Method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry

A technology of nano-alumina and semi-solid slurry, which is applied in the field of preparation of semi-solid slurry for aluminum-based composite materials, can solve the problems of complex process, low content, and limited molding, and achieve low process cost, uniform distribution, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

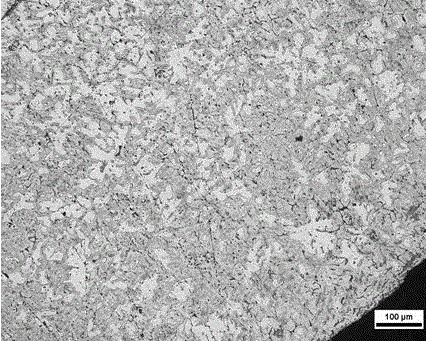

Image

Examples

Embodiment 1

[0012] Firstly, nano-alumina (100nm) was ultrasonically treated in absolute ethanol for 20 minutes, left to stand to remove absolute ethanol, dried at 150-200°C, and calcined at 550°C for 3 hours. The calcined nano-alumina is added with magnesium powder (75 μm) and ball-milled for 30 minutes, wherein the mass ratio of nano-alumina to magnesium powder is 1:7, and the ball-milling speed is 100 rpm; the A356 aluminum alloy is put into a crucible for heating and melting, at temperature At 700°C, the amount of nano-alumina added is 0.5wt.% of the aluminum alloy melt, and the above-mentioned mixed powder of nano-alumina and magnesium powder is added to the aluminum alloy melt at a rate of 0.2g / min , Introduce high-energy ultrasonic waves into the aluminum alloy melt during the addition process, ultrasonic frequency 10KHz, power 1000W, and then continue ultrasonic treatment for 5 minutes, ultrasonic frequency 20KHz, power 1000W; pour the melt into a crucible preheated at 600 °C, Cont...

Embodiment 2

[0014] Firstly, nano-alumina (100nm) was ultrasonically treated in absolute ethanol for 20min, left to stand to remove absolute ethanol, dried at 200°C, and calcined at 550°C for 3h. The calcined nano-alumina is added with magnesium powder (75 μm) and ball-milled for 60 minutes, wherein the mass ratio of nano-alumina and magnesium powder is 1:1, and the ball-milling speed is 100 rpm; the 7075 aluminum alloy is put into a crucible for heating and melting, at a temperature At 700°C, the amount of nano-alumina added is 1.5wt.% of the aluminum alloy melt, and the above-mentioned mixed powder of nano-alumina and magnesium powder is added to the aluminum alloy melt at a rate of 0.2g / min , Introduce high-energy ultrasonic waves into the aluminum alloy melt during the addition process, ultrasonic frequency 10KHz, power 1000W, and then continue ultrasonic treatment for 10min, ultrasonic frequency 20KHz, power 1000W; pour the melt into the crucible preheated at 650 °C, Control the tempe...

Embodiment 3

[0016] Firstly, nano-alumina (30nm) was ultrasonically treated in absolute ethanol for 25 minutes, then allowed to stand to remove absolute ethanol, dried at 200°C, and calcined at 550°C for 4 hours. The calcined nano-alumina was added with magnesium (58 μm) and ball-milled for 60 minutes, wherein the mass ratio of nano-alumina to magnesium powder was 3:7, and the ball-milling speed was 100 rpm; the 2017 aluminum alloy was heated and melted in a crucible, at a temperature of 800 At ℃, according to the addition of nano-alumina in an amount of 1.5wt.% of the aluminum alloy melt, the mixed powder of the above-mentioned nano-alumina and magnesium powder is added to the aluminum alloy melt at a speed of 0.3g / min. In the process of adding high-energy ultrasonic waves into the aluminum alloy melt, the ultrasonic frequency is 8KHz, the power is 1000W, and then the ultrasonic treatment is continued for 10 minutes, the ultrasonic frequency is 20KHz, and the power is 800W; the melt is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com