Counter-force structure of static load test and static load test system

A static load test and connection structure technology, which is applied in the direction of basic structure engineering, basic structure test, construction, etc., can solve the problems of inapplicability and safety of the static load test reaction force structure, and achieve flexible layout, good safety and easy installation. The effect of convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

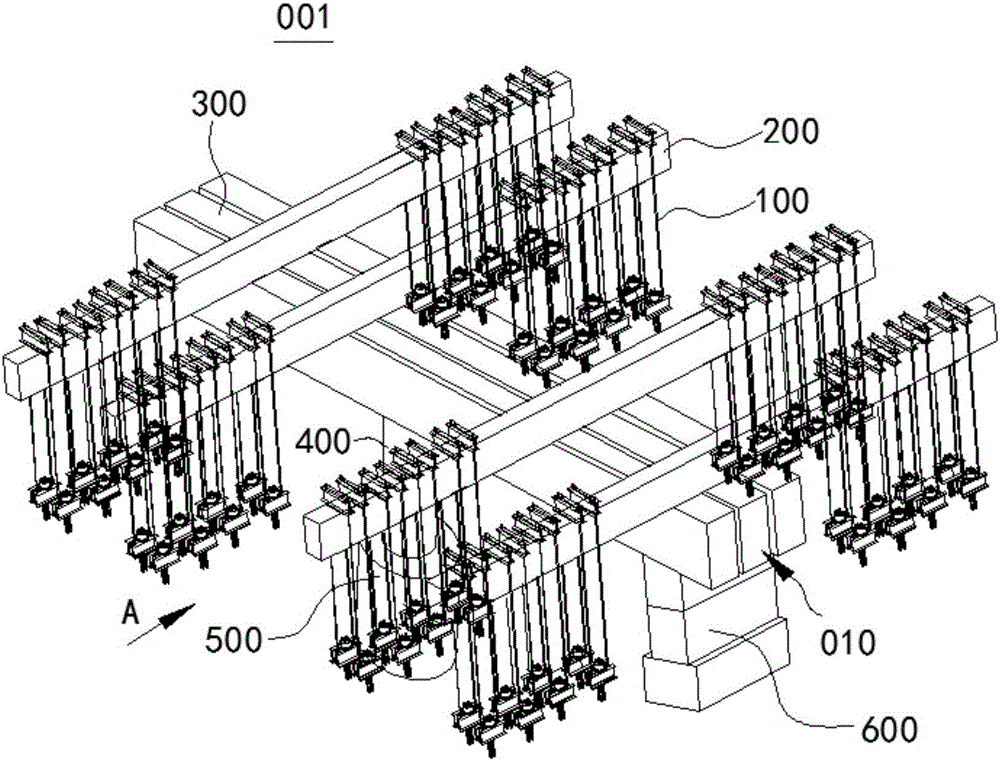

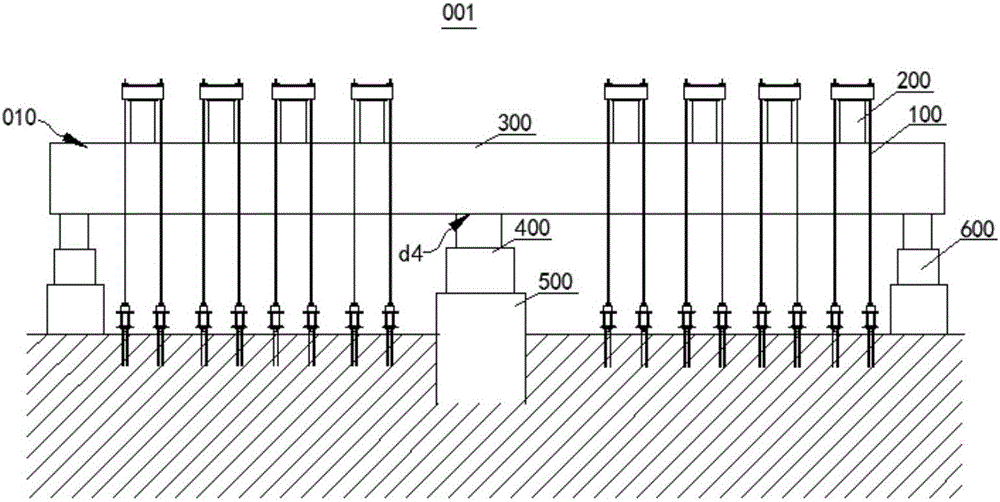

[0060] figure 1 is a schematic structural view of the static load test system 001 in the embodiment of the present invention; figure 2 yes figure 1 A view from direction A. Please refer to figure 1 , figure 2 , the static load test system 001 in this