Wall structure for external thermal-insulating rock wool wall and construction method thereof

A technology of external thermal insulation and rock wool, which is applied in the direction of thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of reducing the durability and fire resistance of rock wool, its own weight, and prone to hollowing cracks, etc., so as to prevent the deformation of rock wool boards , Prevent hollowing cracks and falling off, solve the effect of easy cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

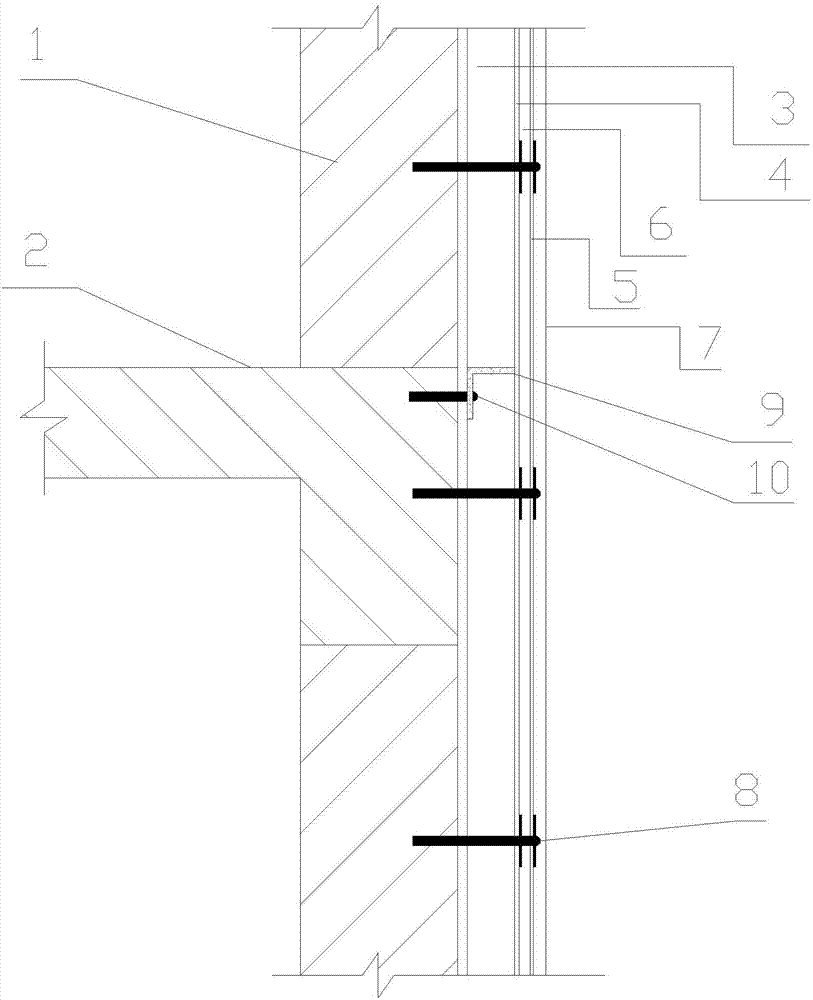

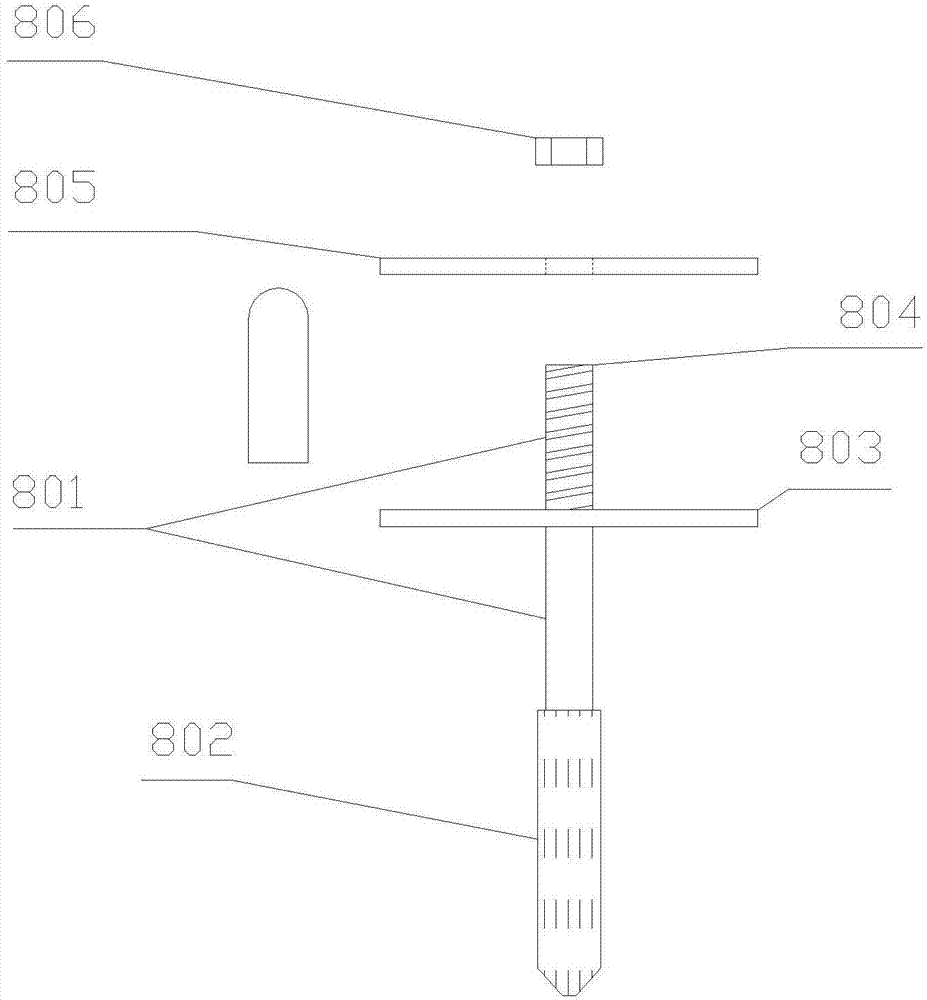

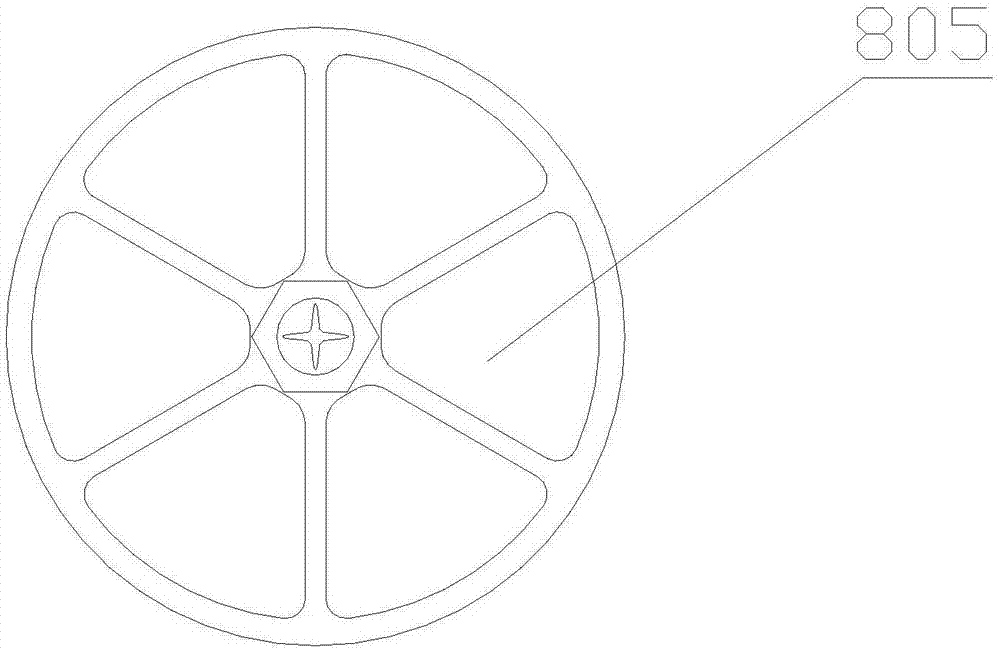

[0018] A wall structure for rock wool external thermal insulation walls, which includes a base wall 1, a reinforced concrete floor 2 at the center of the base wall 1; a rock wool board structure 3 is provided above the base wall 1 A steel wire mesh structure 4 is provided above the rock wool board structure 3 to prevent deformation of the rock wool board structure, and the steel wire mesh structure 4 is also used as the main skeleton of the plastering layer, which can effectively prevent large cracks in the plastering layer;

[0019] Between the described steel mesh structure and the alkali-resistant glass fiber mesh cloth 5 is a middle gray structure 6 made of anti-crack cement mortar, and the outer side of the alkali-resistant glass fiber mesh cloth 5 is provided with an anti-crack cement mortar. The surface layer ash structure 7, the middle layer ash structure 6 and the surface layer ash structure 7 made of anti-cracking cement mortar prevent hollowing cracks in the plasteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com