Concrete member and steel support H-shaped embedded connection joint

A technology for connecting nodes and concrete, which is applied in the direction of building structure and construction, can solve the problems of small node bearing capacity, easy cracking of concrete, and low bearing capacity of connecting nodes, so as to improve the seismic performance and hysteretic performance, and solve the problem of concrete being easy to crack. Cracking, the effect of improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical content of the present invention is further described below in conjunction with accompanying drawing and embodiment:

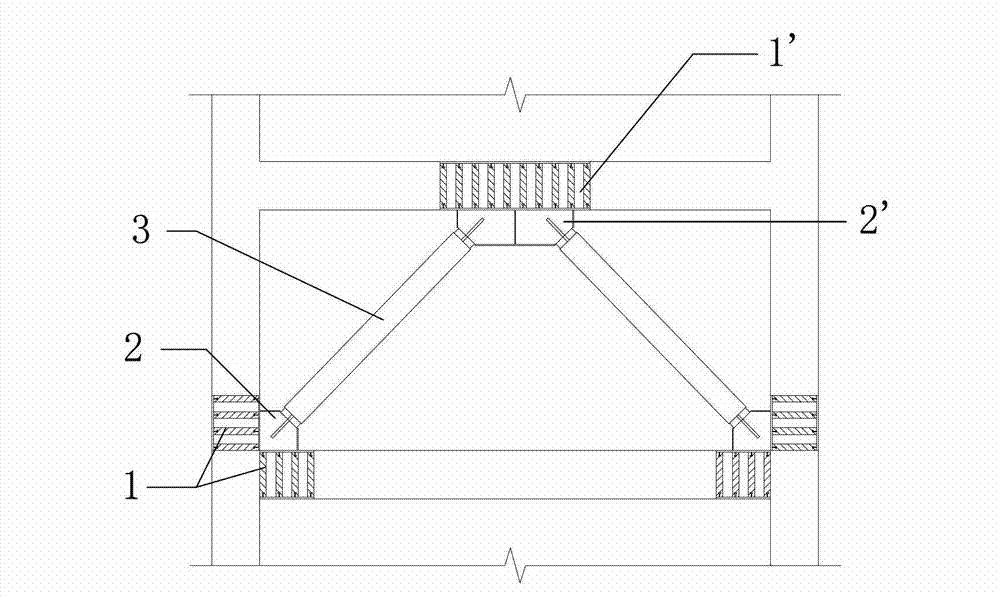

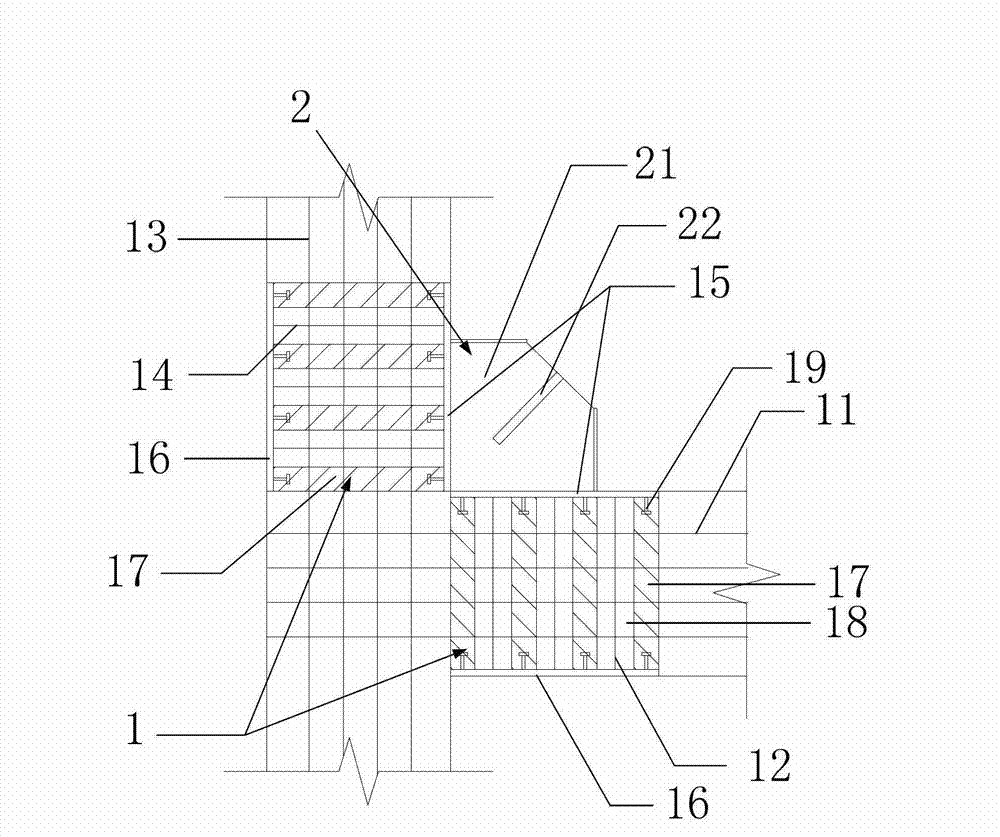

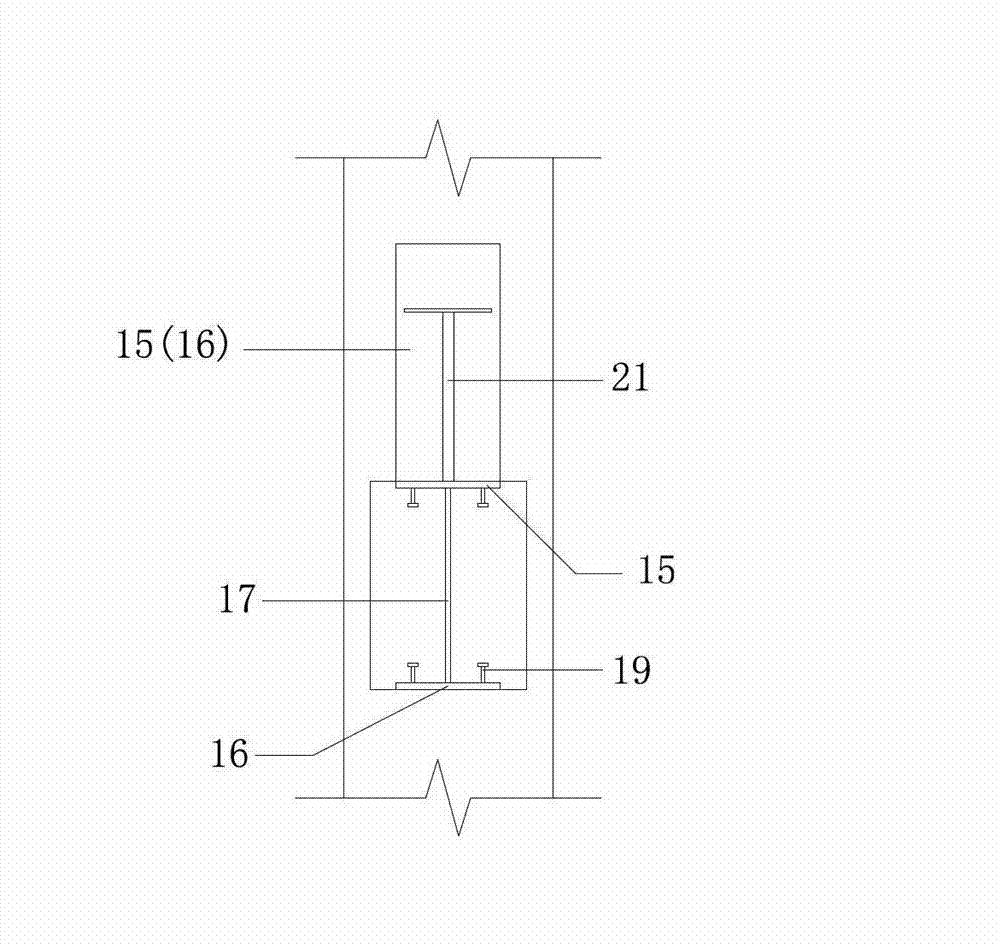

[0042] figure 1According to the first embodiment of the present invention, a schematic diagram of the connection structure between the concrete member and the steel support H-shaped embedded connection node is shown. The concrete member and the steel support H-type pre-embedded connection node are set in the area surrounded by two beams (upper beam and lower beam) and two columns, which mainly include concrete member parts 1 and 1', connection node parts 2 and 2' and steel support 3. Specifically, in figure 1 In the preferred example shown, the concrete member part 1 is arranged at the connection node of the lower beam and the column, and is located in the beam as well as in the column. The concrete member part 1' is arranged at the span of the upper beam and is located inside the beam. The connection node part 2 is connected with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com