Large-section U-shaped earth pressure balance shield tunnel construction method based on U-shaped shield tunneling machine

A technology for earth pressure balance shield tunneling and tunnel construction, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as uneven mixing effects, increased resistance between cutterhead and incision, and cumbersome procedures, so as to improve transportation efficiency. , saving construction costs, and improving the effect of the environment in the cave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

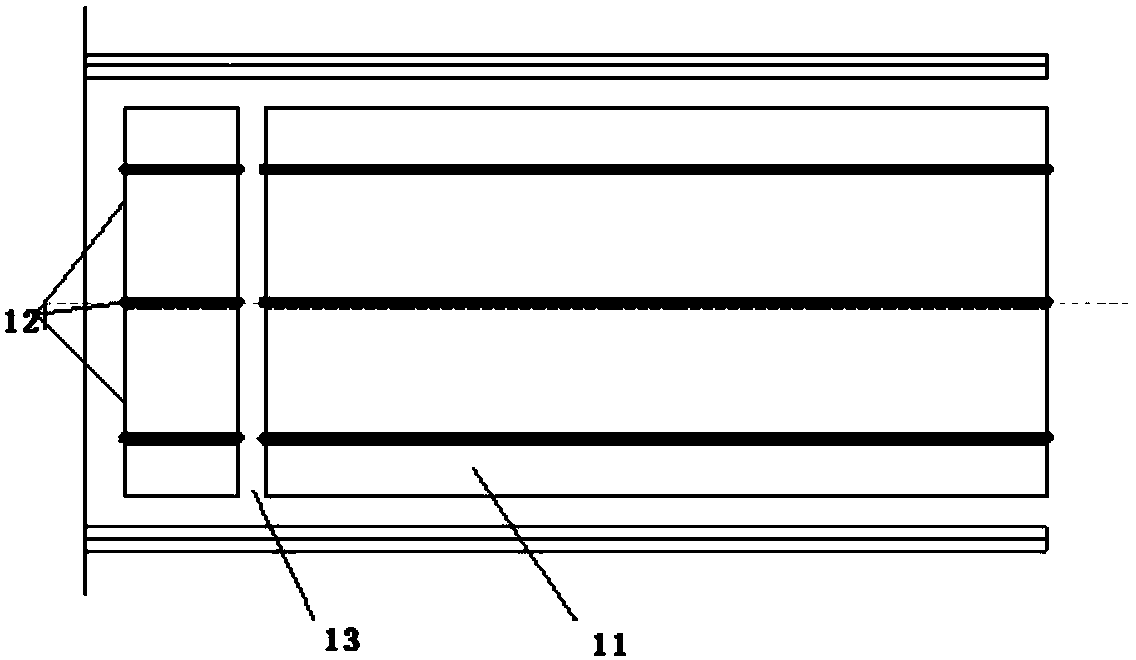

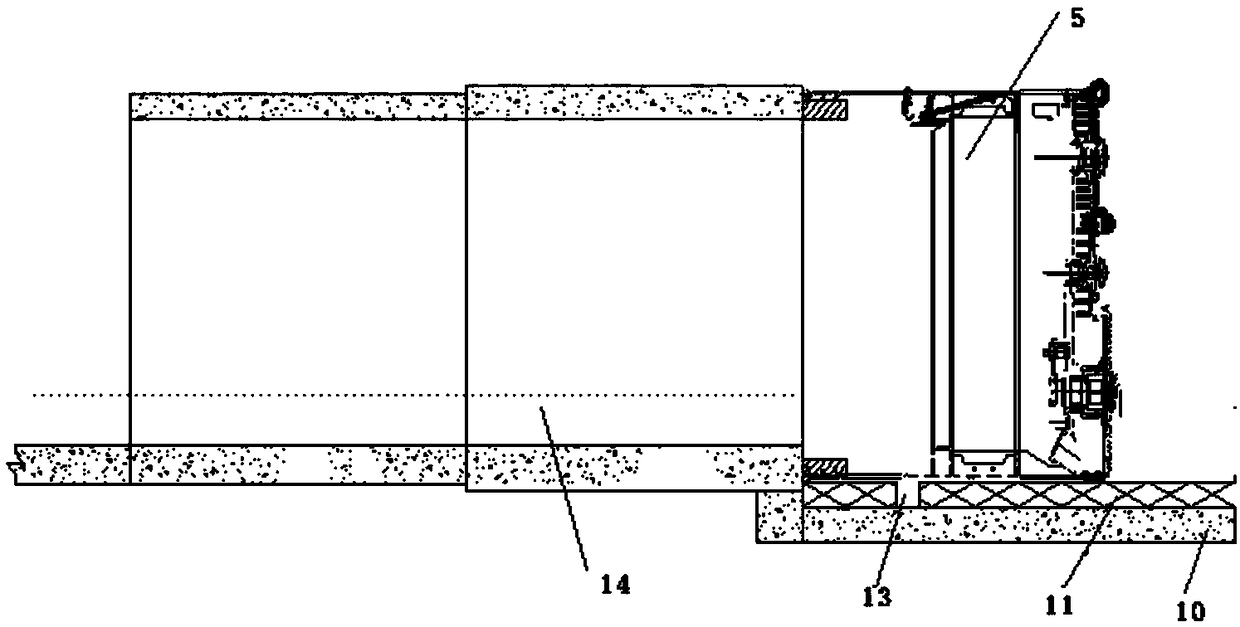

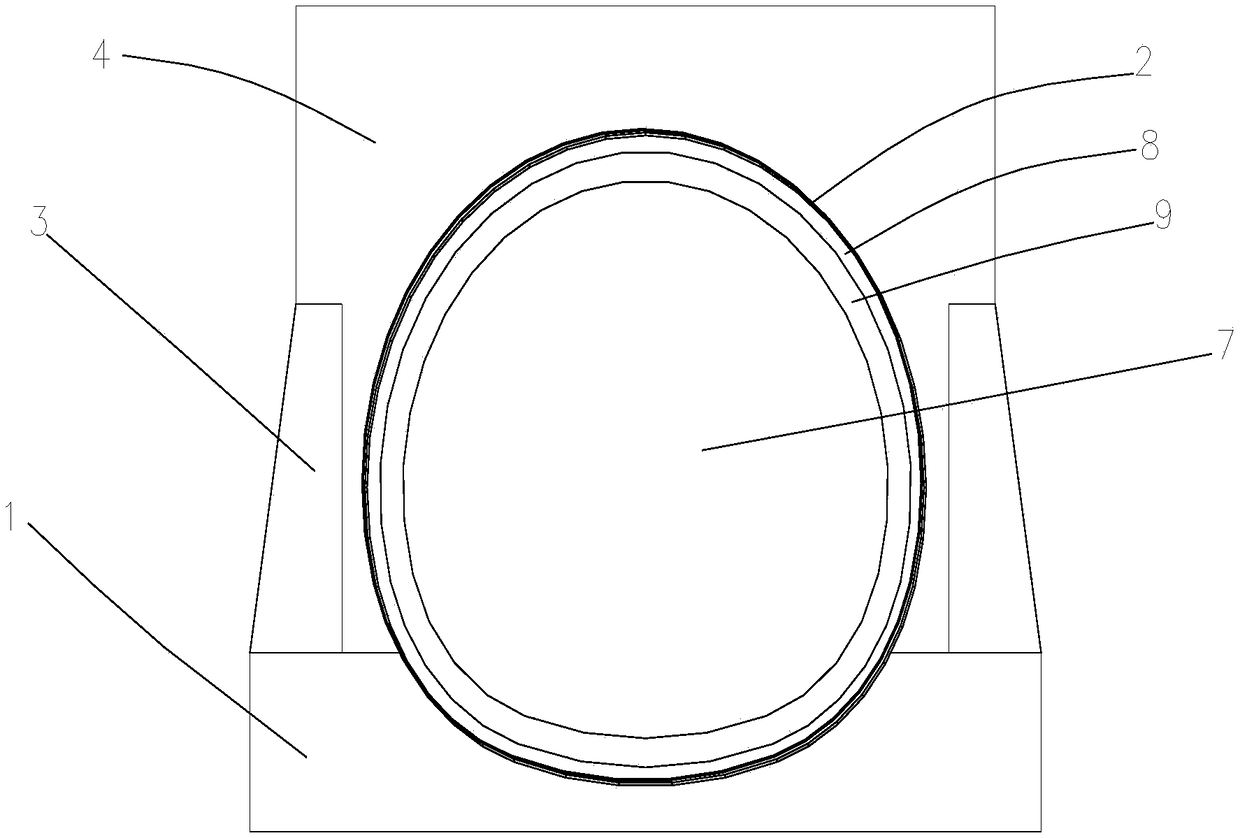

[0067] A large-section horseshoe-shaped earth pressure balance shield tunnel construction method based on a horseshoe-shaped shield machine mainly includes the following steps:

[0068] Step 1: Set up the starting device of the open hole reaction force structure shield, the end is reinforced, and the end is reinforced with a large pipe shed in the direction of the long distance, with a length of 40m. At the beginning of excavation, through the sealing device of the cave door and the pressure keeping measures during the excavation process, the stability of the cave top strata can be ensured, and no other end reinforcement measures are required. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com