Ball taking and casting device, paraffin removal ball casting machine for oil transmission pipeline and ball casting method

A technology of wax removal and ball-throwing device for oil pipelines, which is applied in cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc. It can solve the problems of oil pipeline blockage, cumbersome operation, lame pressure, etc., and achieve the effect of structural realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

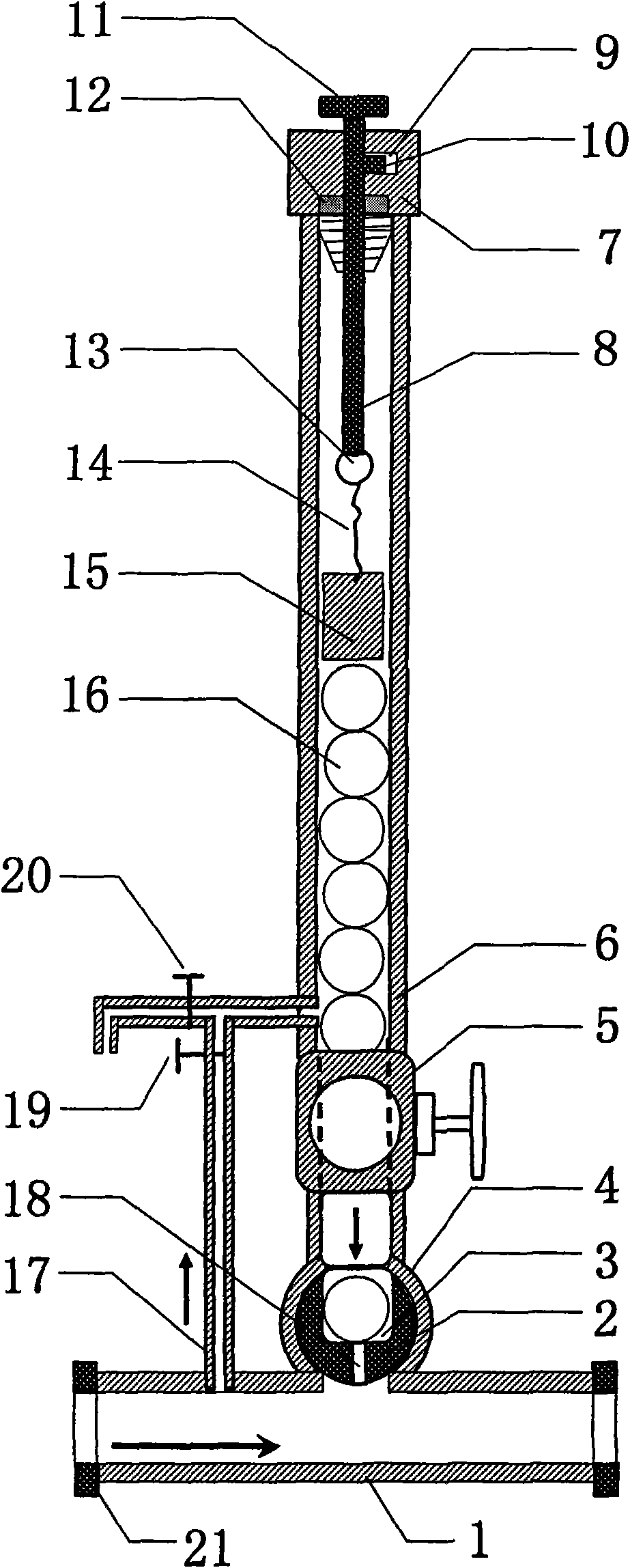

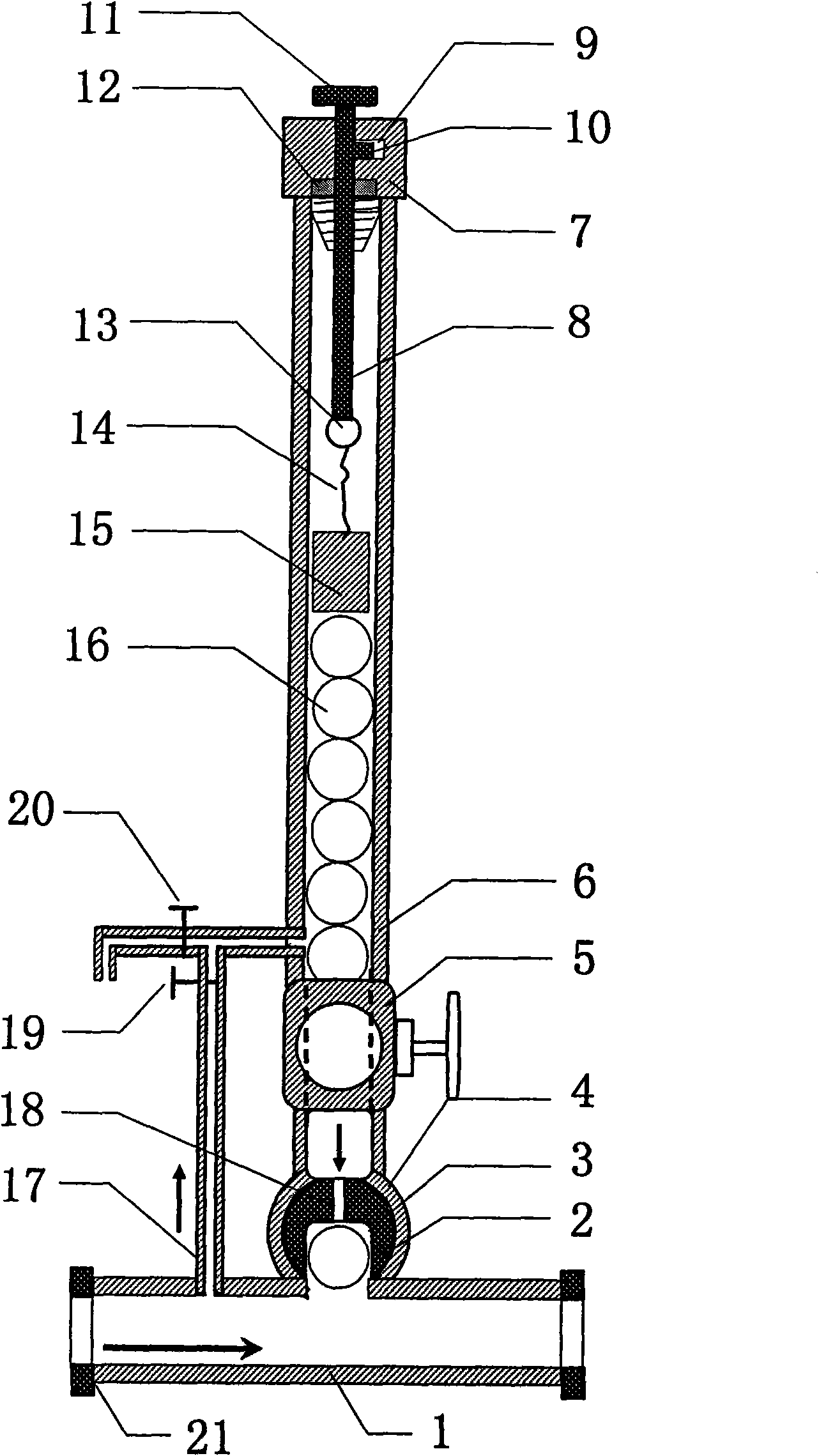

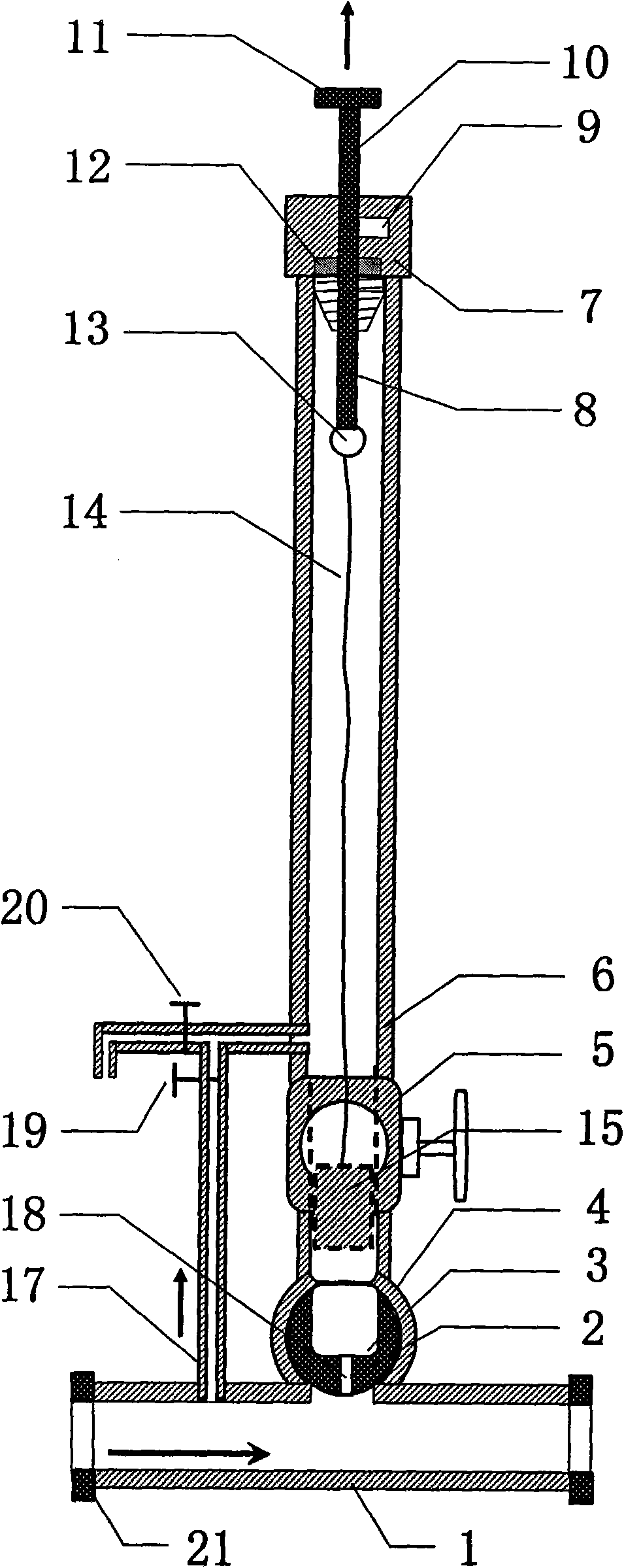

[0037] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of a preferred embodiment of the oil pipeline wax removal and ball throwing machine of the present invention. The oil pipeline wax removal ball throwing machine includes pressure balance pipes 17 arranged in sequence along the oil delivery direction and communicated with the oil delivery pipeline 1 respectively and a ball taking and throwing device The ball-taking device comprises a ball storage tube 6, a ball-storage rotor shell 4 and a ball-storage rotor 2 that rotates in the ball-storage rotor shell 4. The top of the ball-storage tube 6 is sealed by a plug 7, and the bottom of the ball-storage tube 6 is sealed. It is fixedly connected and communicated with the upper end of the ball-taking rotor housing 4, and the lower end of the ball-taking rotor housing 4 is fixedly connected and communicated with the oil pipeline 1. Diameter, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com