Anchor tension plate type anchoring structure cable and tensioning construction method thereof

A technology of anchoring structure and anchoring plate, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems such as the inability to adjust the tension of the pinned cable structure, the inconvenient tension operation, and the weakening of the box girder structure. , to achieve the effect of compact structure, not easy to accumulate water and rust, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

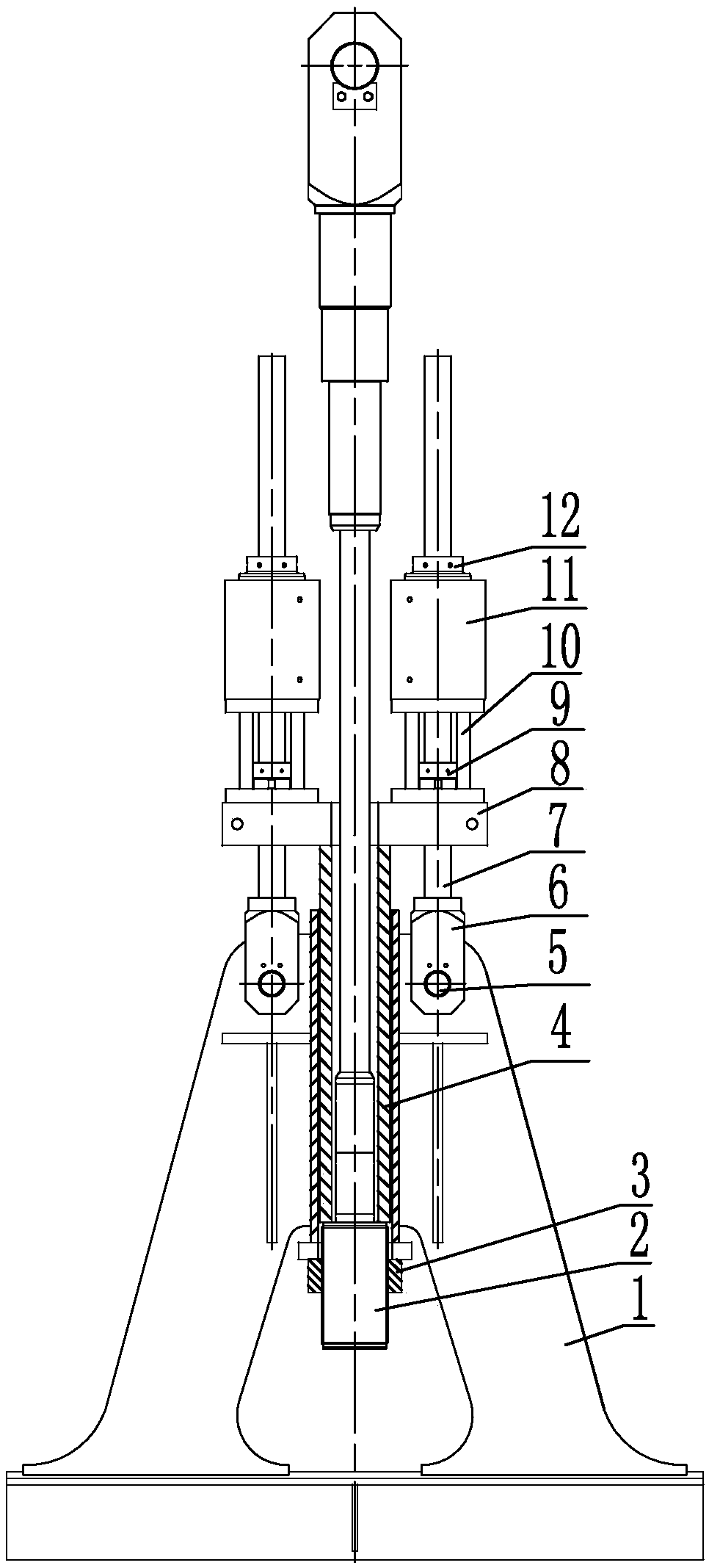

[0107] A kind of anchor pull plate type anchoring structure cable and its tension construction method with reaction force structure ear plate I of reaction force structure:

