Method for evaluating tissue uniformity of particles reinforced aluminum composite material

A technology for particle-reinforced aluminum and composite materials, which is applied in the direction of analyzing materials, material analysis by optical means, and measuring devices, which can solve the problems of large application limitations and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] 1) Preparation of samples: Select a representative material sample block that can correctly reflect the comprehensive performance of the material, and refer to the metal microstructure testing method (GB / T13298) for sample preparation;

[0081] 2) The preparation of the metallographic grinding surface of the sample shall be ground in strict accordance with the metal microstructure detection method to ensure that the metallographic grinding surface has no grinding marks or scratches, and shall be stored dry;

[0082] 3) Random field of view collection of the same metallographic grinding surface to ensure that the particles in the metallographic two-dimensional microstructure are clear and identifiable: select 3 metallographic photos;

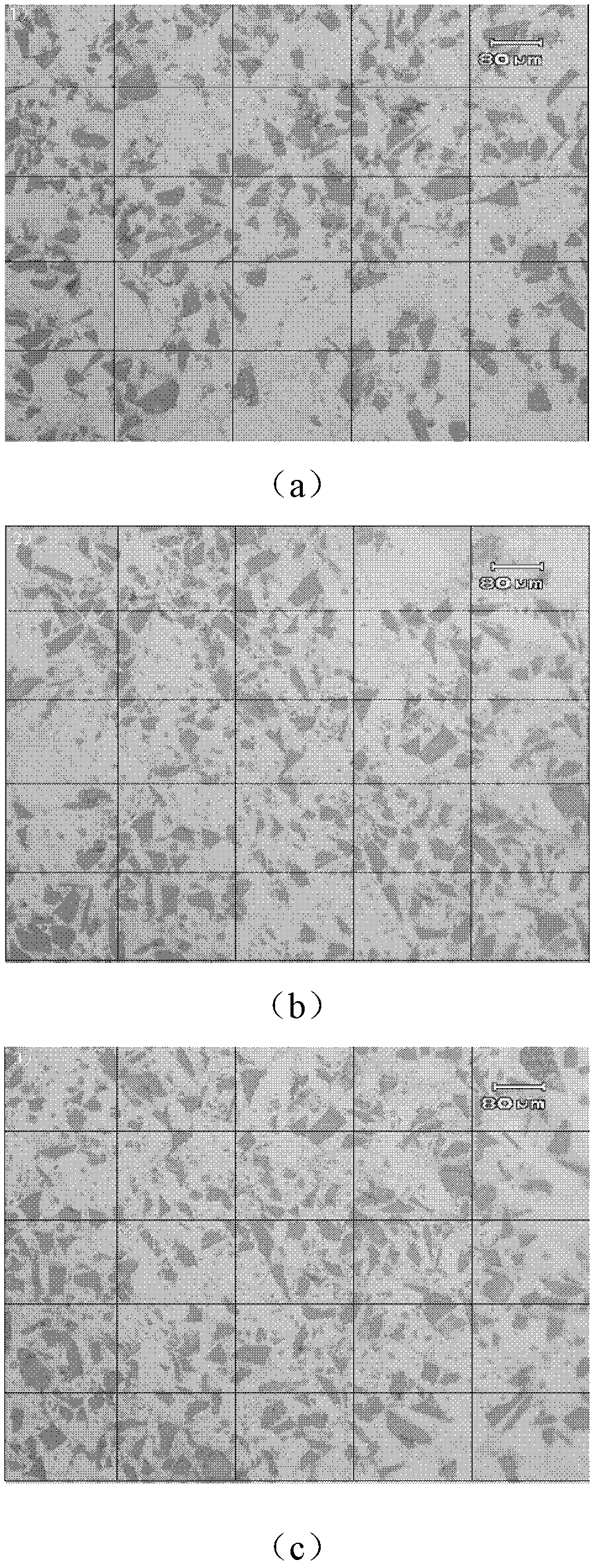

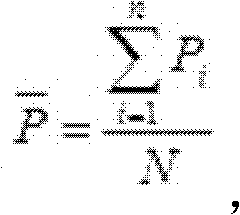

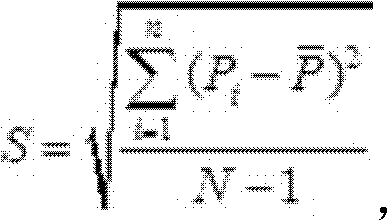

[0083] 4) Different micro-areas in the same field of view are divided into grids, taking into account the accuracy requirements and work efficiency of the measurement results: each picture is divided into 25 areas, such as figure 1 (a), (b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com