High-temperature gradient directional solidification conical graphite induction heater

An induction heater, directional solidification technology, applied in induction heating, furnaces without annular cores, coil devices, etc., can solve problems such as low temperature gradient and limited mechanical properties of samples, achieve temperature gradient improvement, and improve material synthesis. performance, the effect of improving the structure of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

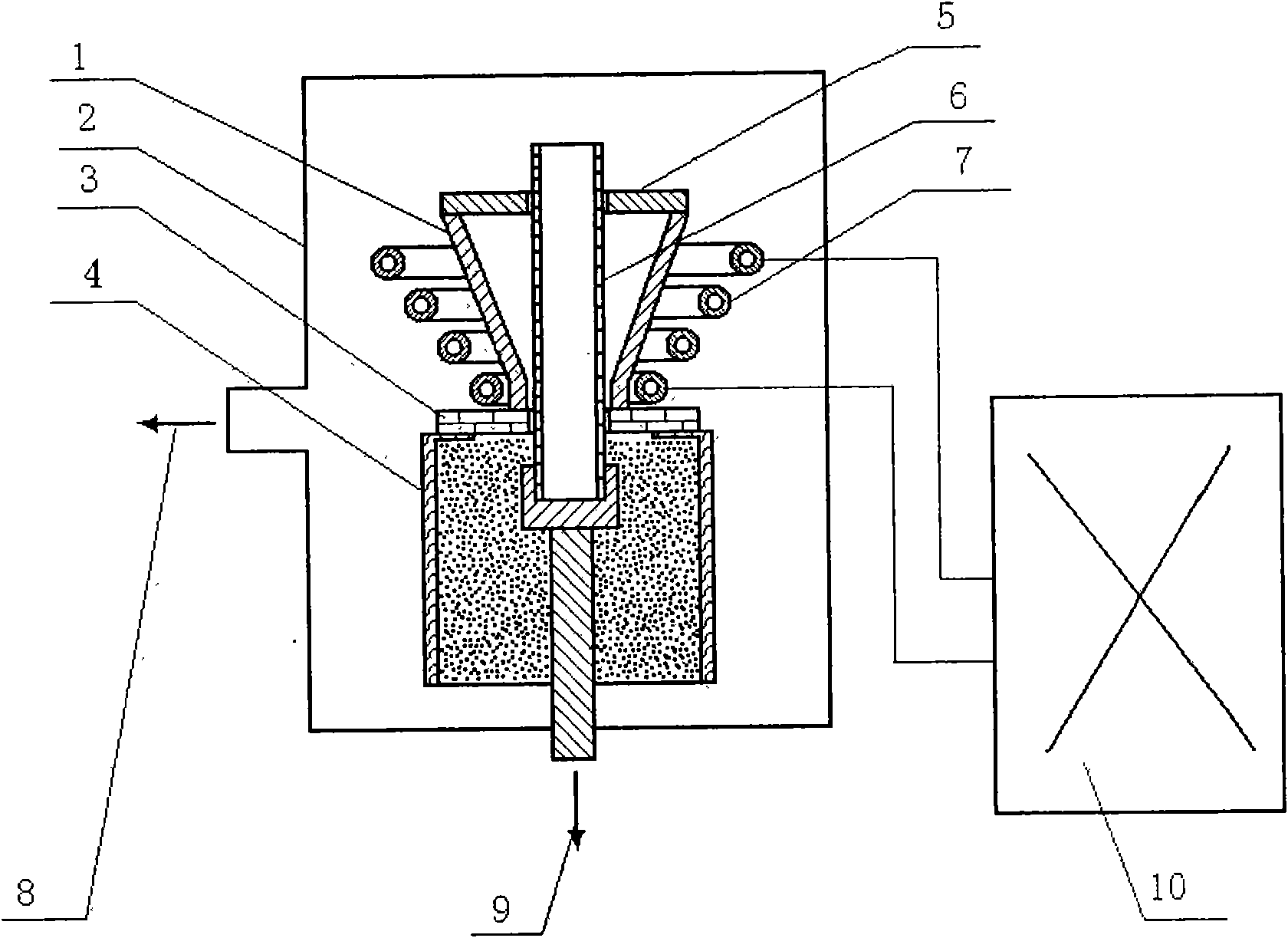

