Pipe union fastening structure and its assembling process

A technology for fastening structures and pipe joints, which is applied in the direction of pipes/pipe joints/fittings, sealing surface connections, passing components, etc., can solve the problems of low reliability of pipe joints in direction adjustment, and overcome installation difficulties and reliability problems , the effect of overcoming unreliable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

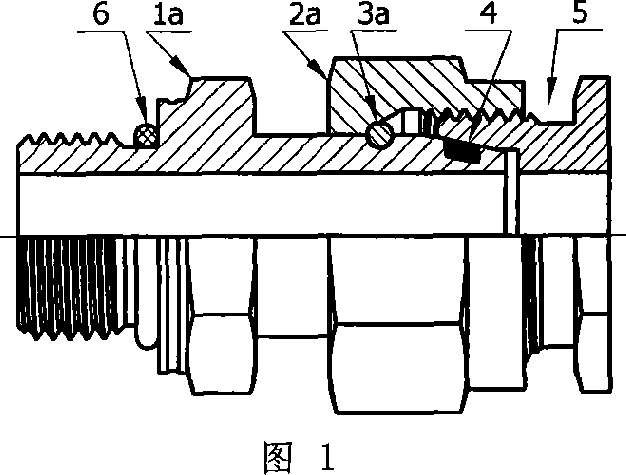

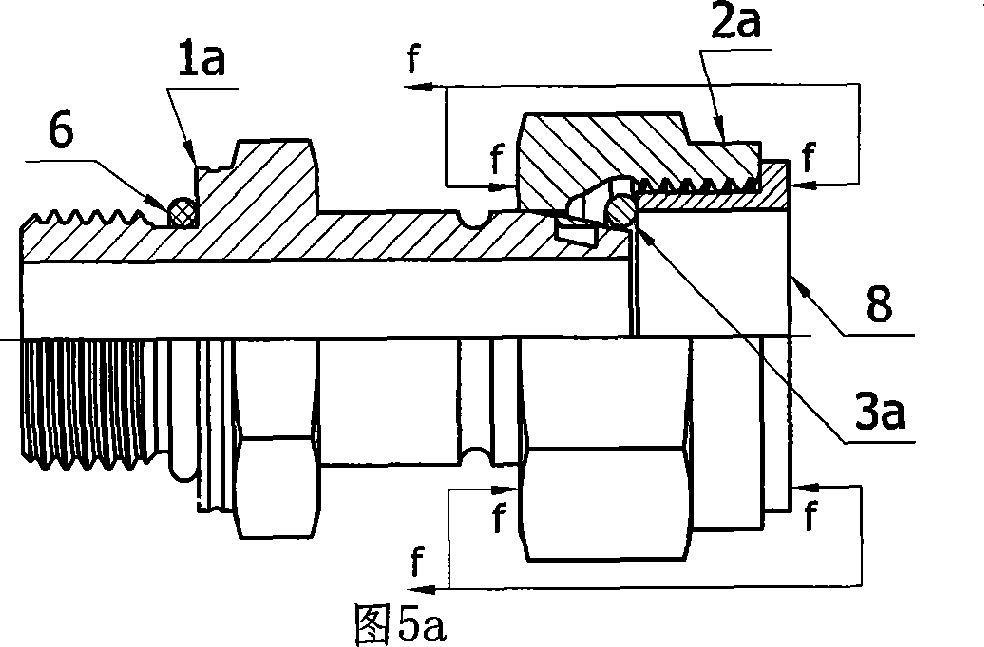

[0017] The pipe joints specified in ISO 8434-1 mainly use the conical structure 5 shown in Figure 6, the drive nut 10 and the extrusion ferrule 11 to realize the connection to the flat-end metal pipe. Therefore, a cone that can be docked with the standard conical structure 5 is provided. The head structure can simply realize the direction-adjusting connection of the non-standard interface relative to the standard cone 5. The pipe joint fastening structure of the present invention is the optimal fastening structure required by the ISO 8434-1 cone mouth / cone head direction adjustment structure.

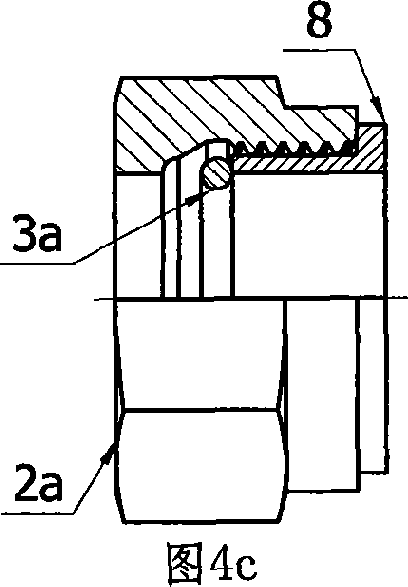

[0018] As shown in Figure 1, the ISO 8434-1 cone / cone head direction adjustment structure is matched with the fastening structure of the present invention, and the direction adjustment connection of the bend, tee and four-way joints with the cone structure 5 and the threaded port can be realized Among them, piece 1a is the joint body, piece 2a is the rotating nut, piece 3a is the open r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com