Passive highly-sensitive impact sensor based on piezoelectrets and testing method thereof

An impact force sensor, piezoelectric electret technology, applied in the direction of force/torque/work measurement instrument calibration/test, force/torque/work measurement instrument, instrument, etc., can solve the structural damage of piezoelectric ceramics, difficult to accurately Measure weak impact force, low piezoelectric sensitivity, etc., to achieve excellent mechanical properties, low consumption, high efficiency sensitivity, and ultra-high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

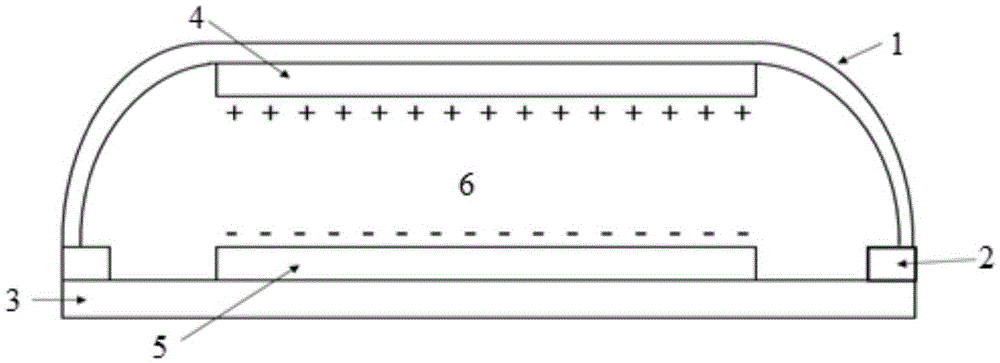

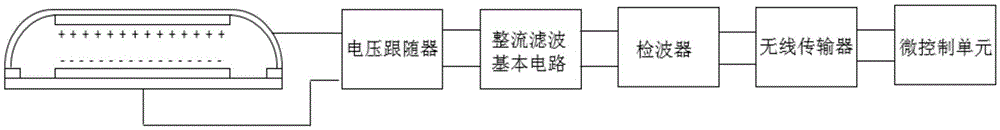

[0024] Such as figure 1 As shown, the passive high-sensitivity impact sensor based on piezoelectric electret in this embodiment includes: shrapnel electrode 1, insulating gasket 2, back electrode 3, shrapnel electrode electret layer 4, back electrode electret layer 5. Cavity 6, wires and test circuit; wherein, the back electrode 3 is flat and adopts a conductive metal material; on the upper surface of the back electrode 3 and around the electret, an insulating gasket 2 is provided; the shrapnel electrode 1 The insulating gasket 2 is arranged on the back electrode 3, and the insulating gasket 2 electrically insulates between the shrapnel electrode 1 and the back electrode 3; the back electrode electret layer 5 is closely attached to the upper surface of the back electrode 3, and the shrapnel electrode The electret layer 4 is closely attach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com