Large-tonnage static-load test counter-force structure and static-load test device

A static load test, large tonnage technology, applied in the direction of infrastructure engineering, foundation structure test, construction, etc., can solve the problem of large deviation of measurement results and achieve high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

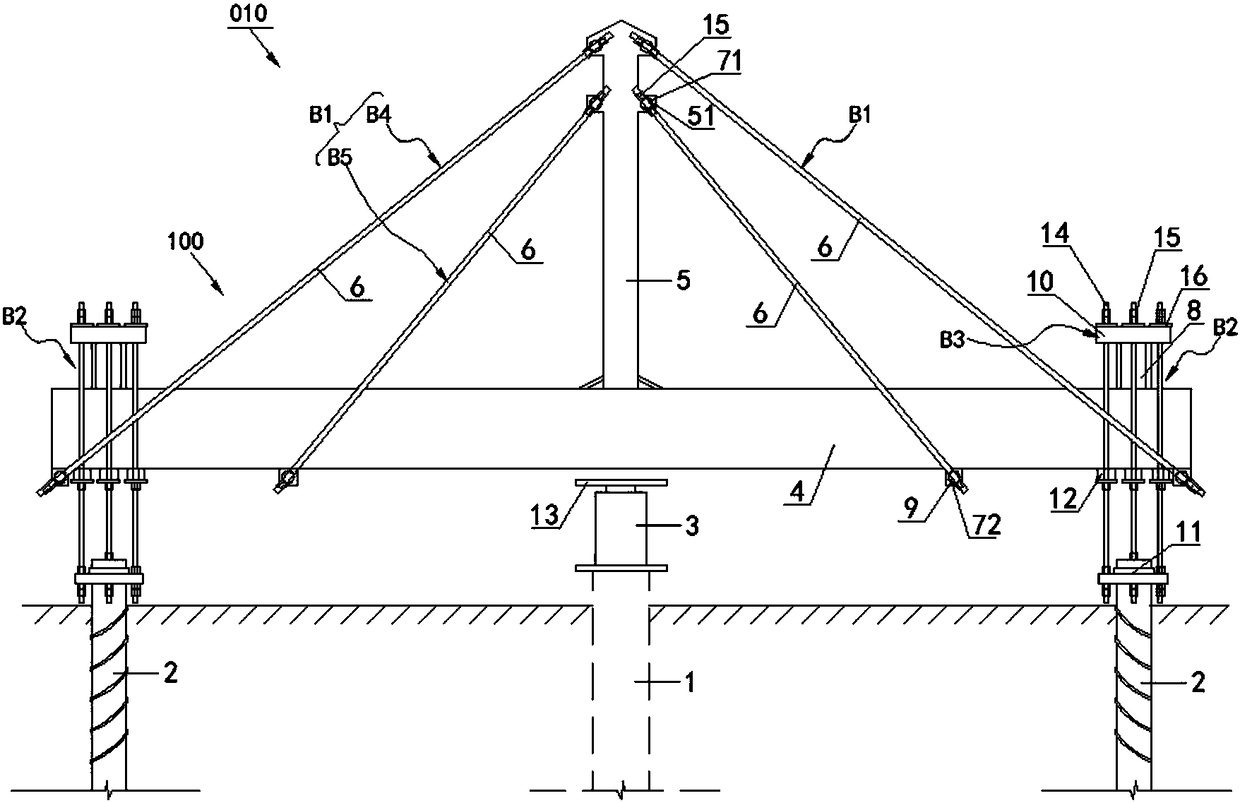

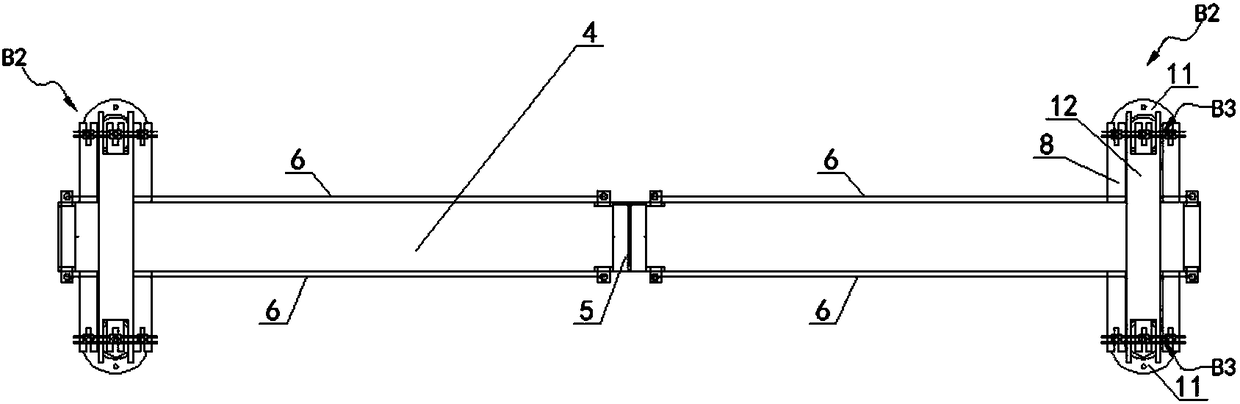

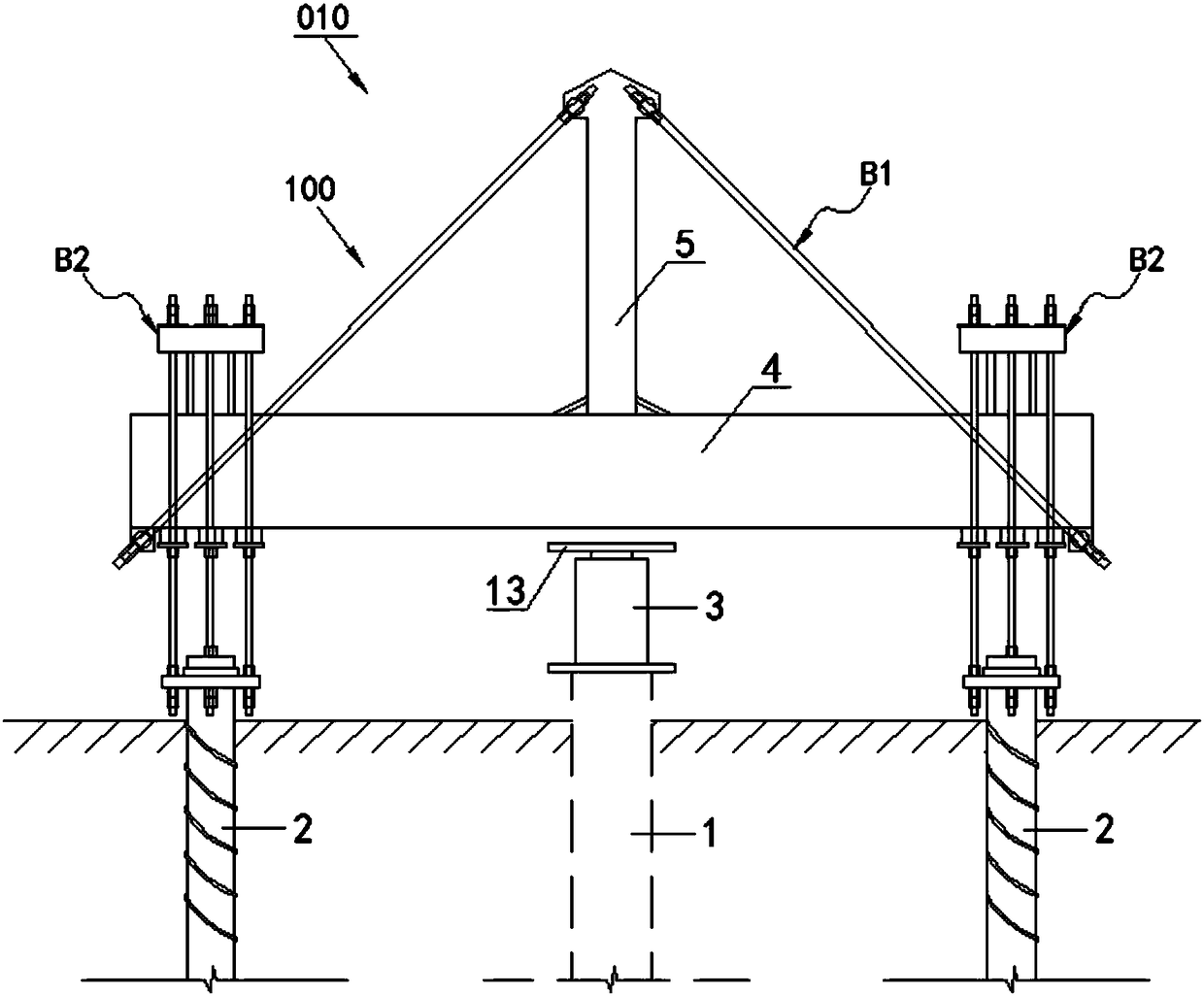

[0048] figure 1 shows a structural view of an implementation of the static load test device 010 in the embodiment of the present invention (additionally shows the foundation pile 1 to be tested with a dotted line in the figure); figure 2 for figure 1 top view.

[0049] see figure 1 , figure 2 , the embodiment of the present invention also provides a static load test device 010, which includes a jack 3 and a large tonnage static load test reaction force structure 100. The force jack 3 is configured to be vertically supported on the upper surface of the foundation pile 1 to be tested, and the large-tonnage static load test reaction force structure 100 is supported on the force jack 3 for providing reaction force. Its use method is that the large-tonnage static load test reaction force structure 100 is fixedly connected to the foundation, and the jacking force 3 applies jacking force to the large-tonnage static load test reaction force structure 100, and the counterforce of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com