Mixing and proportioning device for polyurea waterproof coating production

A waterproof coating, polyurea technology, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve problems such as clogging of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

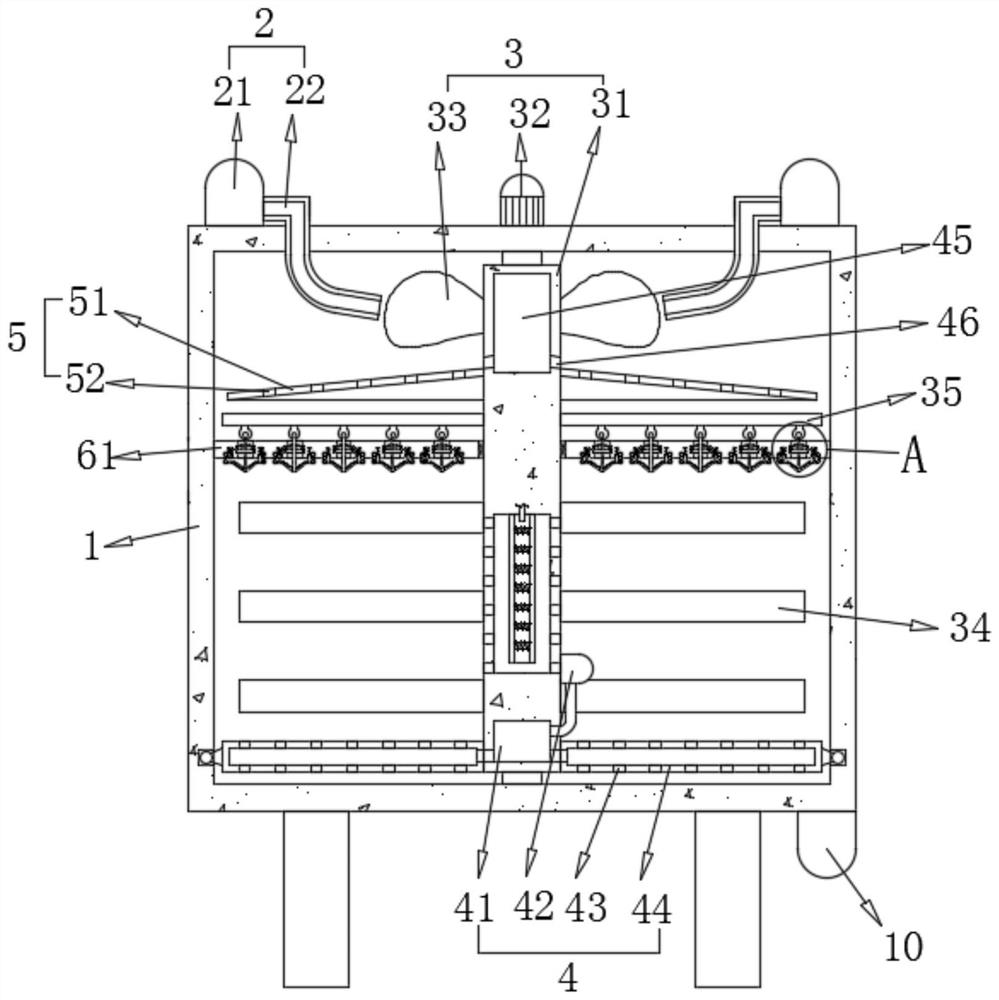

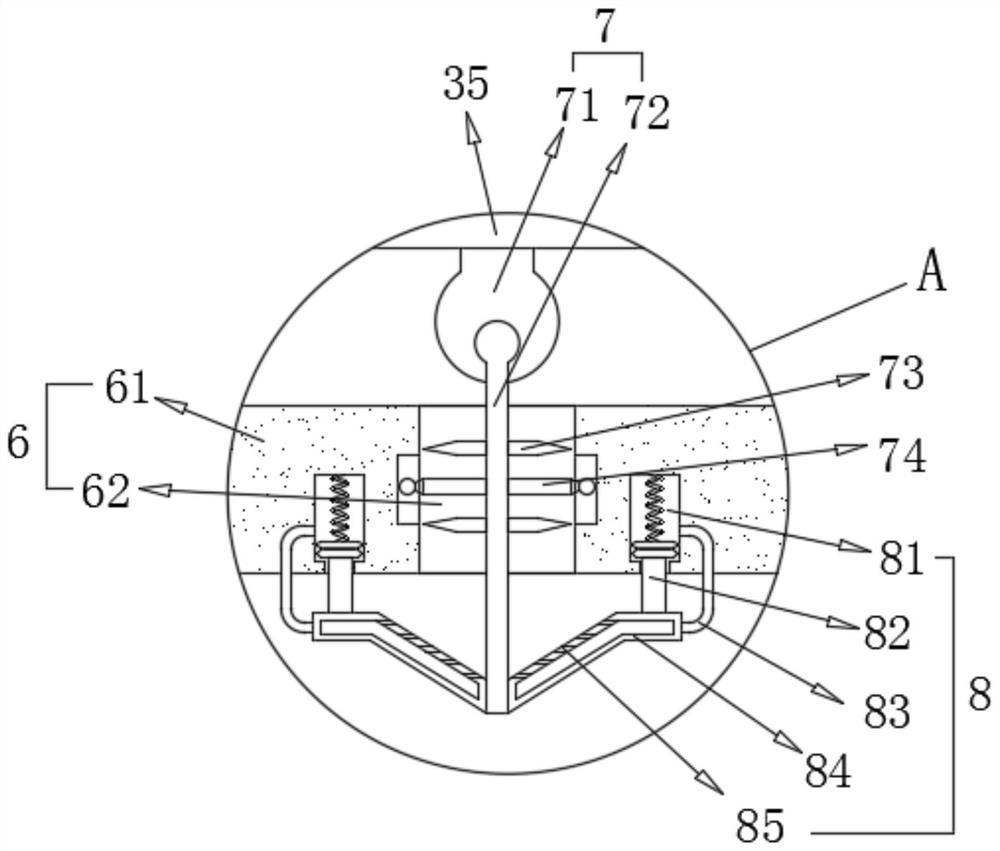

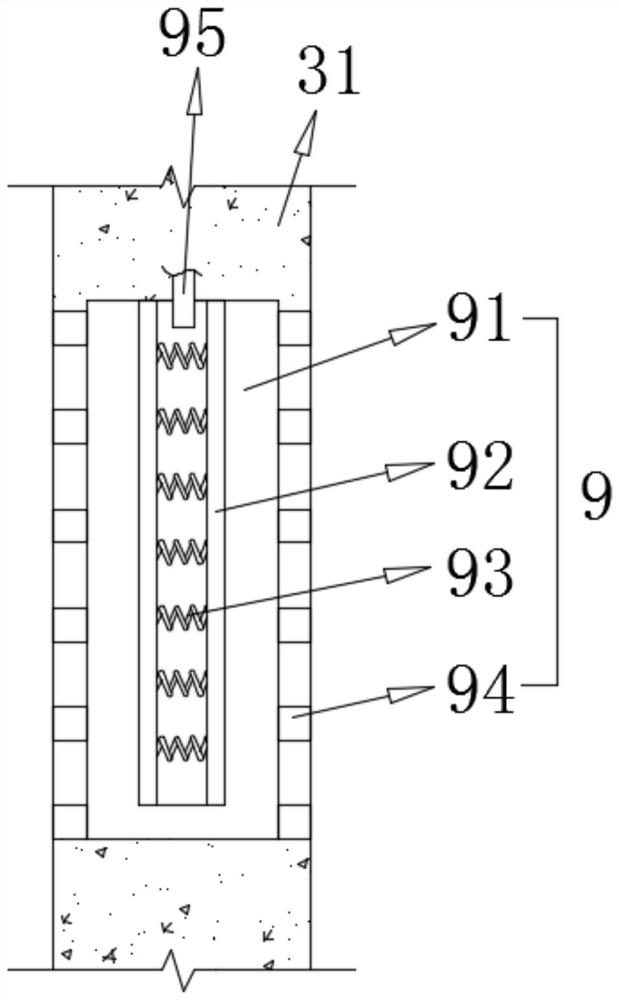

[0033] Refer Figure 1 to 3 , A mixed ratio device for producing a polyurea waterproof coating, including a housing 1, and a stirring mechanism 3 is provided inside the housing 1 for mixing the ratio material, and the mixing mechanism 3 includes a activity setting. The rotating member 31, the side surface of the rotating member 31 is provided with a second agitating member 34, further comprising a drive member 32 for driving the rotating member 31, further comprising an upper mechanism 2 for adding a material to the housing 1, As well as the lower material 10, a baffle mechanism 6 is provided in the inside of the housing 1 for a limiting block for the internal material of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com