Thin capillary structure supporting uniform temperature plate

A capillary structure and temperature chamber technology, which is used in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of high rejection rate, complex sealing operation, and increased processing flow and difficulty of temperature chamber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

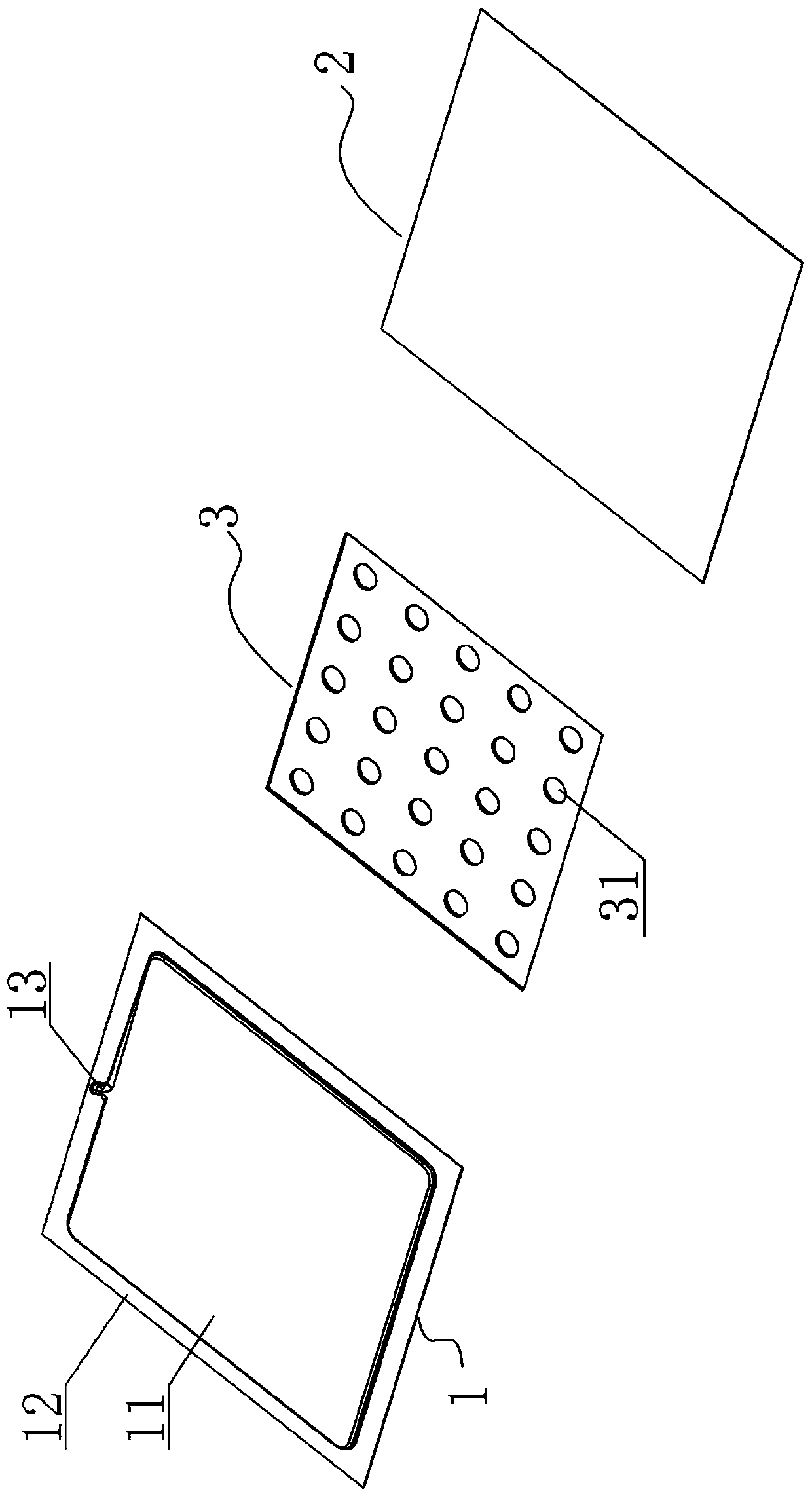

[0028] Specific embodiment one, see figure 1 : The support member 31 is specifically cylindrical.

