Axial force pre-loading structure of deep groove ball bearing in engine rotor fulcrum

A deep groove ball bearing and axial force technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low-pressure shaft flying, blade breakage, etc., and achieve the effect of huge application potential and large technology expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

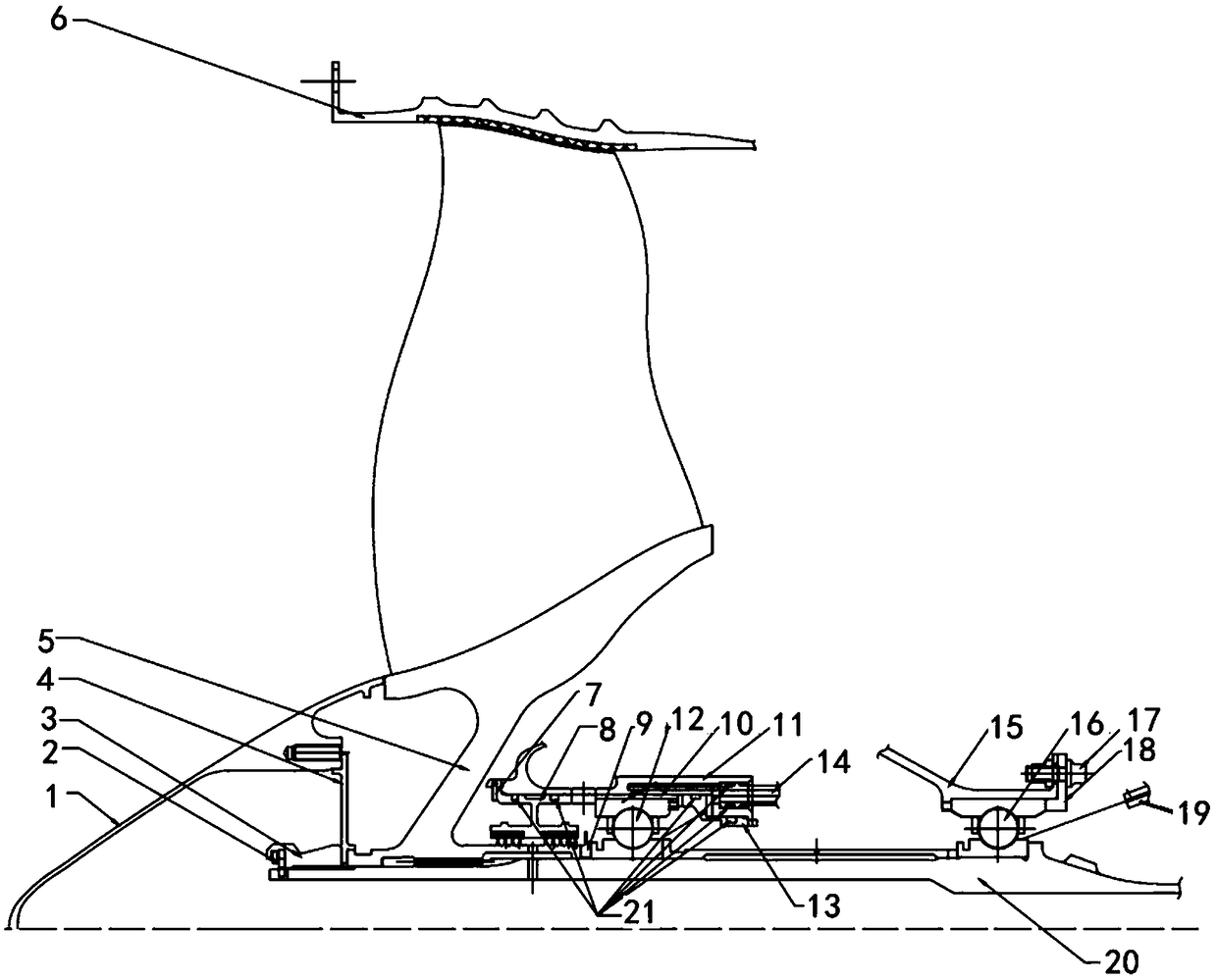

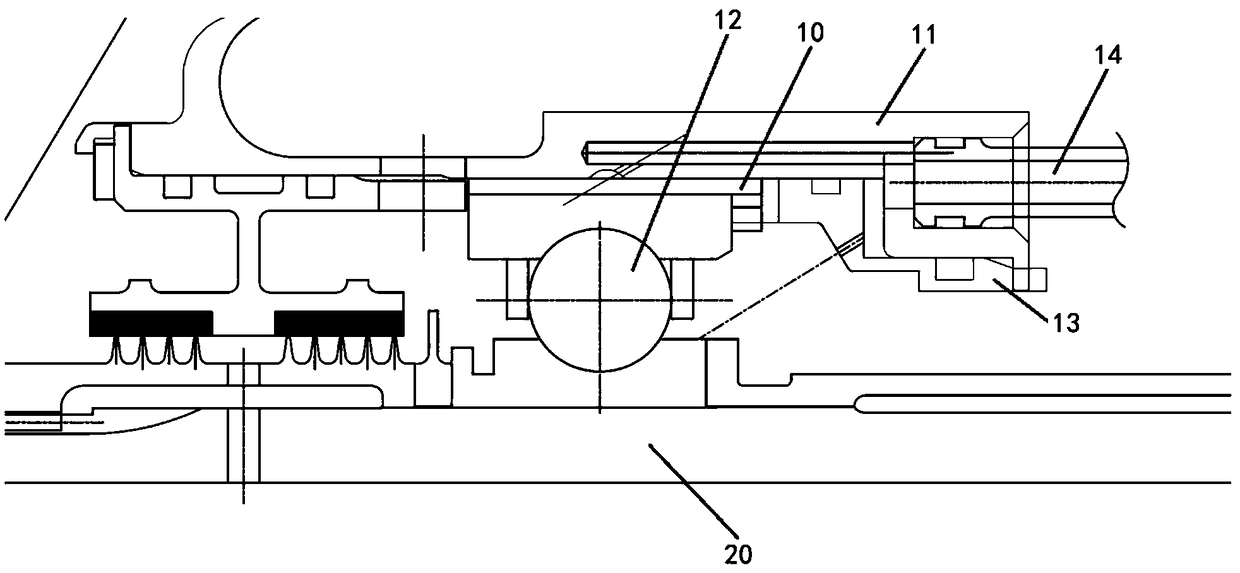

[0018] Such as figure 1 , 2 As shown, this embodiment is a design scheme of an axial preloading structure for a deep groove ball bearing at the fan end fulcrum of a certain twin-shaft aviation turbofan engine. In the figure, 1: intake cone; 2: screw retaining ring for nut; 3: tighten nut; 4: intake cone rotating ring; 5: fan rotor; 6: fan casing; 7: spiral retaining ring; 8: grating gear ring; 9: oil retaining ring; 10: elastic ring; 11: bearing seat; 12: deep groove ball bearing; 13: oil collecting ring; 14: oil supply pipe; 15: bearing seat; 16: thrust deep groove ball Bearing; 17: flared self-locking nut assembly; 18: bearing stop ring; 19: oil supply nozzle; 20: low pressure shaft; 21: O-shaped rubber ring. In this embodiment, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com