High-ductility waterproof anti-crack composite mortar as well as mixing method and construction process thereof

A composite mortar with high ductility, applied in construction, building construction, covering/lining, etc., can solve the problems of reduced mechanical properties and durability, poor strength and durability, and short operating time, and achieve improvement Effects of strength, improved compactness, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the quality ratio of the raw materials in Table 1, the mortar is mixed with the following methods:

[0028] (1) Take cement, fly ash, mineral powder, lime powder, silica fume, primary admixture, redispersible latex powder, waterproofing agent, hydroxypropyl methylcellulose, epoxy emulsion, curing agent, expansion Put the polyvinyl alcohol powder and water reducing agent into the mixer and stir for 30s at the speed of 45~70r / min, then add the quartz sand and continue to stir for 30s at the same speed;

[0029] (2) Then add water and stir at the same speed for 3 to 5 minutes, and finally add polyvinyl alcohol fiber, stir for 3 to 5 minutes to obtain a high ductility waterproof and crack resistant composite mortar.

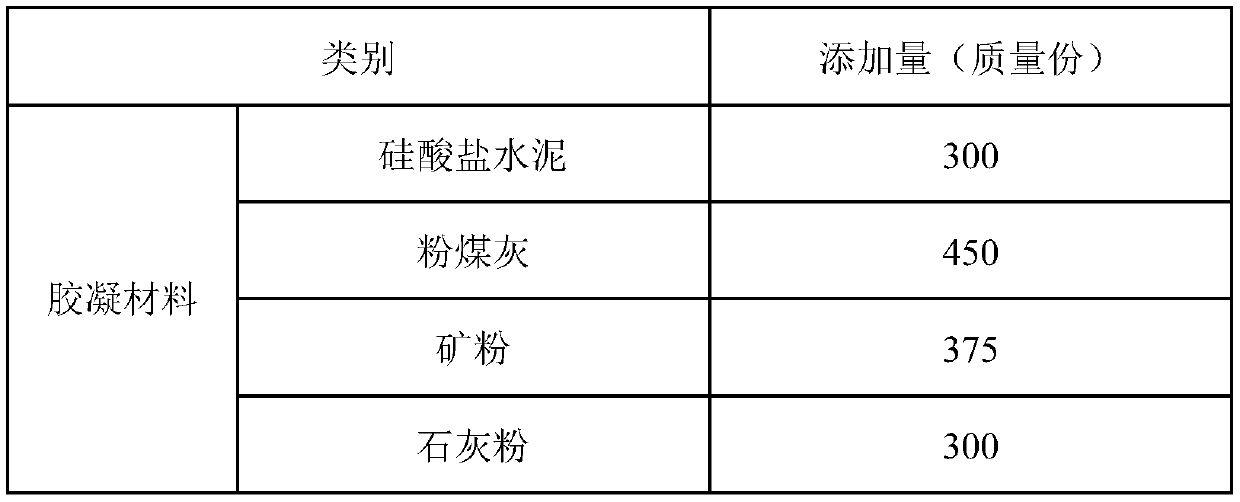

[0030] Table 1 Formulation table of high ductility waterproof and anti-crack composite mortar (unit: Kg / m 3 )

[0031]

[0032]

