External mould assembly for cold-drawing pipes

A technology of mold components and pipes, which is applied in the direction of wire drawing dies, etc., can solve the problems of high scrap rate, difficult inner hole of pipes, changes in wall thickness and size, and large bending degree, so as to increase the cost of molds and eliminate the effect of sharp diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

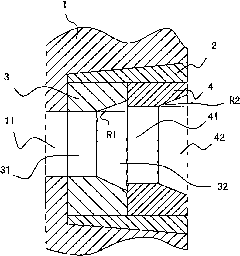

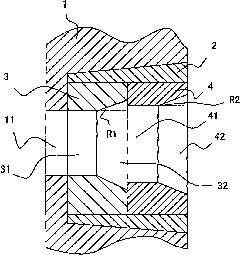

[0012] see figure 1 . Die base 1 is fixed on the frame. The ring wall of the outer mold receiving cavity of the mold base 1 is a tapered ring wall from the back to the front, and the front mold 3 and the rear mold 4 are accommodated in the outer mold receiving cavity. In order to ensure the firmness and concentricity of the front mold 3 and the rear mold 4, the positioning wedge 2 is embedded between the tapered ring wall and the outer wall of the front mold 3 and the rear mold 4, so that the front mold 3 and the rear mold 4 are tightly It is firmly combined into one body and accommodated in the receiving cavity of the outer mold. From ensuring the firmness and concentricity purpose of front mold 3 and back mold 4, can realize by the means of different changes, for example: the outer wall of front mold 3 and back mold 4 can be cylindrical, also can be taper, they As long as it matches the inner hole wall of the positioning wedge 2, it is even possible to add some concave-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com