[0108] Such as Figure 1-1~Figure 1-2 As shown, the anchor plate type anchor structure cable with the anti-force structure ear plate I includes the anchor plate I1a with the anti-force structure, the cable anchor 2, the anchor nut 3 and the tension mechanism;

[0109] The anchor plate I1a with reaction force structure includes a bridge deck 101, two anchor plate main plates I 102a, an anchor backing plate 103, a steel pipe I 104a, an anchor plate sealing plate 105, a reinforcing rib plate 106, and a steel pipe I 104a Located in the middle of the two anchor plate main plates I 102a, the two anchor plate main plates I are fixedly connected into a whole, the anchor pad 103 with an anchor hole in the middle is fixed at the bottom of the steel pipe I 104a, and the anchor hole axis of the anchor pad 103 is connected ...

Embodiment 2

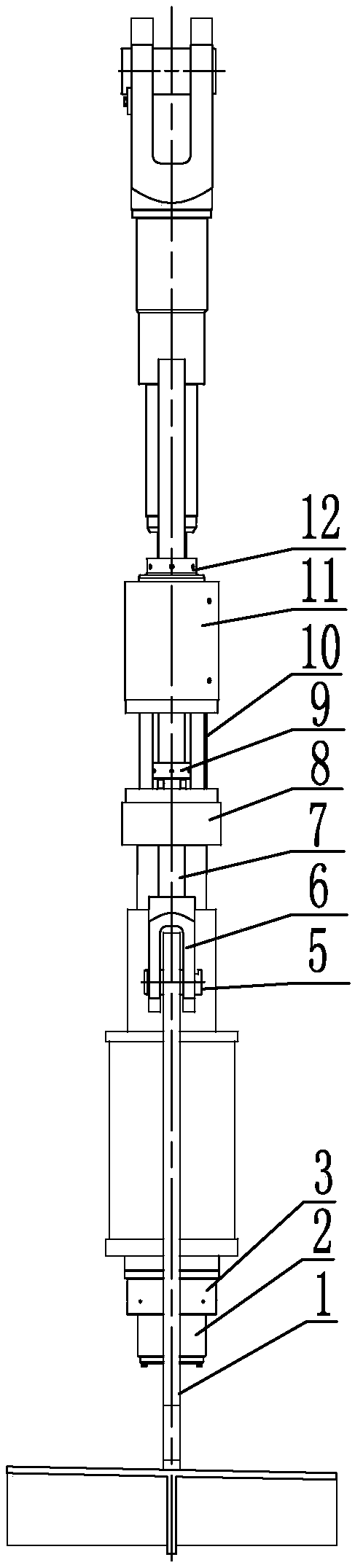

[0127] One kind of reaction force structure is a steel pipe reaction force integrated step or a threaded steel pipe and nut combined step anchor pull plate type anchor structure cable:

[0128] Such as Figure 2-1~Figure 2-2 As shown, the reaction force structure is a steel pipe reaction force integrated step or a threaded steel pipe and nut combined step anchor pull plate type anchor structure. The pull cable anchor pull plate type anchor structure. The pull cable includes an anchor pull with a reaction force structure. Plate II1b, cable anchor 2, anchor nut 3 and tension mechanism;

[0129] The anchor plate II 1b with reaction force structure includes bridge deck 101, two anchor plate main boards II 102b, anchor pad 103, steel pipe II 104b, anchor plate sealing plate 105 and stiffener plate 106, steel pipe Ⅱ104b is located in the middle of the two anchor plate main plates Ⅱ102b. The two anchor plate main plates Ⅱ are fixedly connected into a whole. The anchor pad 103 with an anch...

