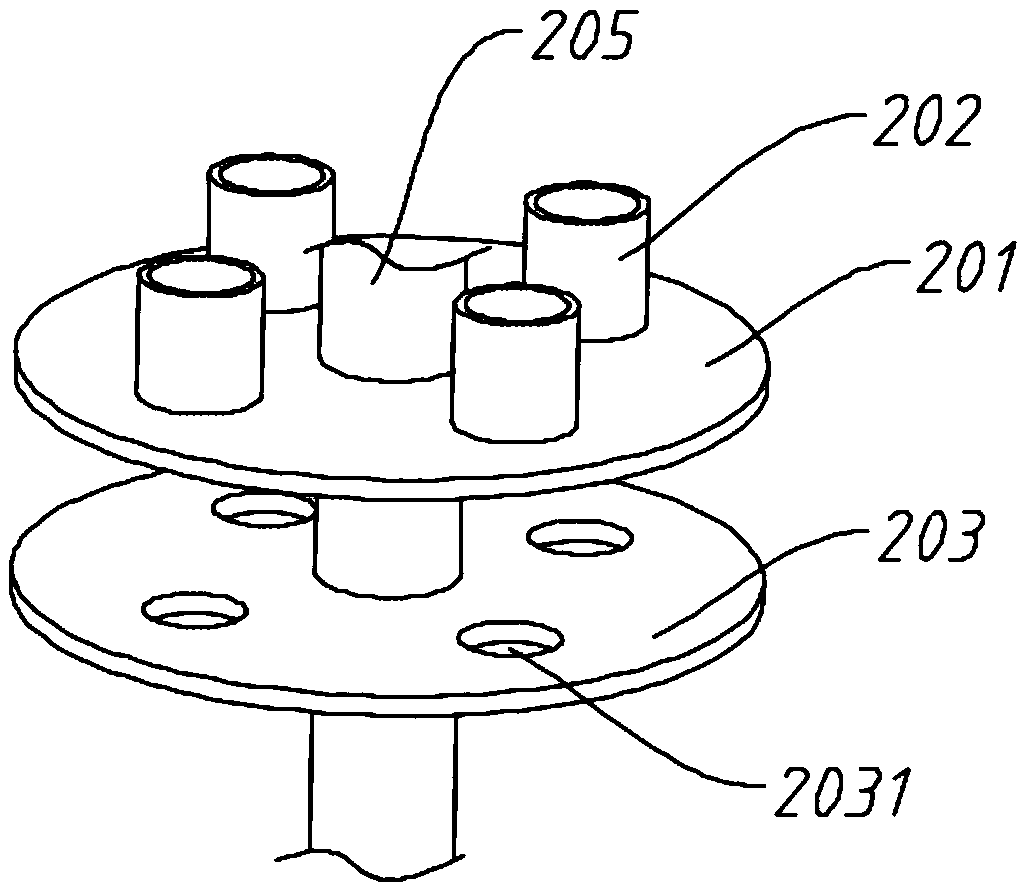

[0038] A uniform feeding type batching equipment for aquaculture, comprising a casing 1 and a mixing barrel 2;

[0039] The mixing barrel 1 is installed on the top of the shell 1, and the bottom end extends into the shell 1; the mixing barrel 2 is a structure with a large top and a small bottom, with a top plate 201 on the top, and a secondary discharge port 209 on the bottom. outlet; the center above the top plate 201 is fixed with a servo motor 204, the output end of the servo motor 204 protrudes downwards and is connected with a rotating shaft 205, and the rotating shaft 205 extends into the mixing barrel 201 and is equipped with a screw auger 205, the screw twist The outer diameter of the dragon 205 is gradually reduced corresponding to the necking structure; the top plate 201 is evenly fixed in the circumferential direction with several discharge cylinders 202, and the bottom of the discharge cylinder 202 also has an outlet; the bottom of the top plate 201 is also provided...

Embodiment 2

[0042] A uniform feeding type batching equipment for aquaculture, comprising a casing 1 and a mixing barrel 2;

[0043] The mixing barrel 1 is installed on the top of the shell 1, and the bottom end extends into the shell 1; the mixing barrel 2 is a structure with a large top and a small bottom, with a top plate 201 on the top, and a secondary discharge port 209 on the bottom. outlet; the center above the top plate 201 is fixed with a servo motor 204, the output end of the servo motor 204 protrudes downwards and is connected with a rotating shaft 205, and the rotating shaft 205 extends into the mixing barrel 201 and is equipped with a screw auger 205, the screw twist The outer diameter of the dragon 205 is gradually reduced corresponding to the necking structure; the top plate 201 is evenly fixed in the circumferential direction with several discharge cylinders 202, and the bottom of the discharge cylinder 202 also has an outlet; the bottom of the top plate 201 is also provided...

Embodiment 3

[0047] A uniform feeding type batching equipment for aquaculture, comprising a casing 1 and a mixing barrel 2;

[0048] The mixing barrel 1 is installed on the top of the shell 1, and the bottom end extends into the shell 1; the mixing barrel 2 is a structure with a large top and a small bottom, with a top plate 201 on the top, and a secondary discharge port 209 on the bottom. outlet; the center above the top plate 201 is fixed with a servo motor 204, the output end of the servo motor 204 protrudes downwards and is connected with a rotating shaft 205, and the rotating shaft 205 extends into the mixing barrel 201 and is equipped with a screw auger 205, the screw twist The outer diameter of the dragon 205 is gradually reduced corresponding to the necking structure; the top plate 201 is evenly fixed in the circumferential direction with several discharge cylinders 202, and the bottom of the discharge cylinder 202 also has an outlet; the bottom of the top plate 201 is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com