specific Embodiment 2

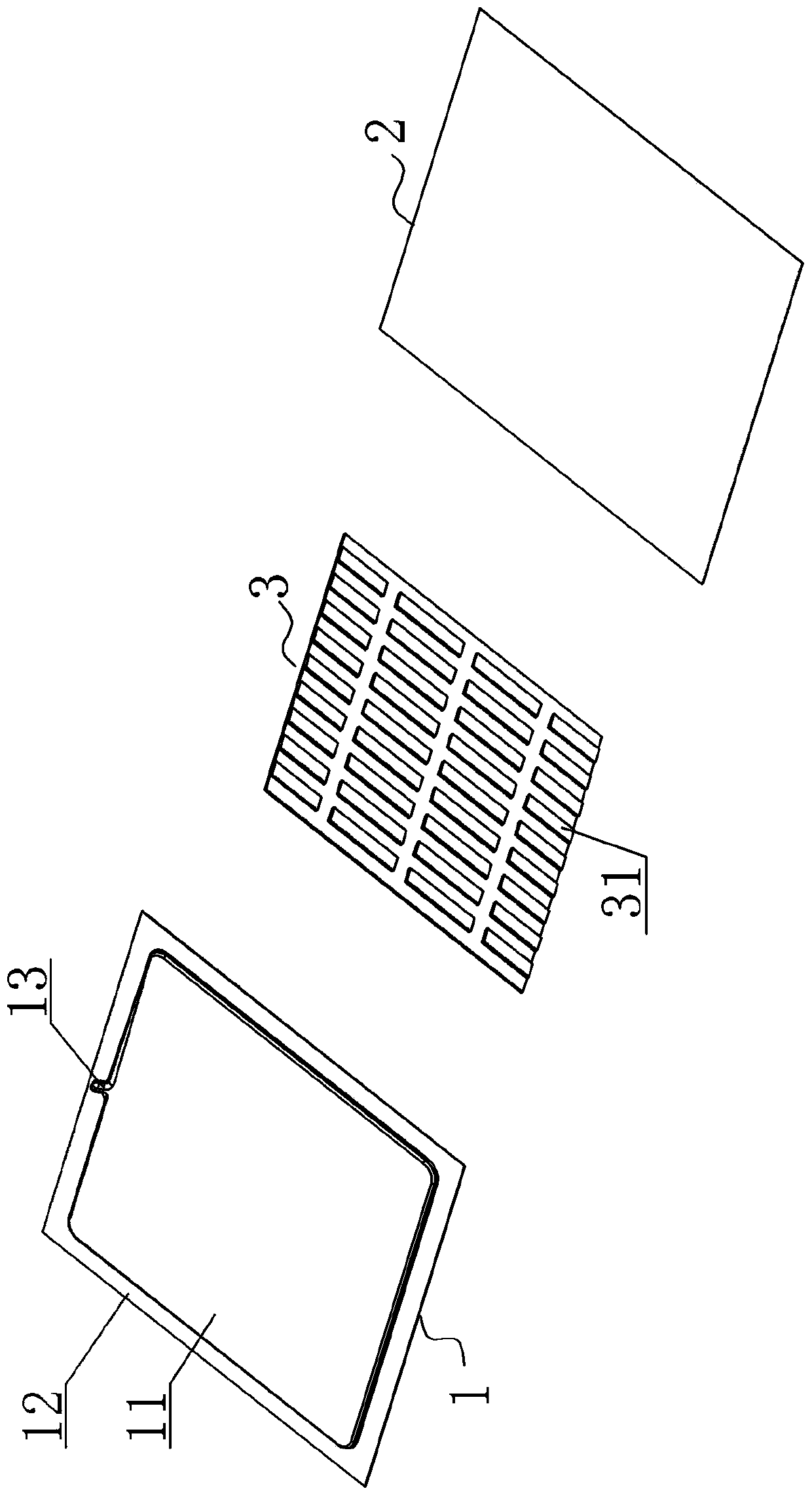

[0029] Specific embodiment two, see figure 2 : The support member 31 is specifically in the shape of a cube.