embodiment includes a test pile 500 and a static load test reaction force structure 010 for providing a reaction force to the test pile 500 .

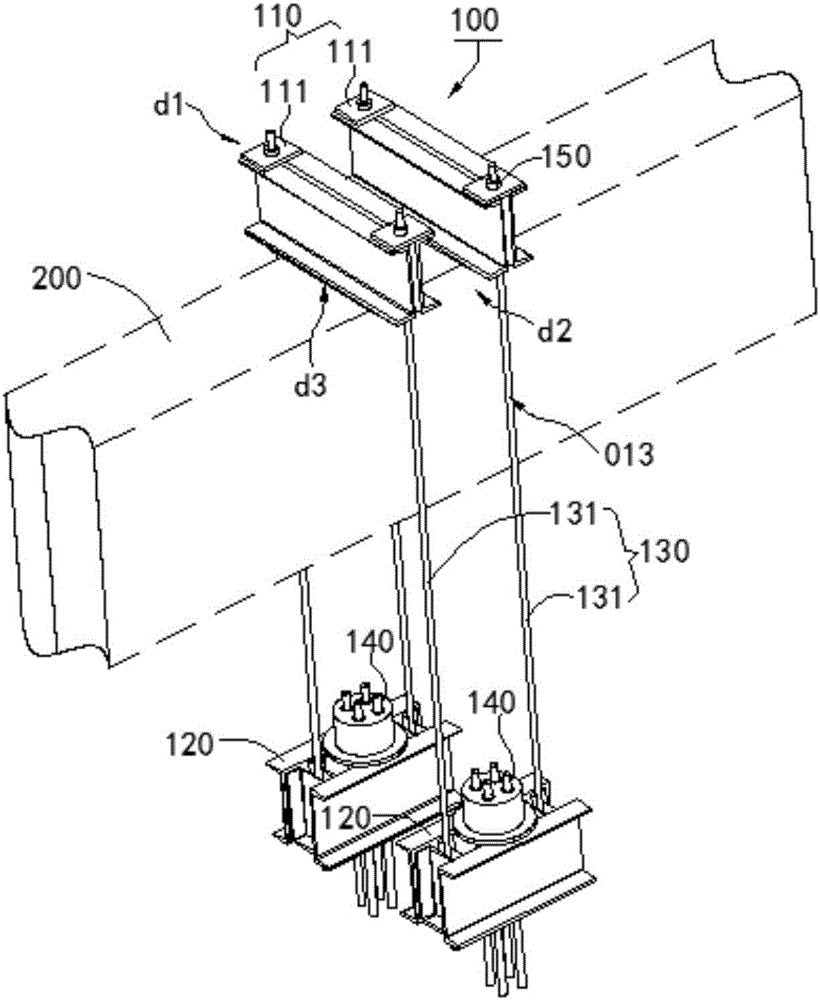

[0061] Among them, the static load test reaction force structure 010 includes a jack 400, a main beam 300 supported on the upper end of the jack 400, a number of secondary beams 200 respectively pressed on the two ends of the upper end surface of the main beam 300, and a plurality of secondary beams 200 along the length of each secondary beam 200. The anchor rod connection structures 100 are distributed in directions and located on both sides of the main beam 300 .

[0062] The upper end of the bolt connection structure 100 is connected to the secondary beam 200 , and the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com