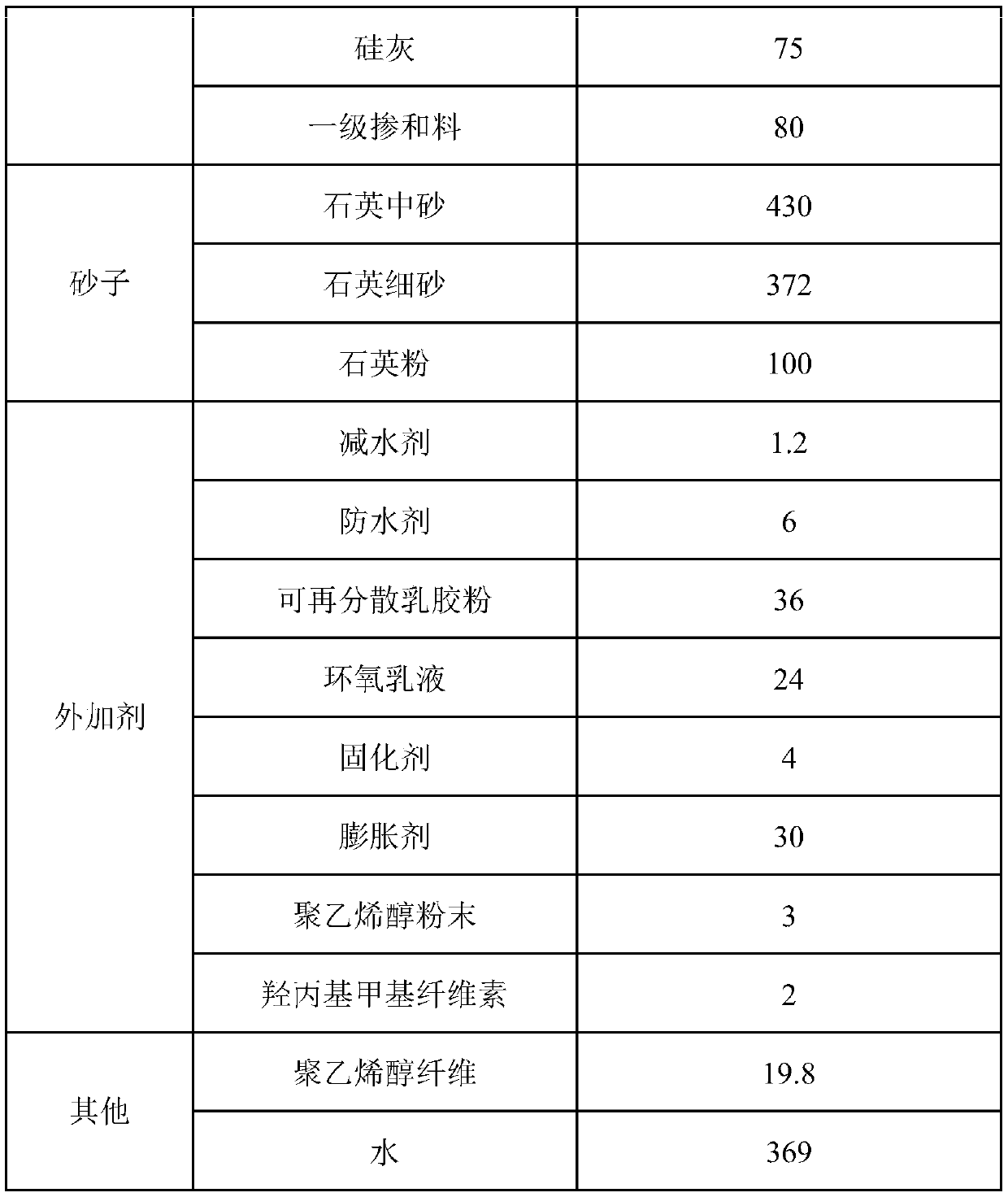

[0033] Table 2 shows the test results of toughness, waterproof and crack resistance performance and strength performance of t...

Embodiment 2

[0051] Prepare the mortar according to the raw materials shown in Table 6.

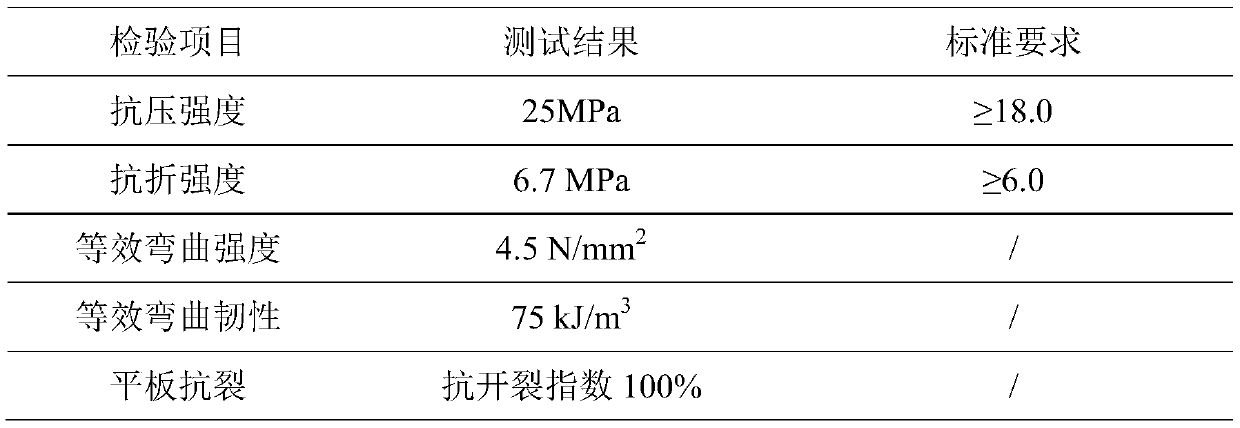

[0052] Table 6

[0053]

[0054]

[0055] Table 7 shows the test of toughness, waterproof and crack resistance performance and strength performance of the mortar in this embodiment.

[0056] Table 7

[0057]

[0058]

Embodiment 3

[0060] Prepare the mortar according to the formula shown in Table 8.

[0061] Table 8 (Unit: Kg / m 3 )

[0062]

[0063]

[0064] The related performance test results of the mortar prepared in this embodiment are shown in Table 9.

[0065] Table 9

[0066]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com