Method for preparing nano slabby aluminium borate whisker by hydrothermal method

A technology of aluminum borate whiskers and nanoplates, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of backward production technology of boron products, poor comprehensive utilization of resources, and low added value of products, and achieve remarkable results Economic benefits, high product quality, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

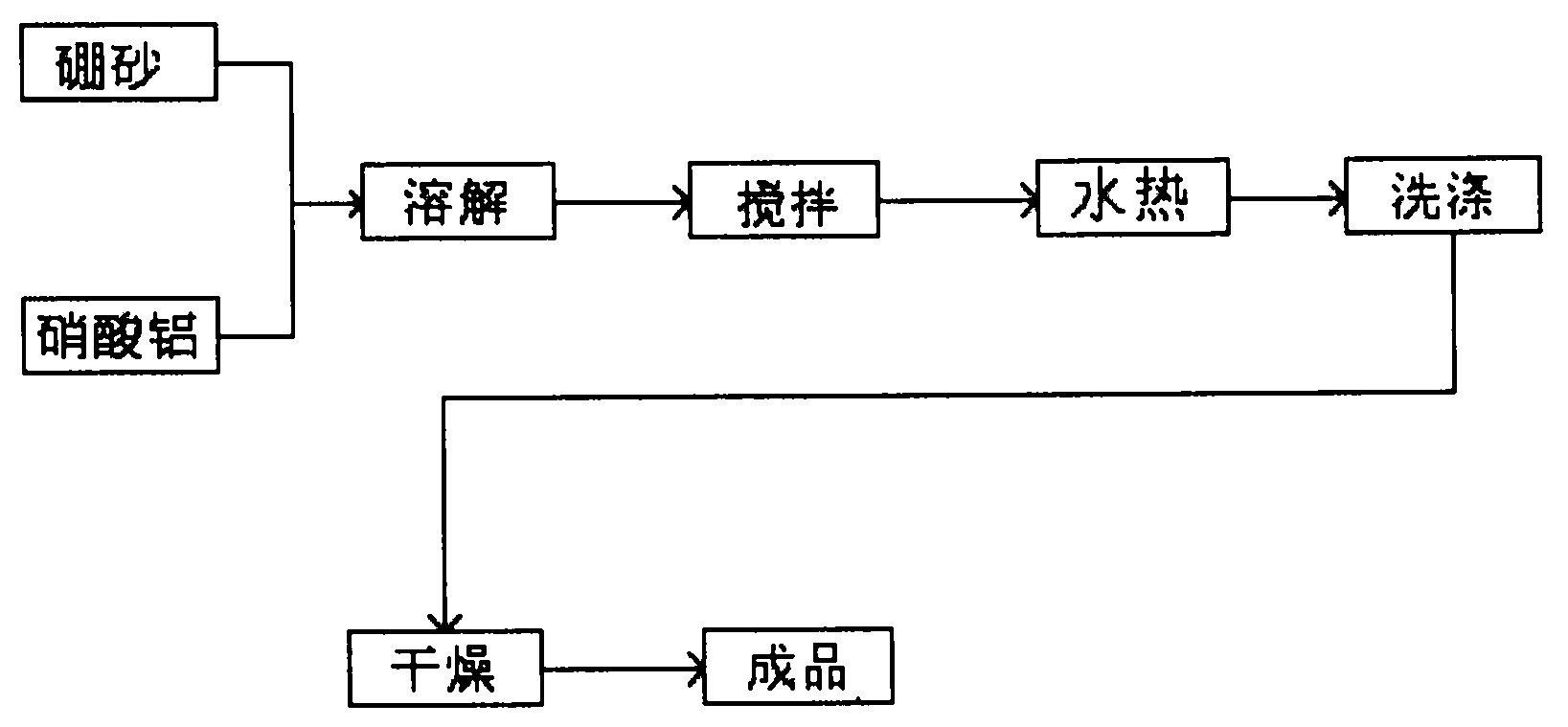

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

[0014] The method for preparing nano-plate aluminum borate whiskers in the present invention is a method for preparing whiskers with high elastic modulus, good mechanical strength, heat resistance, chemical resistance, acid resistance, electrical insulation, neutron absorption performance, Production technology of nanoplate (ribbon) aluminum borate whiskers covalent to metal. It is not only used in heat insulation, heat-resistant and corrosion-resistant materials, but also can be used as a reinforcing agent for thermoplastic resins, thermosetting resins, cement, ceramics and metals. It can also be used to strengthen metal bases (aluminum base, magnesium base), ceramic bases, plastics, glass, fibers, coatings, etc.

[0015] 1. Basic principle of the present invention

[0016] Combined with the characteristics of the hydrothermal production process, mix borax and alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com