specific Embodiment 3

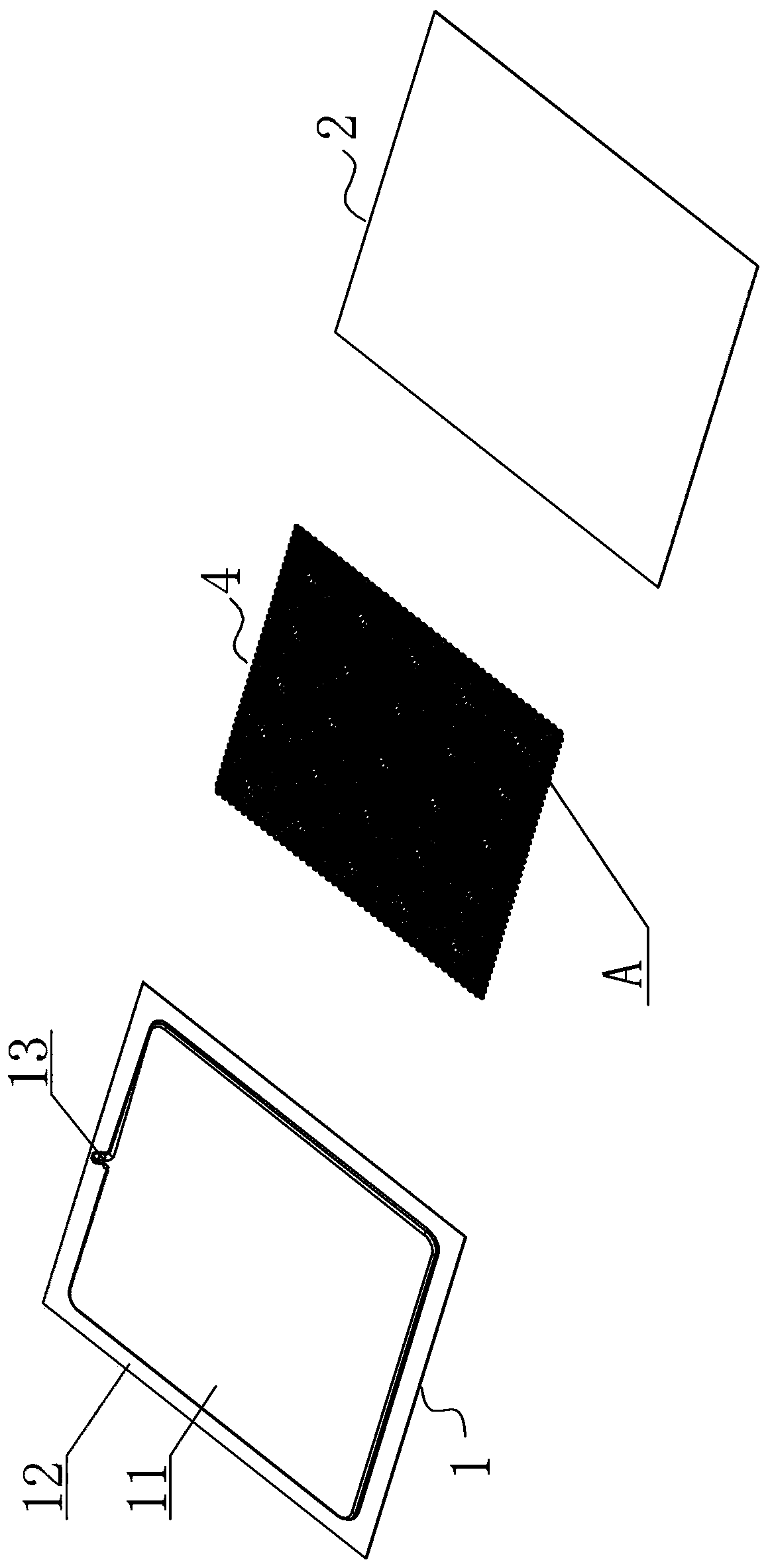

[0030] Specific embodiment three, see image 3 and Figure 4 : The capillary support structure is specifically a mesh support structure 4 formed by assembling capillary metal tubes, the capillary metal tubes of the mesh support structure 4 are filled with working fluid, and the mesh support structure 4 is arranged corresponding to the inner surface of the second cover plate 2 There are several convex three-dimensional braided protrusions 41, and the outer convex points of the three-dimensional braided protrusions 41 arranged in an array form an equivalent plane, and the outer convex points of all the three-dimensional braided protrusions 41 fit the second cover plate The inner surface of the corresponding position arrangement.

[0031] Its beneficial effects are as follows:

[0032] The capillary structure functions as the capillary force structure of the vapor chamber phase change medium while forming a supporting structure. The two cover plates of the vapor chamber no long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com