Novel foam fire truck and foam supplying and conveying device

A foam fire truck and conveying device technology, which is applied in fire rescue and other directions, can solve the problems of affecting fire fighting, limited site, and small foam liquid flow, so as to improve the foam liquid supply capacity, improve fire extinguishing capacity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

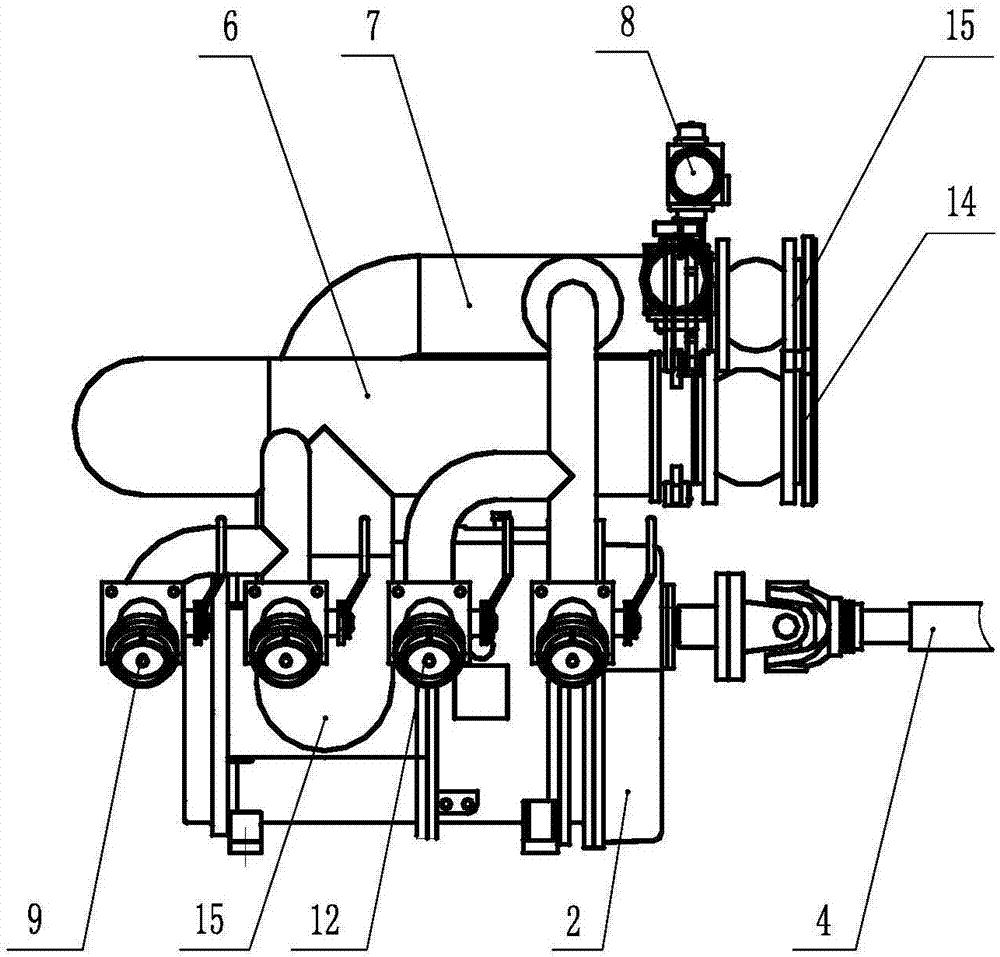

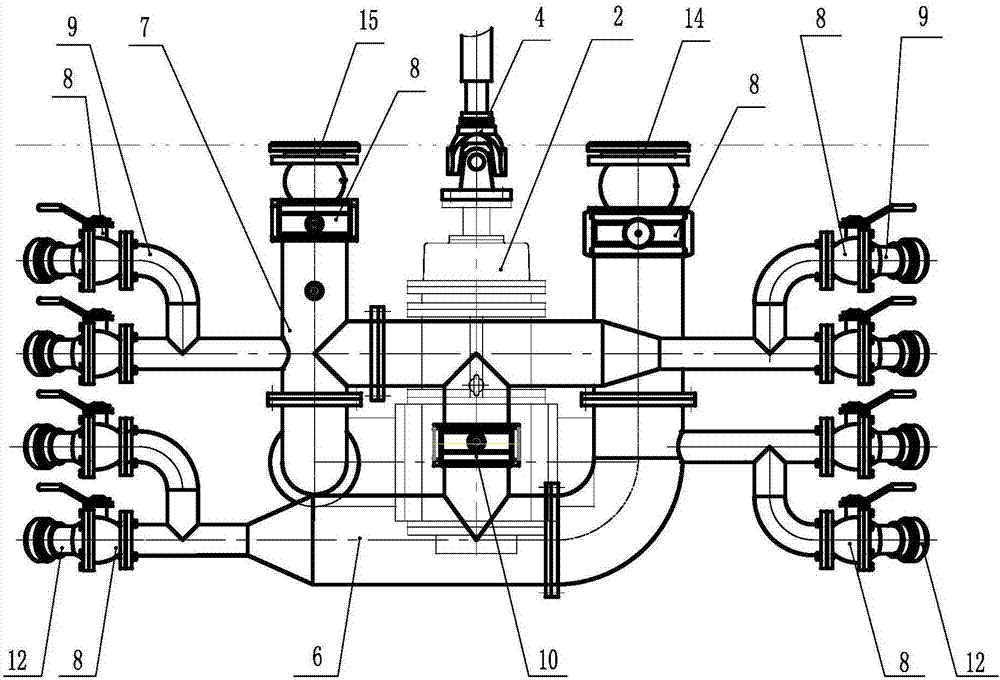

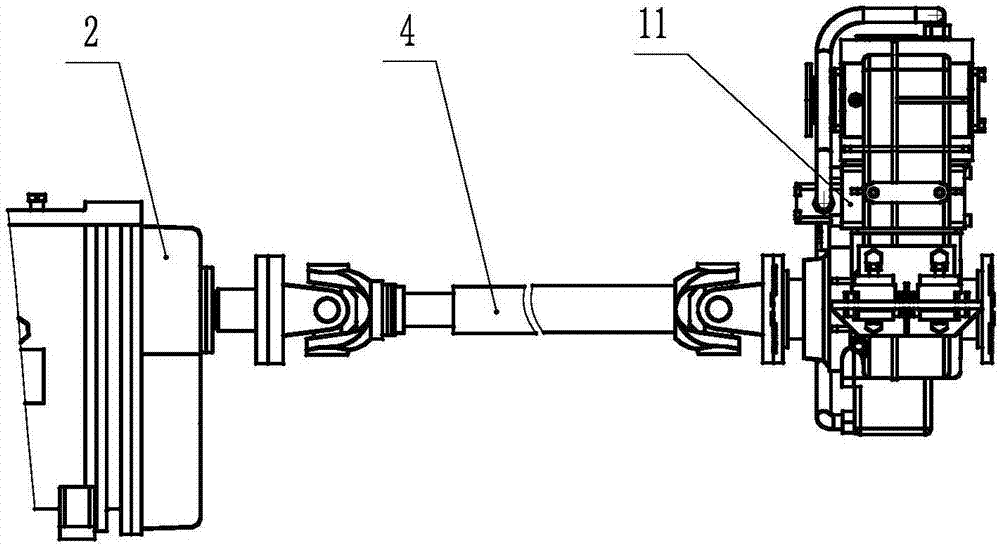

[0038] Figure 1 to Figure 5 Some embodiments according to the invention are shown.

[0039] combined reference figure 1 , the foam supply and delivery device of the present invention is used on a foam fire truck, comprising a foam pump 2, a foam liquid inlet pipeline 6 and a foam liquid outlet pipeline 7, wherein the foam liquid inlet pipeline 6 and the foam liquid The liquid suction port of the pump 2 is communicated, the foam liquid outlet pipeline 7 is communicated with the liquid outlet of the foam pump 2, and the foam liquid inlet pipeline 6 includes a first foam tank communication port 14 and a plurality of foam liquid inlets Interface 12, the foam outlet pipeline includes a second fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com