Inorganic reinforced fiberglass pipe jacking and molding process

A technology of inorganic reinforcement and glass fiber reinforced plastics, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of limited resources, high resistance, water resistance, etc., and achieve the effect of smooth inner surface, long service life and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

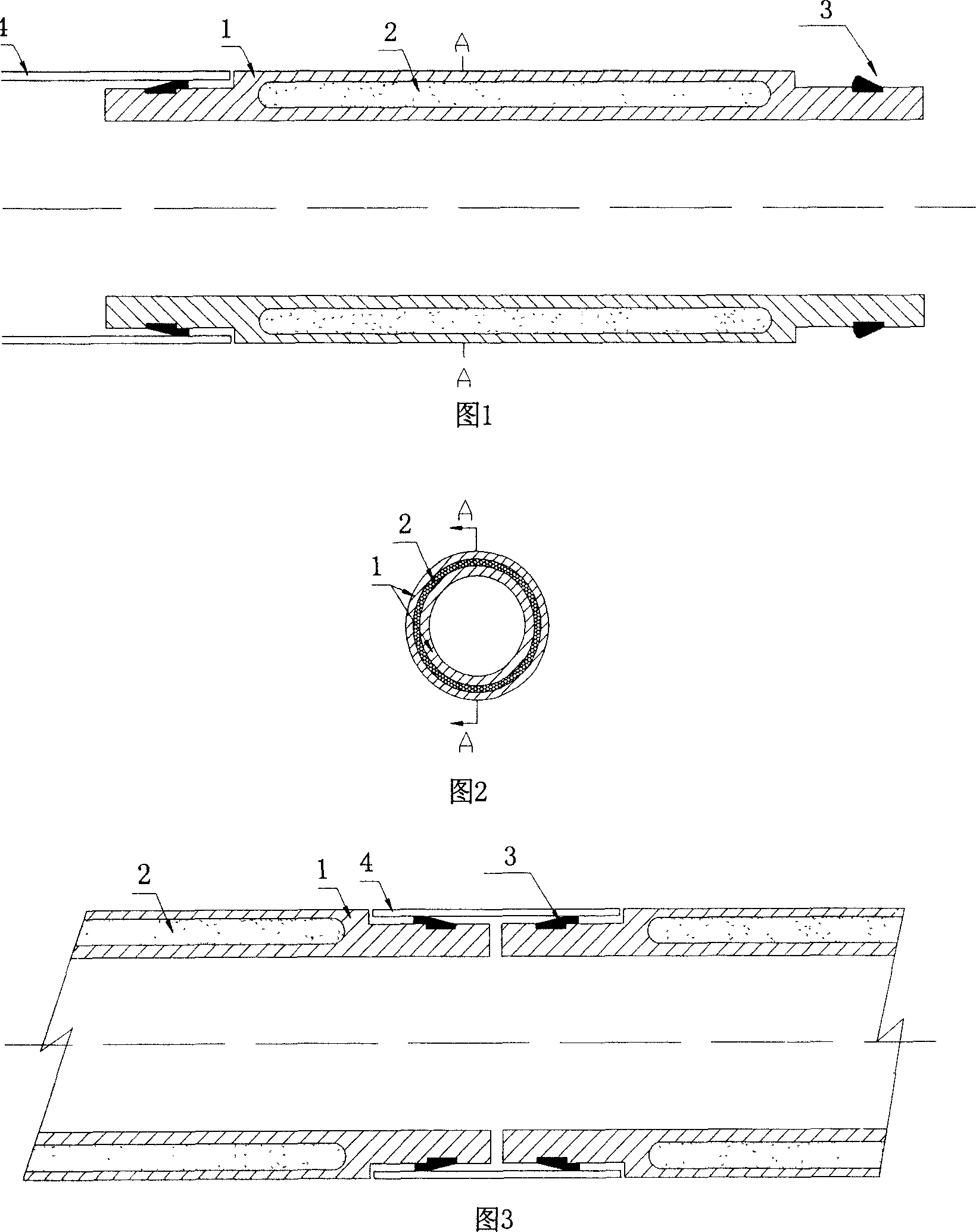

[0010] The manufacturing process of inorganic reinforced FRP jacking pipe:

[0011] Organic inner surface production: impregnate glass fiber surface felt and knitted felt with unsaturated polyester resin, wrap it on the surface of the mandrel, squeeze it with mesh cloth, and drive away air bubbles. A high-resin-content waterproof inner liner is formed, which is then wrapped with dry fiberglass cloth.

[0012] Intermediate inorganic structure layer: The inorganic materials (magnesium chloride, magnesium oxide, ferrous sulfate, calcium sulfate, calcium dihydrogen phosphate, fly ash mixed glue) are proportioned, coated on the surface layer, and scraped with a scraper Flattened, then wrapped with fiberglass cloth or reinforced with continuous fiber winding. Repeat the operation until the appropriate thickness is reached. The thickness of a single production is determined according to the size of the pipe diameter and the requirements of the pressure level and rigidity level.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com