AC high voltage vacuum breaker

A vacuum circuit breaker, high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve complex manufacturing process, closing time, opening time position return response time, low flexibility, etc. problems, to achieve rapid communication, fast action, and ensure timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

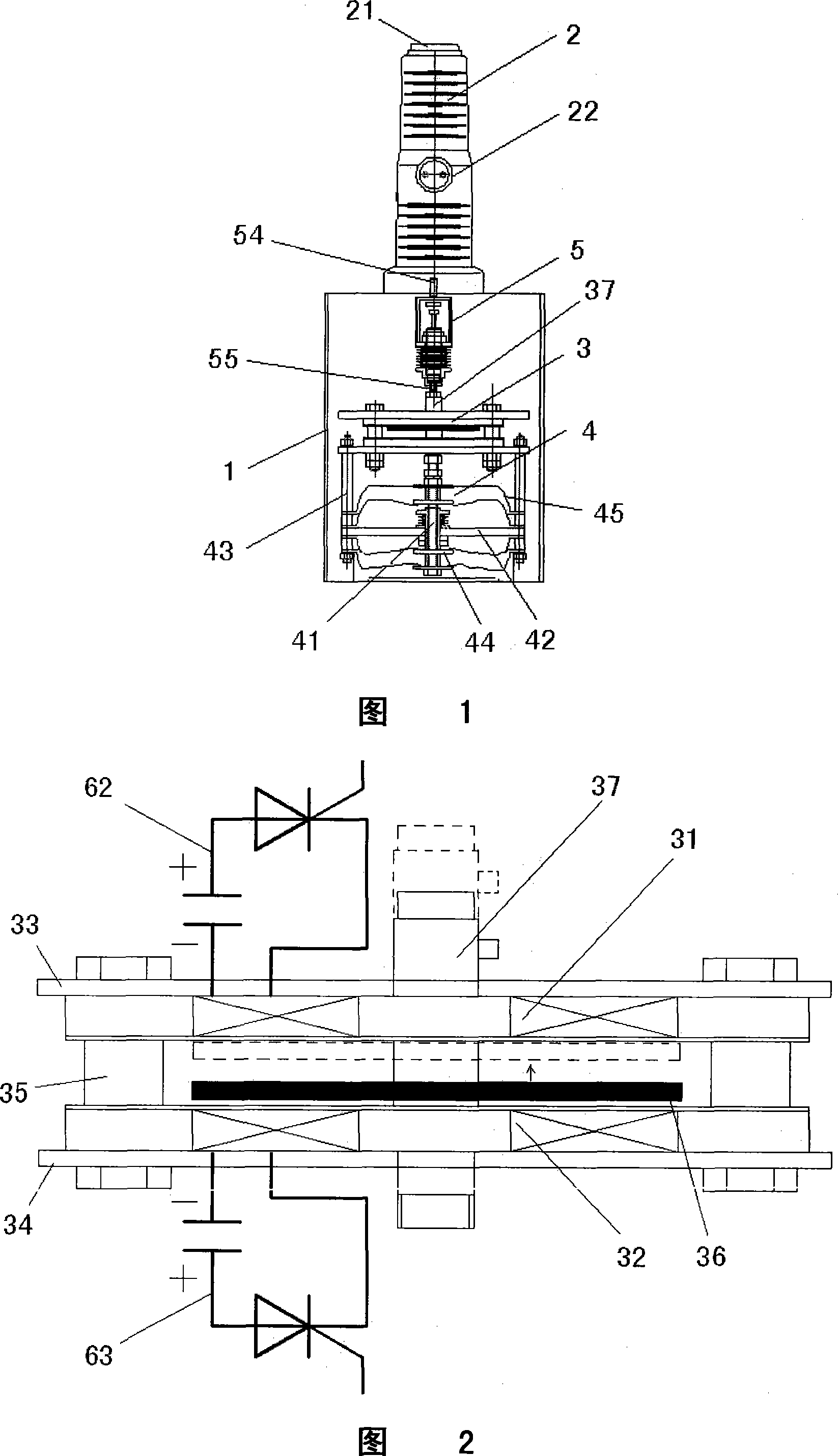

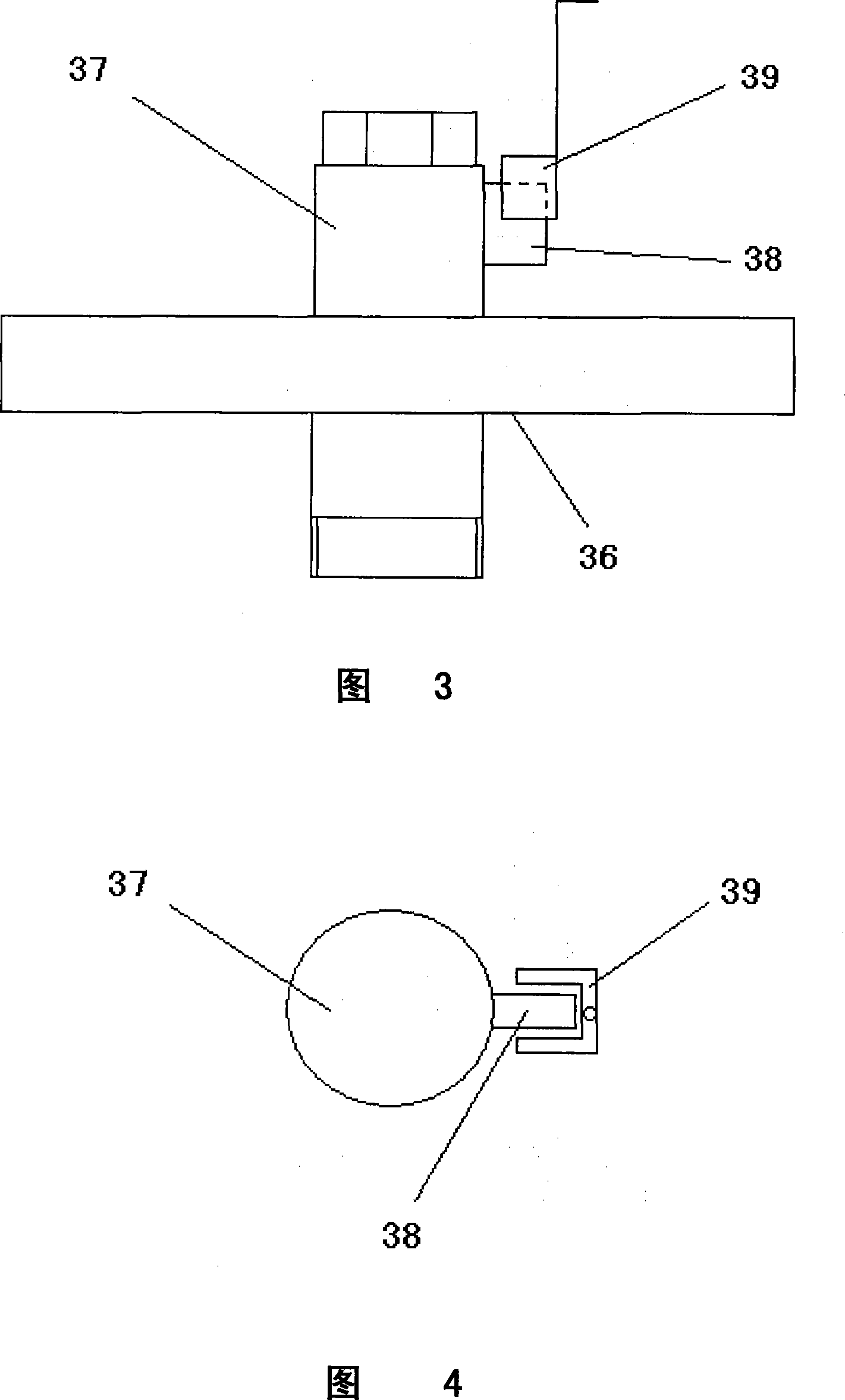

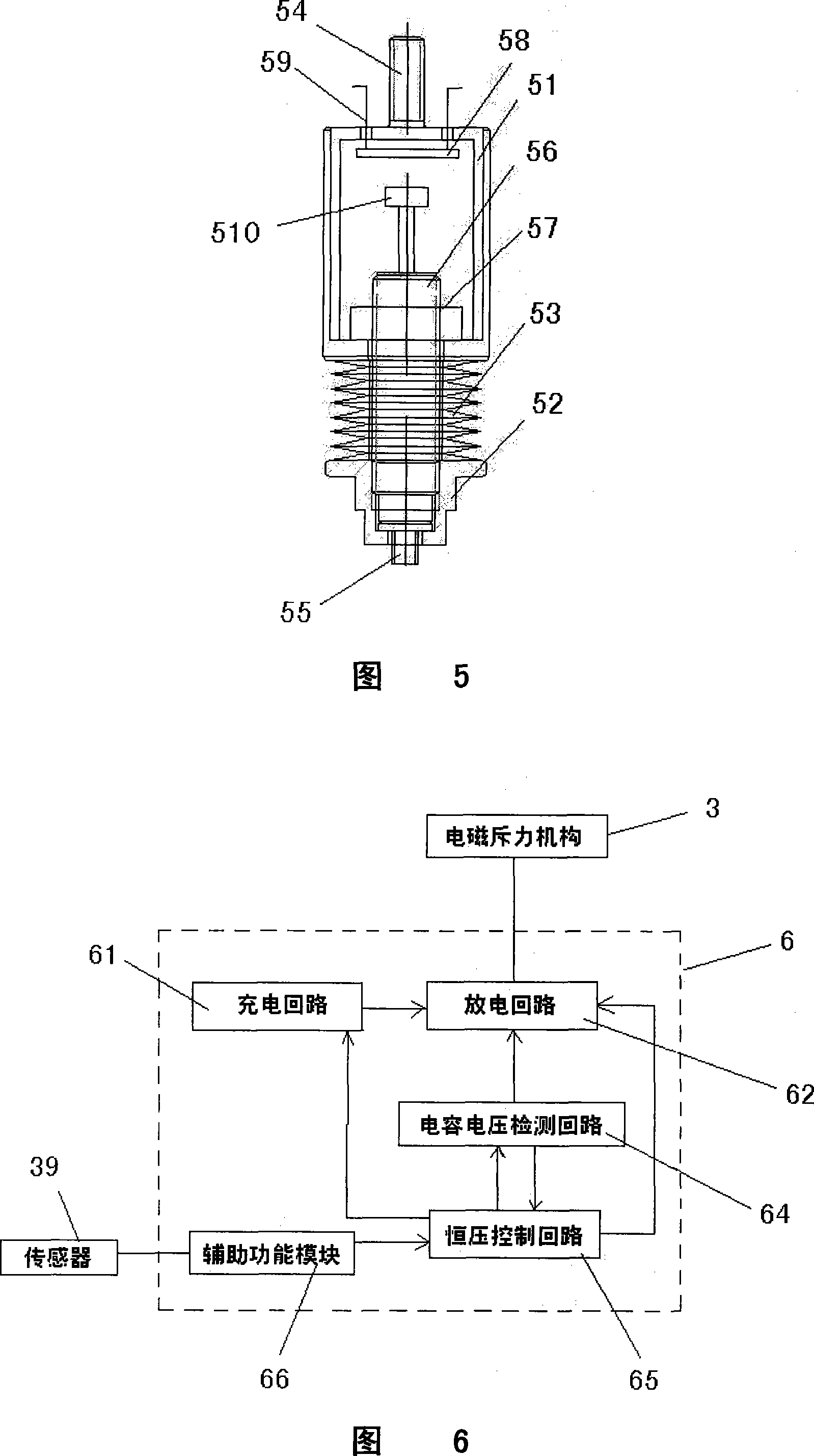

[0028] As shown in Figure 1, the structural part of the AC high voltage vacuum circuit breaker of the present invention mainly includes a circuit breaker box 1, a solid-sealed pole vacuum interrupter 2 is seated on the box 1, and an electromagnetic circuit breaker is arranged in the middle of the box 1. The repulsion mechanism 3, the lower end of the electromagnetic repulsion mechanism 3 is connected to a combined disc spring retention mechanism 4, the upper end of the electromagnetic repulsion mechanism 3 is connected to a closing buffer mechanism 5, and the top of the closing buffer mechanism 5 passes through the box body 1 and vacuum arc extinguishing Room 2 is connected.

[0029] The vacuum interrupter 2 adopts the existing technology, and the main circuit electrical components are insulated and sealed with epoxy glue mixed with a curing agent. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com