Concrete arc rib construction method

A construction method and concrete technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of high risk, long time, poor lateral stability, etc., to avoid the problem of arch rib deformation, improve construction efficiency, and solve easy cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

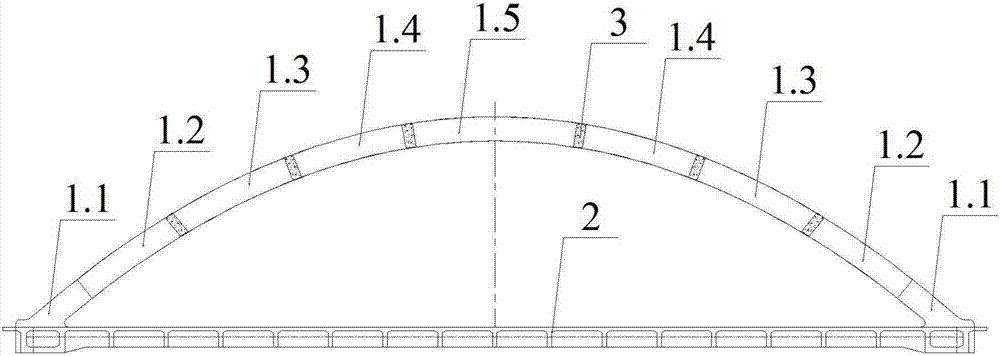

[0020] Such as figure 1 In this embodiment, by dividing the arch rib 1 into a plurality of segments and constructing each segment separately, the problems of linear change and arch foot cracking caused by stress dissipation during the construction of the arch rib 1 are avoided.

[0021] In this embodiment, the arch rib 1 is divided into an arch foot segment 1.1 and an arch top segment 1.5, wherein at least one arch rib segment is included between the arch foot segment 1.1 and the arch top segment 1.5, such as figure 1 As shown, three arch rib segments are taken as an example for illustration. From below there are at least a first segment 1.2, a second segment 1.3 and a third segment 1.4 respectively, and three other segments are arranged symmetrically on the other side.

[0022] There is a separation groove 3 between the adjacent ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com