Embodiment 3

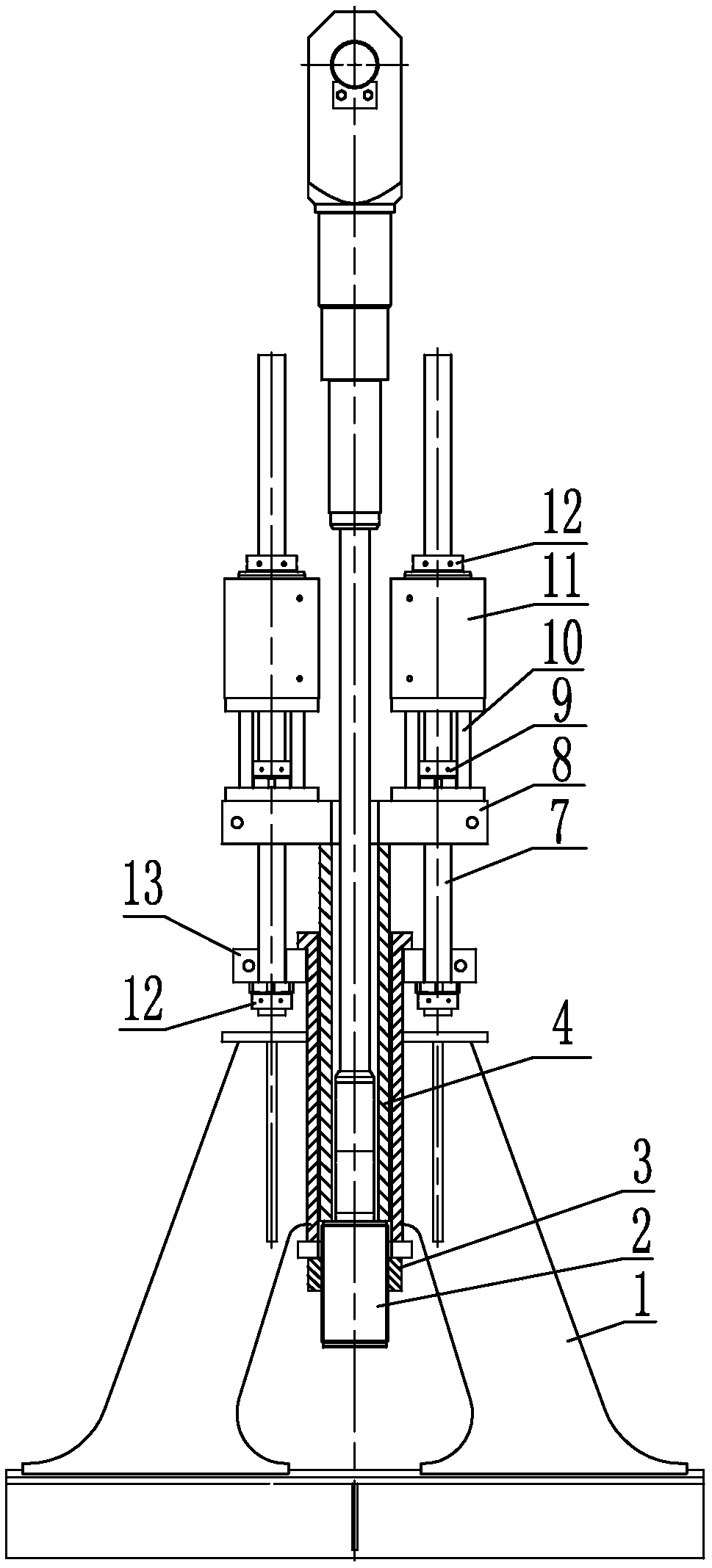

[0150] A kind of anchor pull plate type anchoring structure cable with anti-force structure ear plate II and its tension construction method:

[0151] Such as Figure 10-1~Figure 10-2 As shown, the basic structure of the anchor plate type anchoring structure cable whose reaction force structure is a reaction force structure lug plate is the same as the first embodiment, and the difference from the first embodiment is:

[0152] The anchor plate 1 of the anchor plate type anchor structure cable is an anchor plate III 1c with a reaction force structure. The anchor plate III 1c with a reaction force structure includes a bridge deck 101, two anchor plate main plates II 102b, The anchor pad 103, the steel pipe I 104a, the anchor plate sealing plate 105 and the reinforcing rib plate 106, the steel pipe I 104a is located in the middle of the two anchor plate main plates II 102b, and the two anchor plate main plates II are fixedly connected into a whole. The anchor plate 103 of the anchor h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com