Automatic deviation adjusting mechanism for welding position of lithium battery cap

A technology of welding position and bias adjustment mechanism, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of safety risks, inability to locate the welding position, welding slag easily falling into the battery, etc. The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

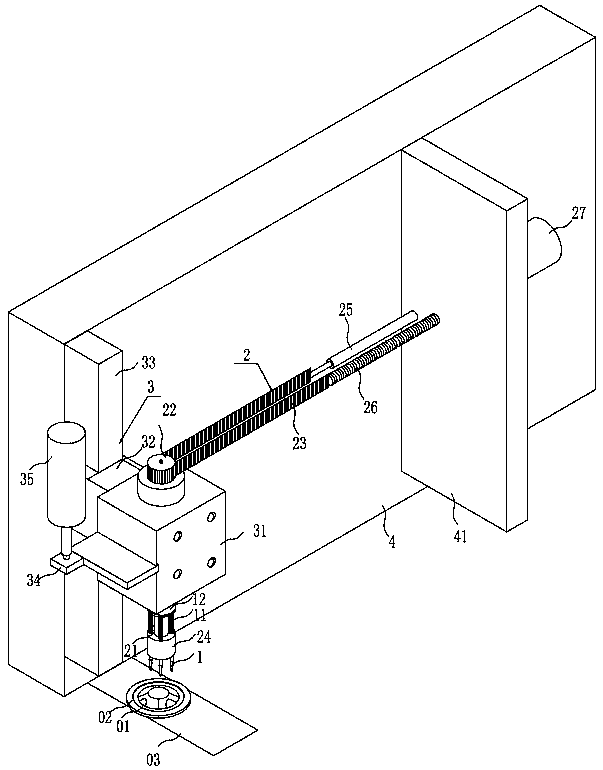

[0016] Such as figure 1 As shown, an automatic deviation adjustment mechanism for the welding position of a lithium battery cap includes at least two positioning probes 1, the positioning probes 1 are connected to the deviation adjustment power structure 2, and the deviation adjustment power structure 2 can drive the positioning probe 1 Turn to adjust the position so that the positioning probe 1 is inserted into the hole 01 of the top cover. In the specific implementation, the top cover hole 01 of the top cover 02 of the battery cap is usually pre-adjusted to a position that coincides with the positioning probe 1, and is transported to the bottom of the positioning probe 1 through the delivery track 03. If the positioning probe 1. When inserted into the top cover hole 01, there is no need to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com