Structural slab and slab core and machining method of slab core

A processing method and technology for structural panels, which are used in wood processing appliances, joining of wooden veneers, manufacturing tools, etc., can solve the problems of high formaldehyde content, poor sound insulation effect, and small application range, and achieve high rigidity and bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

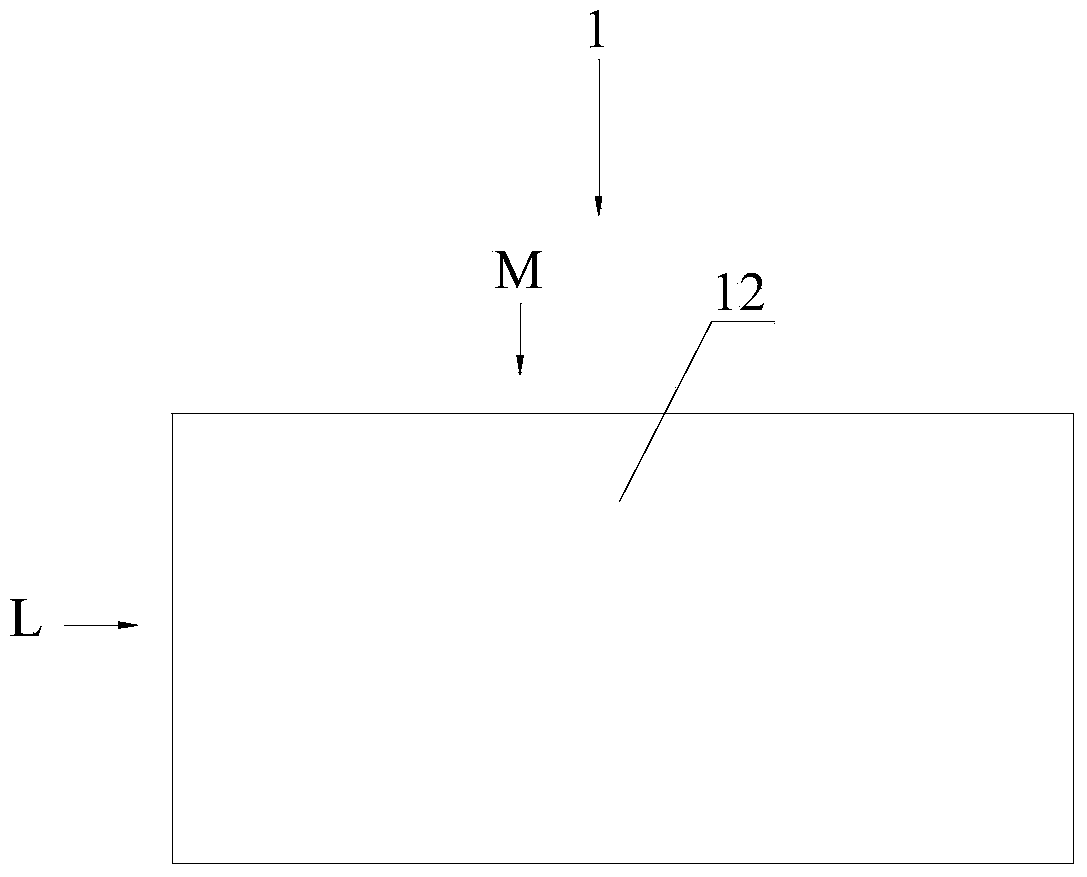

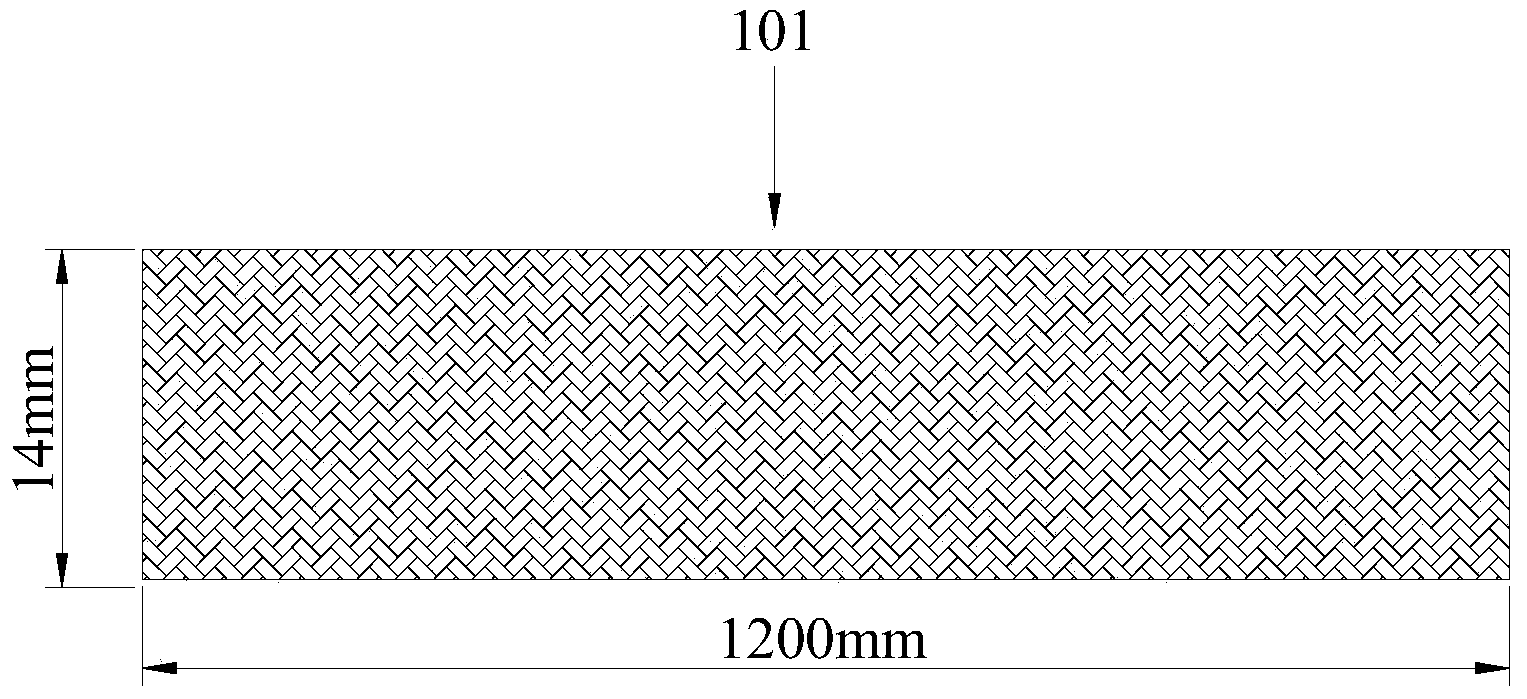

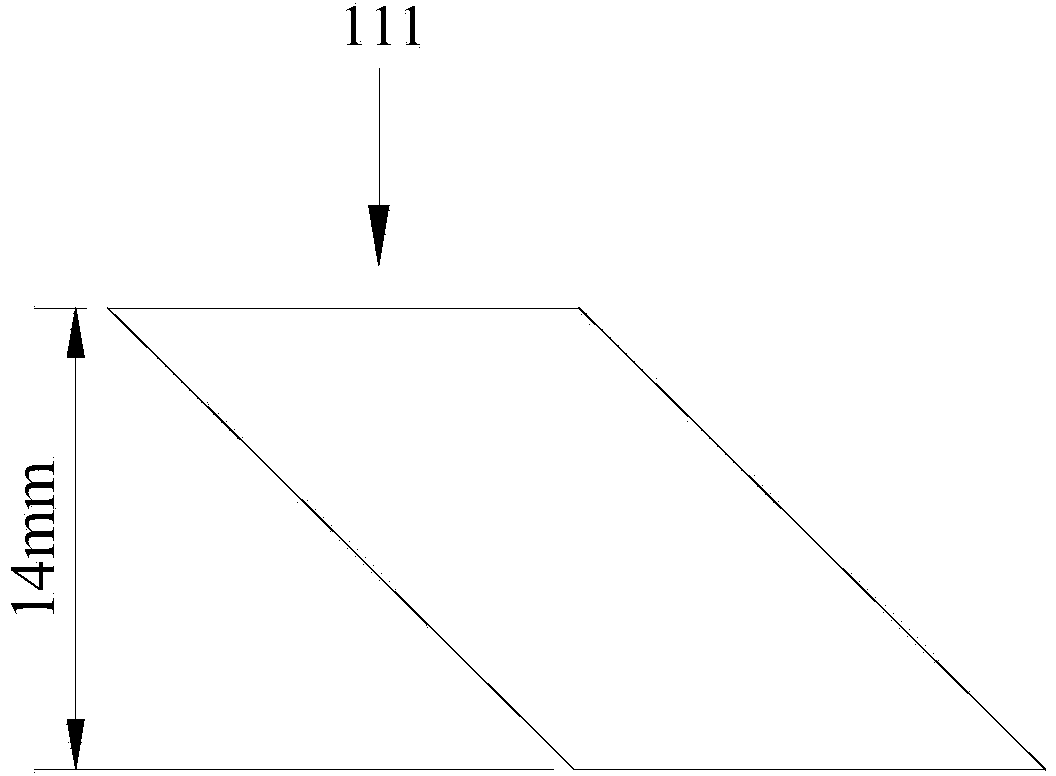

[0070] See Figure 1 to Figure 7 ,in, figure 1 It is a structural schematic diagram of a structural plate plane in a specific embodiment; figure 2 It is a structural schematic diagram of the plates described in the first embodiment; image 3 It is a schematic structural diagram of the first shear sheet described in the first embodiment; Figure 4 It is a structural schematic diagram of the second shear sheet in the first embodiment.

[0071] Compared with the existing technology, this scheme finds another way to optimize the design of the core 11 of the structural plate 1, and adopts the structural form of shear force and frame, so as to effectively improve the structural strength and bearing capacity of the structural plate 1 and reduce the deflection deformation in the application of the plate .

[0072] Specifically, the structural plate 1 includes a plate core 11, and the plate core 11 is provided with multiple sets of structural units 100, and each structural unit 10...

Embodiment 2

[0094] Please also see Figure 11 to Figure 14 ,in, Figure 11 It is a structural schematic diagram of the transverse pressure-bearing strip described in the second embodiment; Figure 12 It is a structural schematic diagram of the vertical pressure-bearing sheet described in the second embodiment; Figure 13 It is a schematic structural diagram of the third shear sheet described in the second embodiment; Figure 14 It is a schematic structural diagram of the fourth shear sheet in the second embodiment.

[0095] In order to clearly show the difference between this solution and the first embodiment, components and structures with the same function are marked with the same reference numerals.

[0096] Compared with the first embodiment, this embodiment has the same main body composition and force-bearing principle. The difference lies in that this solution is designed for the strip form and bonding structure forming the structural unit 100 .

[0097] combine Figure 11 with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com