Method for preparing carbon nanotube and aluminum borate whisker hybrid reinforced aluminum-matrix composite material

A technology of aluminum borate whiskers and carbon nanotubes, which is applied in the field of preparation of micron and nanofiber hybrid reinforced aluminum matrix composite materials, can solve the problems of difficult uniform distribution of reinforcing phases, poor interface bonding, and difficult dispersion of carbon nanotubes, etc. Excellent performance, good compression resistance, good interface bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

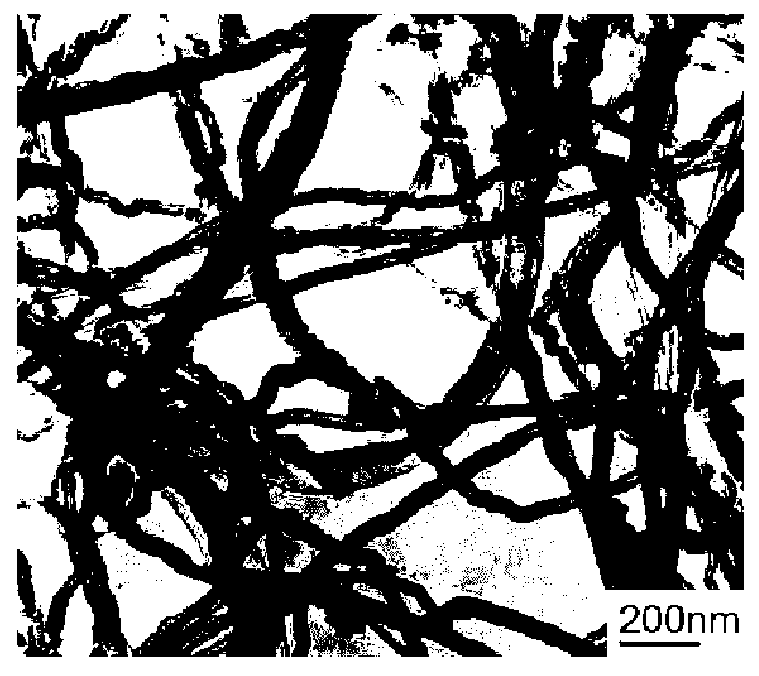

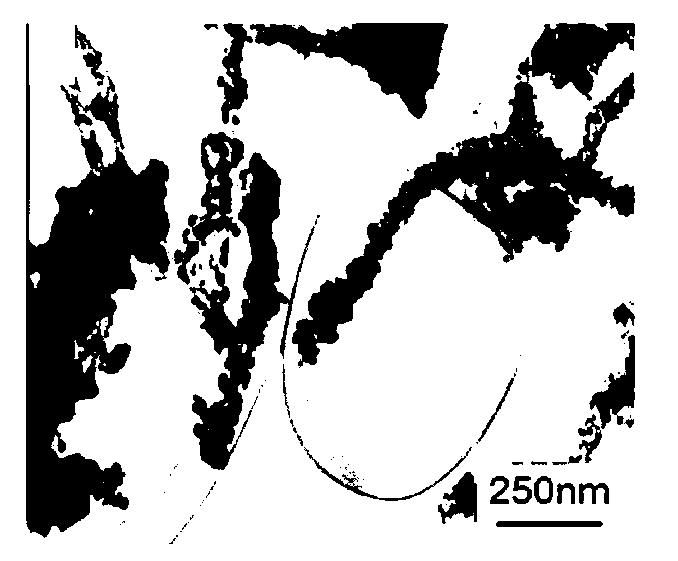

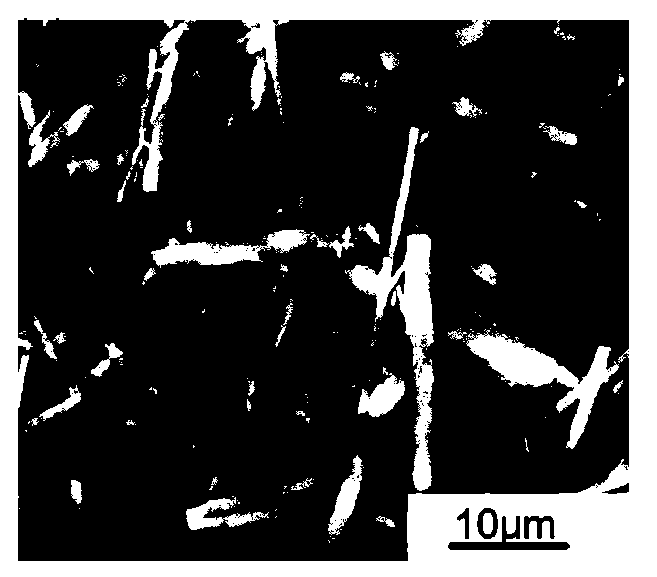

[0008] Specific Embodiment 1: In this embodiment, the preparation method of carbon nanotubes and aluminum borate whiskers hybrid reinforced aluminum matrix composite materials is carried out according to the following steps: 1. After pretreatment of carbon nanotubes and aluminum borate whiskers, wet mixing, wet mixing The mixing temperature is 80-100°C, wherein the weight ratio of carbon nanotubes and aluminum borate whiskers is 2-5: 34-40; 2. Pour the mixture in step 1 into the prefabricated block pressing mold, and then add the mixture unidirectionally Then pressurize the mixture in one direction within 5 to 10 minutes to a pressure of 3 to 5 MPa, and hold the pressure for 5 to 12 hours to obtain a prefabricated block; 3. Put the prefabricated block in a drying oven for drying, first at 60°C Conditional drying for 1.5 to 2.5 hours, then raise the temperature to 80°C for 1.5 to 2.5 hours, then raise the temperature to 95°C for 0.5 to 1.5 hours, then raise the temperature to 12...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that: the wet mixing temperature in step 1 is 85-95°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 in that: the wet mixing temperature in step 1 is 85°C. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com