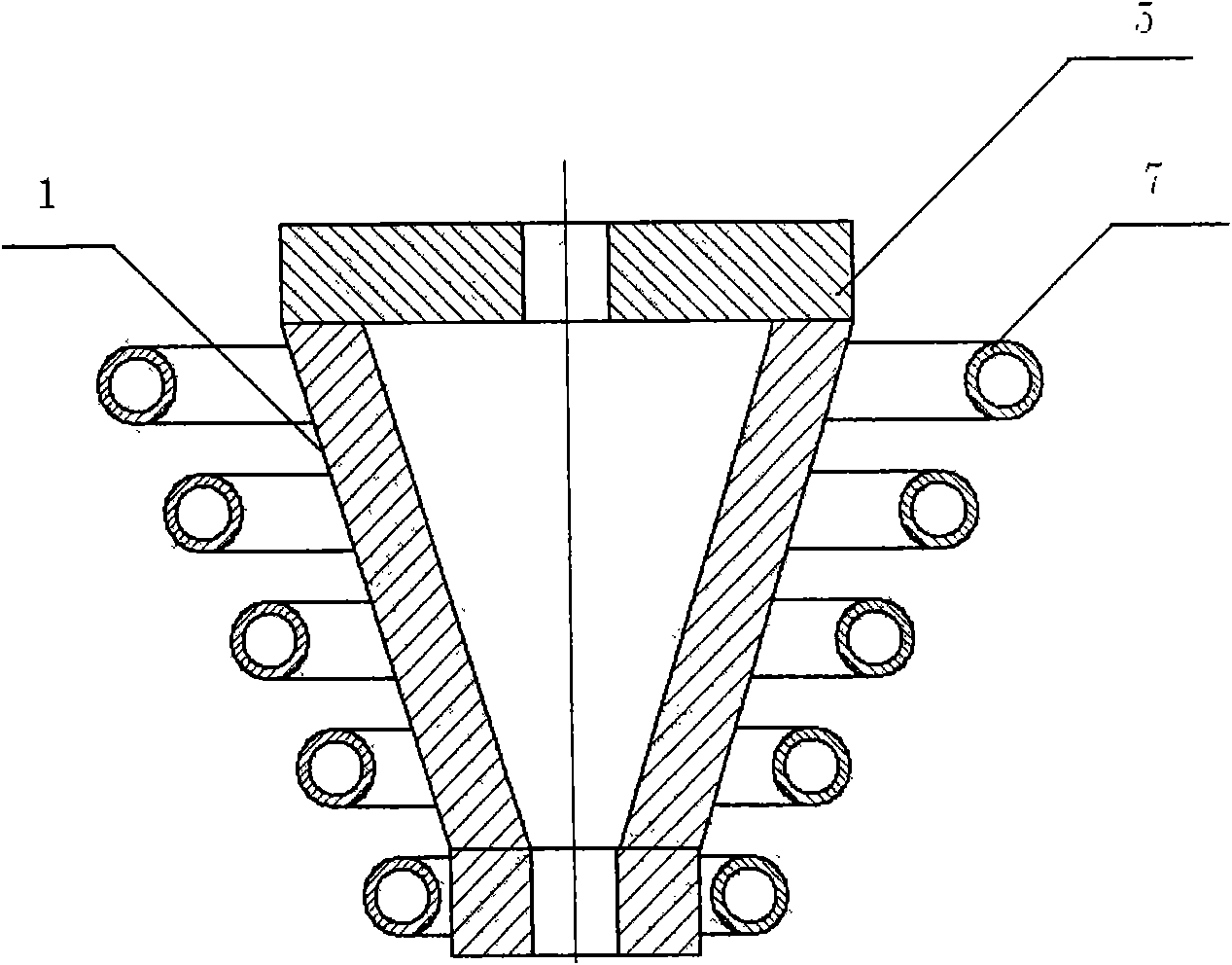

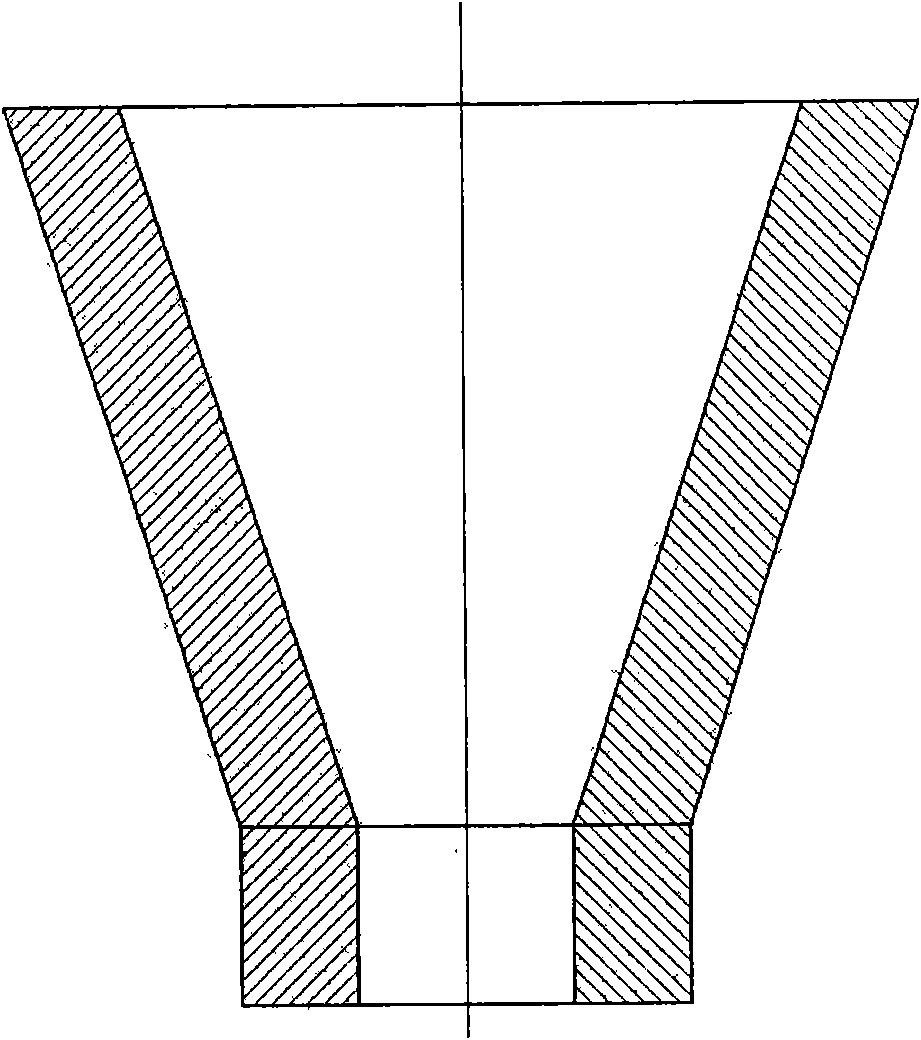

[0019] This embodiment includes furnace body 1, drawing system 9, crystallizer 4, crucible 6 and graphite induction heater, wherein: graphite induction heater is made of high-frequency induction coil 7, graphite heating element 1 and graphite heating element made of graphite The upper cover 5 is composed of the upper cover 5; the graphite heating element 1 is hollow conical, and the high-frequency induction coil 7 is also correspondingly conical, and the graphite heating element 1 is located in the high-frequency induction coil 7, and the small end of the high-frequency induction coil 7 is connected to the The small end of the graphite heating element 1 is heated by concentrated induction, and the small end of the graphite heating element 1 is then intensively radiated and heated to the crucible 6; the large end of the high-frequency induction coil 7 and the large end of the graphite heating element 1 preheat the crucible 6 ; The upper cover 5 is located at the large diameter e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com