Method for preparing nano-alumina reinforced aluminum-based composite semi-solid slurry based on composite vibration technology

A technology of nano-alumina and semi-solid slurry, which is applied in the field of preparation of semi-solid slurry for aluminum-based composite materials. The effect of low and fine distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

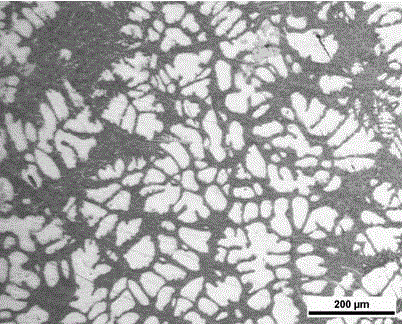

Image

Examples

Embodiment 1

[0016] (1) Mix nano-alumina (100nm) and aluminum powder (75μm) for 45h, wherein the mass ratio of nano-alumina to aluminum powder is 1:1, and the ball milling speed is 50rpm. After ball milling, magnesium powder was added to continue ball milling for 20 hours, and the mass ratio of alumina, aluminum powder, and magnesium powder was 4:4:3.

[0017] (2) Put the 6063 aluminum alloy into a clay crucible to heat and melt, and keep it at a temperature of 720°C for 10 minutes.

[0018] (3) Lower the temperature of the 6063 aluminum alloy melt in step (2) to 650°C. According to the amount of nano alumina added to the aluminum alloy slurry, the amount of the mixed powder in step (1) is 1g / Min speed was added to the 6063 aluminum alloy slurry, while mechanical stirring was introduced into the aluminum alloy slurry at a stirring speed of 300 rpm, and then the stirring treatment was continued for 15 minutes.

[0019] (4) Raise the temperature of the slurry obtained in step (3) to 680°C, ultras...

Embodiment 2

[0021] (1) Mix nano-alumina (100nm) and aluminum powder (75μm) for 50h ball milling, wherein the mass ratio of nano-alumina to aluminum powder is 1:1, and the ball milling speed is 55 rpm. After the ball milling is over, magnesium powder is added to continue ball milling for 25 hours, wherein the mass ratio of alumina, aluminum powder, and magnesium powder is 4:4:3.

[0022] (2) Put 7075 aluminum alloy into a clay crucible to heat and melt, and keep it at a temperature of 730℃ for 15 minutes.

[0023] (3) When the melt temperature of step (2) is lowered to 635°C, the amount of nano alumina added is 3wt.% of the aluminum alloy slurry, and the mixed powder of step (1) is added at 1.5g / min Into the aluminum alloy slurry, mechanical stirring was introduced into the aluminum alloy slurry at the same time, the stirring speed was 350 rpm, and then the stirring treatment was continued for 20 minutes.

[0024] (4) Raise the temperature of the slurry obtained in step (3) to 700°C, ultrasonica...

Embodiment 3

[0026] (1) Mix nano-alumina (100nm) and aluminum powder (75μm) for 50h ball milling, wherein the mass ratio of nano-alumina and aluminum powder is 1:1, and the ball milling speed is 60rpm. After the ball milling, add magnesium powder and continue ball milling for 20 hours. The mass ratio of alumina, powder, and magnesium powder is 4:4:3.

[0027] (2) Put A356 aluminum alloy into a clay crucible to heat and melt, and keep it at a temperature of 720℃ for 15 minutes.

[0028] (3) Lower the melt temperature of step (2) to 605°C, and add 1g / min of the mixed powder of step (1) to the aluminum alloy according to the amount of nano alumina added to be 1wt.% of the aluminum alloy slurry In the alloy slurry, mechanical stirring was introduced into the aluminum alloy slurry at the same time, the stirring speed was 380 rpm, and then the stirring treatment was continued for 15 minutes.

[0029] (4) Raise the temperature of the slurry obtained in step (3) to 700°C, ultrasonically treat it for 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com