License plate thermoprinting machine with rapid heating and stable temperature control functions

A rapid heating and hot stamping machine technology, which is applied to printing machines, rotary printing machines, printing, etc., can solve the problems of a large number of manual operations, low control precision, and bearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

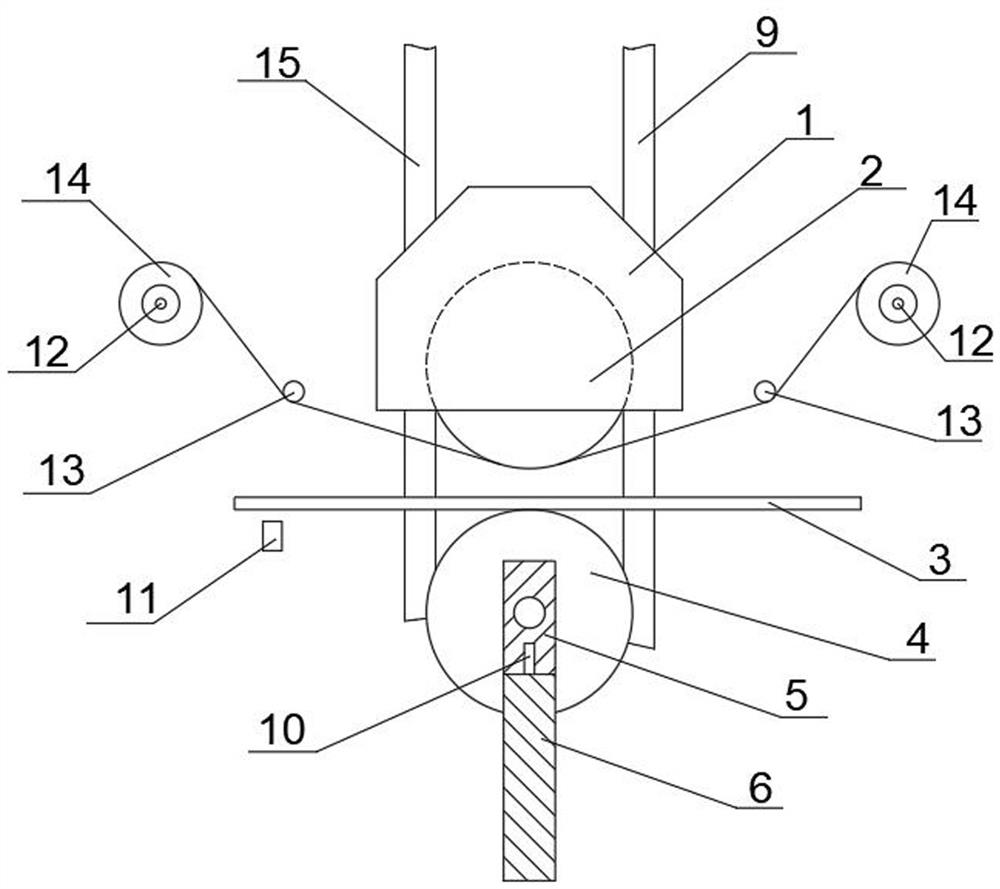

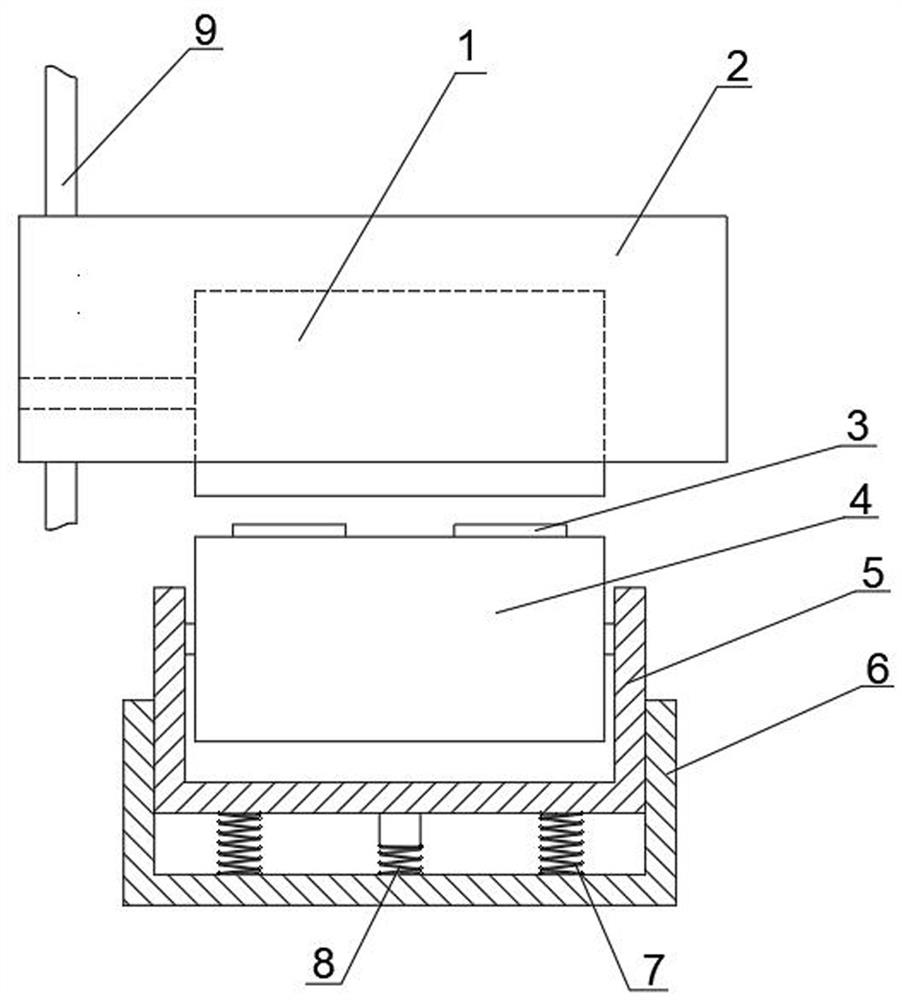

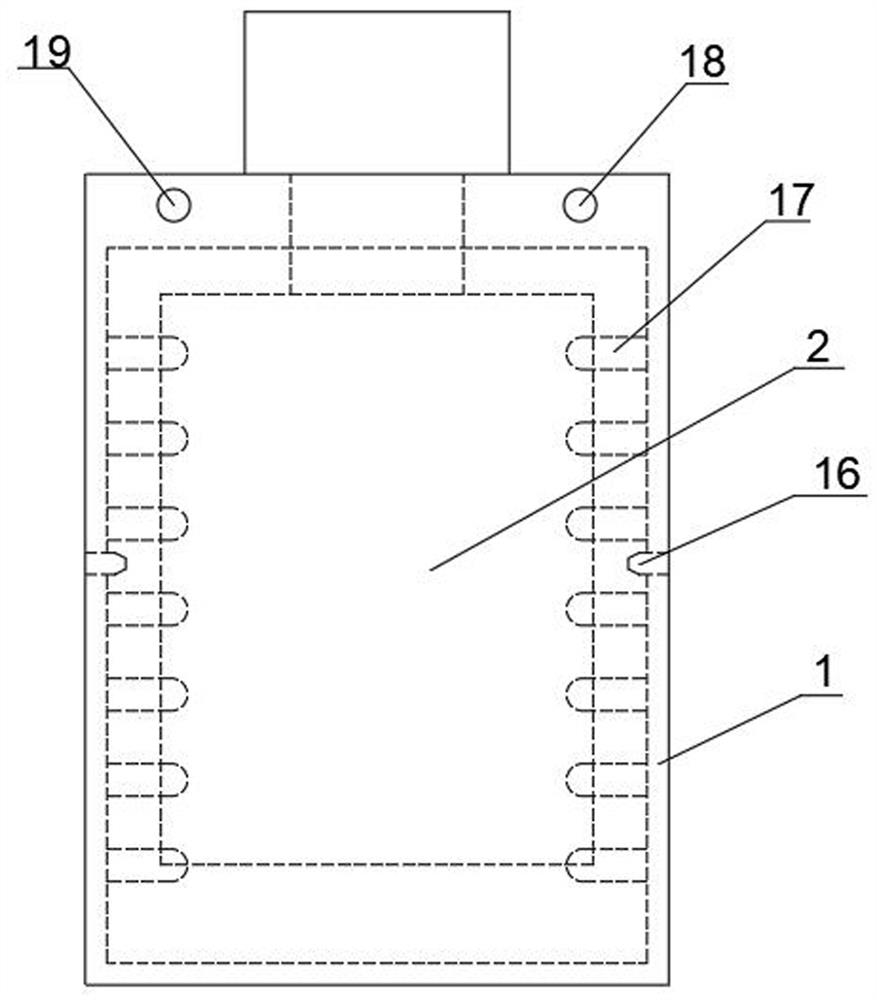

[0036] Such as Figure 1-7 As shown, a license plate hot stamping machine with rapid heating and stable temperature control includes a heating cover 1, an upper pressure roller 2, a lower pressure roller 4, a conveyor belt 3, a carbon ribbon shaft 12 and a control system, and the upper pressure roller 2 is rotatable is arranged in the heating mantle 1, the bottom of the upper pressure roller 2 protrudes from the bottom of the heating mantle 1, the conveyor belt 3 is located between the upper pressure roller 2 and the lower pressure roller 4, the rolling direction of the upper pressure roller 2 is A carbon belt shaft 12 is respectively arranged in the front and rear directions, a heating cylinder 21 is arranged in the upper pressure roller 2, the heating cover 1 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com