A vpce system capable of automatic monitoring sampling analysis and its technology

A sampling analysis and automatic monitoring technology, applied in the analysis of materials, nuclear engineering, instruments, etc., can solve the problems of inability to adjust the height of the water vapor inlet and hydrogen inlet, low degree of automation, waste of energy, etc., to achieve catalytic exchange Reaction effect Energy saving, high degree of automation, scientific and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

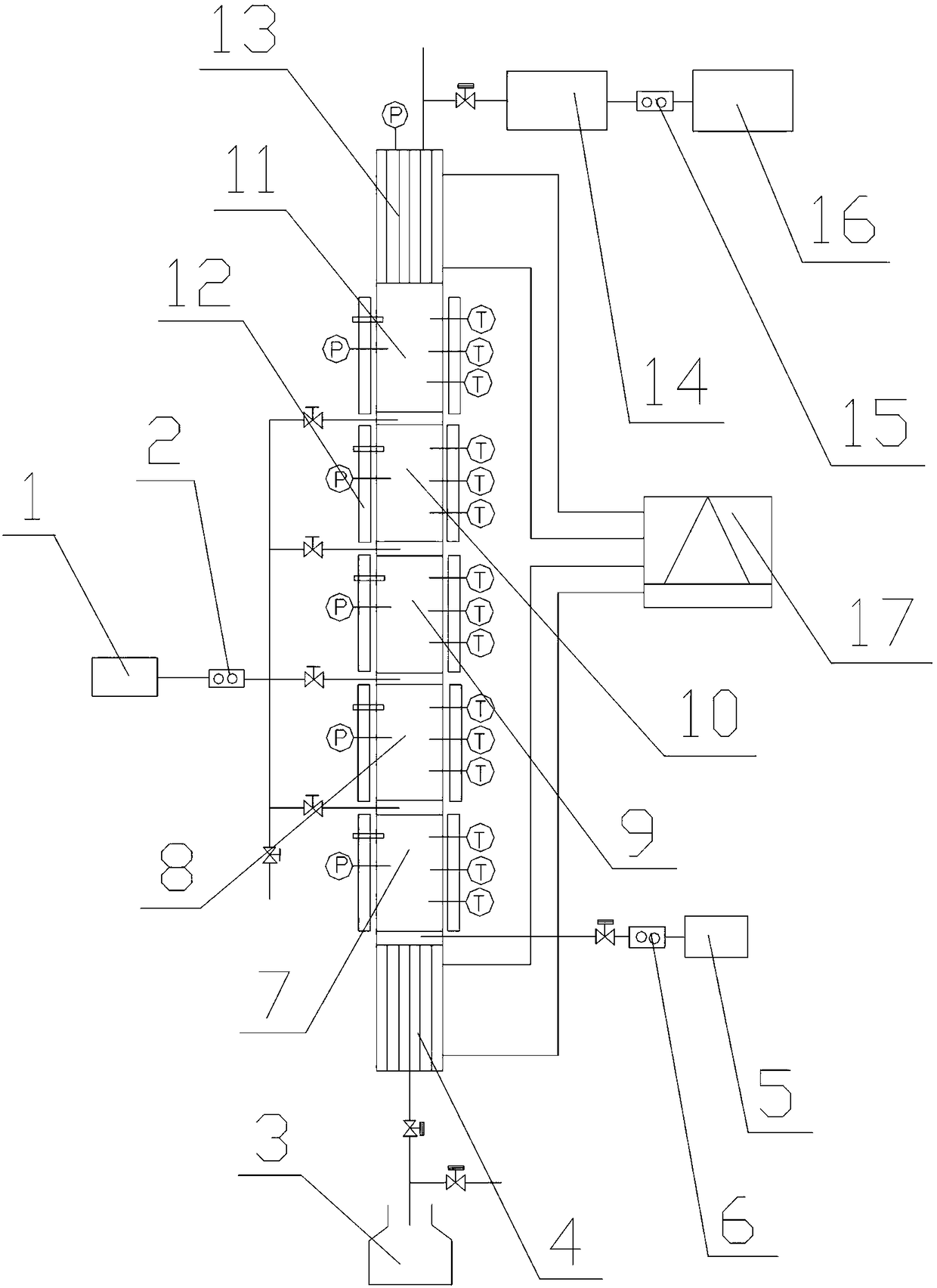

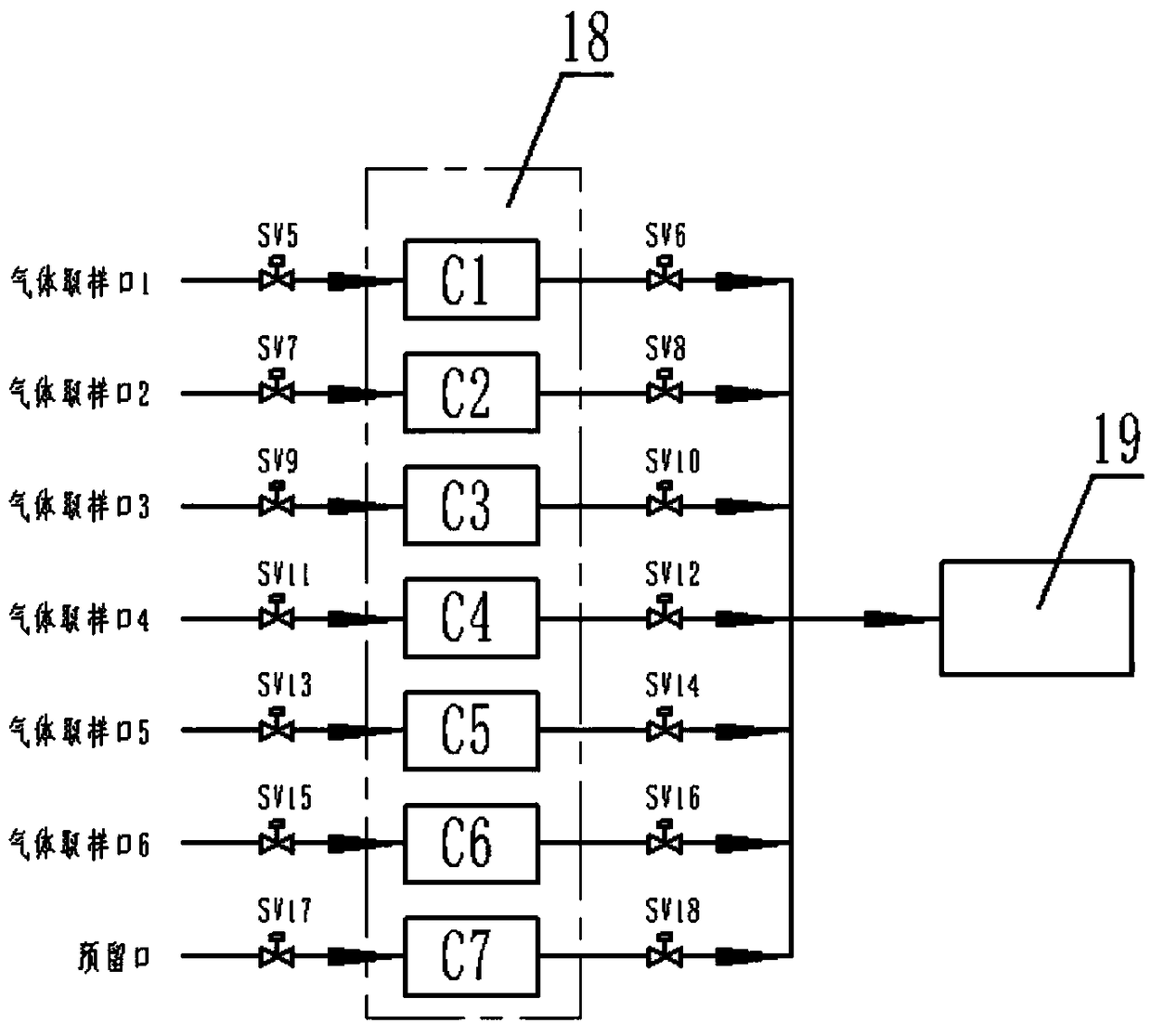

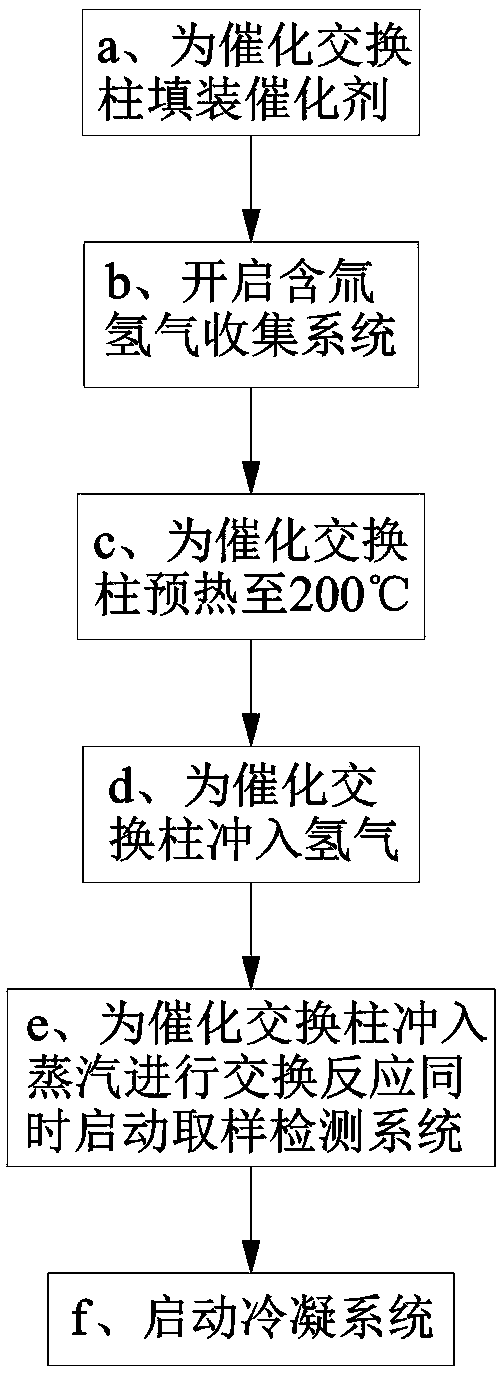

[0040] like Figure 1-3 As shown, a VPCE system that can automatically monitor sampling and analysis includes a first catalytic exchange column, a second catalytic exchange column, a third catalytic exchange column, and a fourth catalytic exchange column that are sequentially connected from bottom to top and filled with hydrophilic catalysts. Catalytic exchange column and fifth catalytic exchange column, tritium-containing water vapor generating device, catalytic hydrogen supply system, condensation system, tritium-containing hydrogen gas collection system, product water collection system, sampling detection system and control system; the first catalytic exchange column , the outer circumference of the second catalytic exchange column, the third catalytic exchange column, the fourth catalytic exchange column and the fifth catalytic exchange column are all provided with a heating insulation layer for auxiliary heating, the first catalytic exchange column, the second catalytic ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com